Cov Tshuaj Masterbatch Tiv Thaiv Kev Sib Txhuam Rau Cov Khau Hauv Qab - Daws Cov Teeb Meem Kev Hnav Yam Tsis Muaj Kev Txo Qhov Xis Nyob

Txhim kho kev ruaj khov, kev nplij siab, thiab kev ua haujlwm tau zoo nrog SILIKE Anti-Abrasion Solutions rau Khau Compounds

Hauv kev tsim khau, qhov ruaj khov ntawm cov khau sab nraud yog qhov tseem ceeb uas cuam tshuam ncaj qha rau qhov zoo ntawm cov khoom, lub koob npe nrov, thiab kev txaus siab ntawm cov neeg siv khoom. Thaum cov khau sab hauv muaj kev sib txhuam ntau dhau, hnav sai, ua hmoov, lossis ua kom dawb ntawm qhov chaw, nws tuaj yeem ua rau:

♦Lub neej khau luv dua

♦Kev puas tsuaj ntawm qhov tsos thiab kev hnav tsis sib xws

♦Cov lus tsis txaus siab ntawm cov neeg siv khoom, kev xa rov qab, thiab kev pheej hmoo ntawm kev lav phib xaub uas nce ntxiv

Feem ntau cov hauv qab khau yog ua los ntawm cov ntaub ntawv xws li EVA, TPR, TR, TPU, PVC, thiab roj hmab vim lawv qhov yooj ywm, lub teeb yuag, thiab kev ywj pheej tsim. Txawm li cas los xij, nyob rau hauv kev sib txhuam rov qab, khoov, thiab siv ntev, cov ntaub ntawv no feem ntau qhia txog kev tiv thaiv kev sib txhuam tsis txaus thiab kev ua haujlwm tsis ruaj khov - tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov kev ntxhov siab xws li kev ua si nawv, sab nraum zoov, thiab khau ua haujlwm.

Cov txheej txheem ib txwm siv los txhim kho kev tiv thaiv kev sib txhuam feem ntau suav nrog cov khoom siv inorganic (carbon black, silica, mineral fillers), waxes, roj, cov roj nplua nyeem uas tsis muaj molecular weight, thiab cov resin systems uas muaj hardness siab dua. Cov txheej txheem no yuav muab kev txhim kho ib ntus, tab sis lawv feem ntau ua rau muaj teeb meem tshiab, xws li:

♦ Ua kom tawv dua thiab txo qhov xis nyob

♦ Kev poob ntawm elasticity thiab kev tuav zoo

♦ Kev tsiv teb tsaws chaw, tawg paj, lossis ua kom dawb

♦ Kev ruaj khov tsis zoo rau lub sijhawm ntev

Cov chaw tsim khau tam sim no xav tau cov kev daws teeb meem uas tuaj yeem txhim kho kev tiv thaiv kev sib txhuam thaum tswj hwm ckev nplij siab, kev yooj ywm, sqhov tsos ntawm qhov chaw, xim ruaj khov, pkev ruaj khov sai, thiab zoo sib xws.

Txij li xyoo 2006, SILIKE tau mob siab rau kev lag luam khau, txuas ntxiv txhim kho cov thev naus laus zis hloov kho silicone los tsim cov kev daws teeb meem tshwj xeeb tiv thaiv kev sib txhuam rau cov khau hauv qab.

SILIKE Anti-Abrasion Masterbatch tsom mus rau kev txhim kho kev tiv thaiv kev hnav ntau dua li cov txiaj ntsig ib txwm muaj ntawm cov khoom siv silicone. Nws yog ib qho kev daws teeb meem uas tau ua pov thawj, sib xws nrog cov khoom siv uas txhim kho kev tiv thaiv kev hnav yam tsis muaj kev cuam tshuam rau kev nplij siab, kev zoo nkauj, lossis kev ua haujlwm zoo.

LubSILIKE Anti-Abrasion Masterbatch NM Seriesyog ib qho tshuaj ntxiv tiv thaiv kev hnav uas tsim los rau txhua yam yas thiab roj hmab.

Cov tshuaj ntxiv no ua rau cov khau tsis yooj yim puas thiab ua rau cov khau tsis yooj yim puas thoob plaws hauv cov khau, ob qho tib si ntawm qhov chaw thiab sab hauv. Tib lub sijhawm, nws ua rau cov dej yaj thiab qhov ci ntsa iab ntawm qhov chaw, ua rau lub khau hauv qab siv tau ntev dua thaum tswj tau qhov zoo tshaj plaws ntawm kev xis nyob, kev ruaj khov, thiab kev ntseeg tau.

SILIKE Anti-Abrasion Masterbatch yog tsim rau:

● EVA & Phylon ua npuas ncauj

● TPR (Rubber Thermoplastic)

● Cov tshuaj TR

● Cov khau sab nraud TPU

● Cov hauv qab khau PVC

● Cov roj hmab NR / SBR / BR / NBR / EPDM

● Cov khoom sib xyaw ua ke ntawm khau uas tau hloov kho

Cov Tshuaj Tiv Thaiv Kev Hnav Rau Cov Khau Hauv Qab Uas Cov Chaw Tsim Khoom Siv Khau Ntseeg Siab

Raws li cov lus tawm tswv yim dav dav los ntawm cov chaw tsim khoom siv khau siv PVC, EVA, SBS, SEBS, TR, TPR, thiab cov roj hmab sib xyaw xim, SILIKE's Anti-Abrasion Masterbatch Series tau dhau los ua ib qho ntawm cov kev daws teeb meem dav dav tshaj plaws rau kev txhim kho kev hnav tsis kam ntawm cov khau sab nraud yam tsis muaj kev txi kev nplij siab lossis kev ua haujlwm.

Cov Kev daws teeb meem pom zoo rau cov khoom siv hauv qab uas tiv taus kev hnav sib txawv

NM-2T EVA Anti-Abrasion Masterbatch rau Cov Khau Tawv Ntev

Yuav Ua Li Cas Txhim Kho EVA Khau Tawv Tsis Muaj Kev Cuam Tshuam Rau Kev Xis Nyob

NM-1Y Cov Khoom Siv Tiv Thaiv Kev Hnav Khaub Ncaws rau TPR thiab TR Khau Hauv Qab

Txhim kho qhov ruaj khov ntawm sab nraud thiab kev ua haujlwm ruaj khov

LYSI-10 TPR Hnav-Tiv Thaiv & Kev Pab Ua Haujlwm

Txhim kho Kev Tiv Thaiv Kev Sib Txhuam thiab Kev Ua Haujlwm Zoo hauv TPR Khau Hauv Qab

NM-3C Cov Tshuaj Tiv Thaiv Kev Sib Txhuam Zoo Rau EPDM & Cov Roj Hmab

Kev Tiv Thaiv Kev Hnav Ntev Ntev Tsis Muaj Kev Poob Khoom Siv Kho Tshuab

NM-3 Anti-Abrasion Masterbatch rau Cov Khau Roj Hmab

Yuav Ua Li Cas Thiaj Siv Tau Lub Neej Ntev Ntawm Cov Roj Hmab Outsole Thaum Muaj Kev Sib Txhuam Ntau

NM-6 TPU Anti-Abrasion & Slip Modifier rau Cov Khoom Siv Sab Nraud Uas Ruaj Khoov

Txo Kev Sib Txhuam thiab Txhim Kho Kev Ua Tau Zoo ntawm TPU Khau Hauv Qab

Vim li cas ho xaiv SILIKE Silicone-Based Anti-Abrasion Masterbatch rau Khau Compounds?

1. Kev Tiv Thaiv Kev Siv Nyiaj Txiag Zoo ntawm Qis Dosage

Txhim kho qhov kev tiv thaiv kev sib txhuam nrog cov qib ntxiv me me (feem ntau yog 0.5–1.5%), pab cov neeg sib xyaw khau txo cov nqi tsim khoom thaum tseem tswj tau qhov xis nyob thiab kev ua tau zoo.

2. Zoo dua Filler & Pigment Dispersion

Ua kom cov khoom sib xyaw thiab cov xim pigments zoo dua, ua rau cov nplaim zoo sib xws, cov khoom siv kho tshuab zoo ib yam, thiab tsawg dua qhov tsis zoo thaum lub sijhawm molding lossis extrusion.

3. Tsis muaj kev cuam tshuam rau qhov nyuaj lossis elasticity

Khaws qhov ruaj khov, rov qab los, thiab yooj ywm qub—qhov tseem ceeb rau kev nplij siab, kev tuav, thiab kev xis nyob ntawm tus neeg hnav.

4. Txhim Kho Xim Lub Zog & Qhov Nto Zoo Li Cas

Ua kom cov xim ci ntsa iab thiab qhov ci ntsa iab tsis muaj paj, dawb, lossis pom qhov tsis zoo tom qab puas.

5. Kev Tiv Thaiv Kev Hnav Khaub Ncaws Thoob Plaws Cov Khoom Siv

Muab kev tiv thaiv kev txhuam tsis tu ncua los ntawm qhov chaw mus rau sab hauv, ua kom ntseeg tau tias nws ruaj khov ntev rau tag nrho cov khau sab nraud.

6. Kev Ua Haujlwm Zoo Dua

Txhim kho cov dej ntws, kev sau pwm, thiab kev tso tawm kev ua tau zoo, txo cov teeb meem ua tiav thiab txhim kho kev ruaj khov ntawm kev tsim khoom.

7. Lub neej khau ntev dua nrog kev nplij siab sib npaug

Ua kom lub hauv paus sab nraud siv tau ntev dua thaum tseem khaws qhov yooj ywm, xis nyob, thiab kev ruaj khov ntawm cov qauv.

8. Kev Tsim Khoom Uas Muaj Lub Luag Haujlwm Rau Ib Puag Ncig & Ruaj Khov

Cov khoom siv silicone, tsis txav chaw, tsis muaj ntxhiab tsw qab uas txhawb nqa kev ua raws li ib puag ncig thiab kev tsim khau ruaj khov.

9. Kev Ua Tau Zoo Hauv Kev Ntsuas Kev Lag Luam

Zoo rau kev sim tshuaj ntsuam DIN, ASTM, NBS, AKRON, SATRA, thiab GB.

Cov Kev Tshawb Fawb Txog Cov Ntaub Ntawv & Cov Khoom Siv

Cov Kev Kawm Txog Kev Tiv Thaiv Kev Sib Txhuam Khau & Cov Khoom Siv

Kev Ua Tau Zoo Tiv Thaiv Kev Sib Txhuam Hauv Cov Khau Sib Xyaws Thoob Ntiaj Teb

Cov txiaj ntsig tseem ceeb:

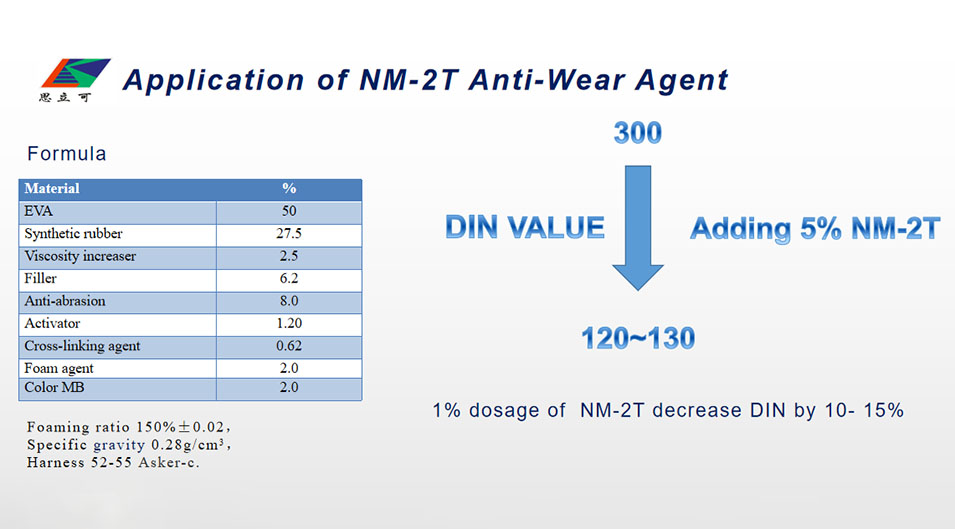

• Txhim kho qhov kev tiv thaiv kev sib txhuam nrog txo qhov kev sib txhuam ntawm cov hauv qab khau EVA, txo qhov kev poob ntawm kev sib txhuam thaum hnav txhua hnub thiab ua kom lub neej ntev ntawm kev ua kis las, kev hnav khaub ncaws ib txwm, thiab kev ua si sab nraum zoov.

• 1% NM-2T txo qhov kev puas tsuaj ntawm DIN los ntawm 10–15%.

• 5% NM-2T tuaj yeem txo qhov kev puas tsuaj ntawm DIN los ntawm ~ 300 mus rau 120–130.

• Txhim kho kev ua haujlwm thiab qhov zoo nkauj ntawm qhov chaw: txhim kho kev yaj, kev sau pwm, thiab qhov ci ntawm qhov chaw yam tsis muaj kev cuam tshuam rau kev nplij siab.

• Tsis muaj kev cuam tshuam rau qhov nyuaj, txhim kho me ntsis cov khoom siv kho tshuab

Cov qauv tsim uas zoo rau ib puag ncig, tsis yog kev tsiv teb tsaws chaw ua raws li cov cai thoob ntiaj teb.

• Siv tau zoo rau kev sim kev txhuam ntawm DIN, ASTM, NBS, AKRON, SATRA, thiab GB.

Cov txiaj ntsig tseem ceeb:

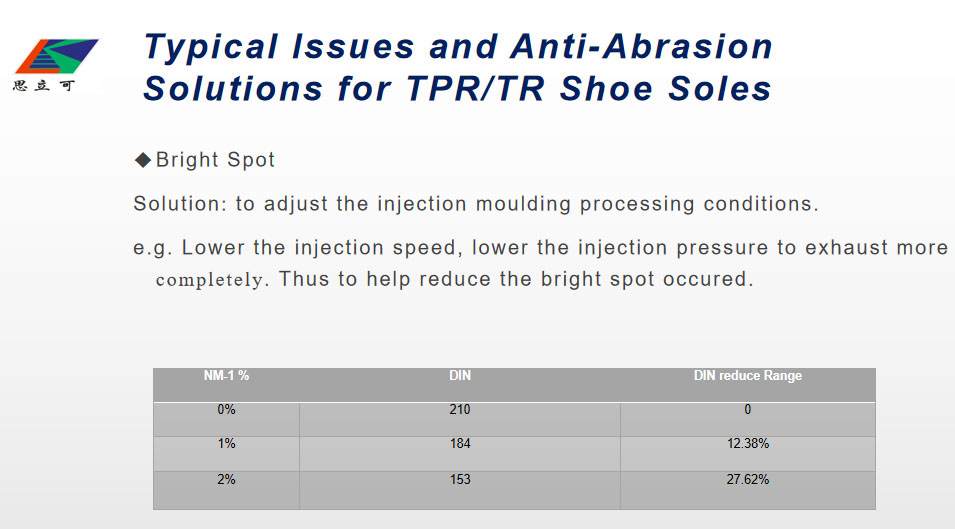

• Txo qhov kev sib txhuam ntawm cov hauv qab TPR/TR, ua kom muaj kev tiv thaiv kev hnav rau kev ua kis las, kev hnav khaub ncaws yooj yim, thiab kev hnav sab nraum zoov.

• Ntawm 1% ntxiv, NM-1 tuaj yeem txo qhov kev puas tsuaj ntawm DIN los ntawm kwv yees li 12.38%.

• Txhim kho kev ruaj khov ntawm kev ua haujlwm thiab qhov chaw tiav: txhim kho kev yaj, kev sau pwm, thiab kev ci ntsa iab tas li yam tsis cuam tshuam rau kev xis nyob.

• Tswj tau qhov tawv thiab xim ruaj khov yam tsis muaj kev cuam tshuam rau cov khoom sib xyaw.

• Cov qauv tsim uas zoo rau ib puag ncig ua raws li cov qauv khau thoob ntiaj teb.

• Tau ua pov thawj hauv DIN, ASTM, NBS, AKRON, SATRA, thiab GB kev ntsuam xyuas kev sib txhuam.

• Tshuaj tsawg, pheej yig, tsim nyog rau TPR, TR, SBS, thiab cov xim sib xyaw.

Cov txiaj ntsig tseem ceeb:

• Txhim kho qhov kev tiv thaiv kev sib txhuam zoo heev, txo qhov kev sib txhuam ntawm cov hauv qab khau TR/TPR.

• Txhim kho kev ua haujlwm thiab qhov zoo nkauj ntawm qhov chaw

• Tsis muaj kev cuam tshuam rau qhov tawv lossis xim, khaws cia cov khoom qub.

• Cov qauv tsim uas zoo rau ib puag ncig uas tsim nyog rau kev tsim khau uas ruaj khov.

• Ua raws li DIN, ASTM, NBS, AKRON, SATRA, GB kev ntsuam xyuas kev sib txhuam.

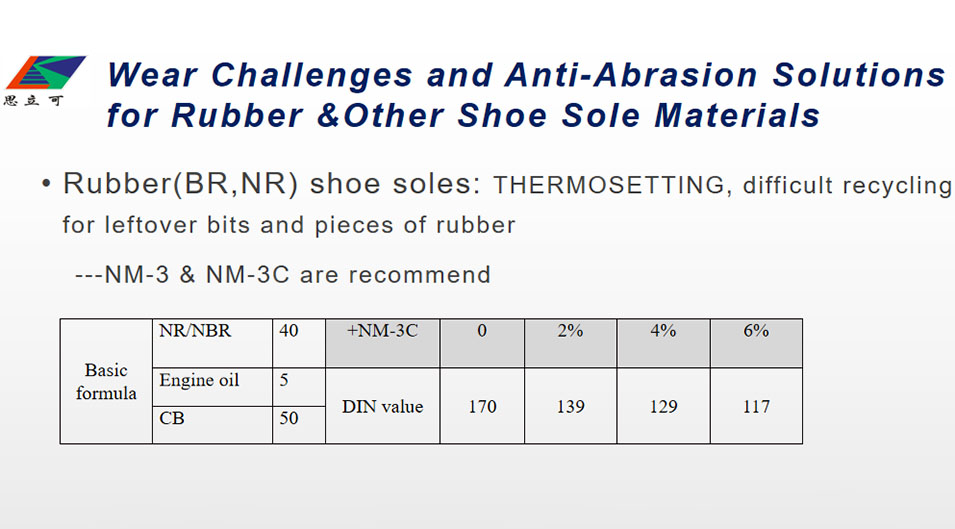

Cov txiaj ntsig tseem ceeb:

• Txo qhov kev puas tsuaj ntau heev, ua rau lub hauv paus sab nraud siv tau ntev dua

• Ntawm 2% ntxiv, NM-3C tuaj yeem txo qhov DIN abrasion tus nqi los ntawm kwv yees li 170 mus rau 139

• Tsis muaj kev cuam tshuam rau cov khoom siv kho tshuab, qhov nyuaj, lossis qhov ywj pheej

• Txhim kho kev ntws, kev tso pwm tawm, thiab kev ua tiav ntawm qhov chaw

• Txhim kho kev ruaj khov yam tsis muaj kev cuam tshuam rau kev xis nyob ntawm khau

• Zoo rau ib puag ncig thiab sib xws nrog cov qauv tsim khau thoob ntiaj teb

NM-3 Cov Tshuaj Masterbatch Tiv Thaiv Kev Sib Txhuam Rau Cov Khau Roj Hmab Xim - Txhim Kho Kev Tiv Thaiv Kev Hnav Thiab Ntev Lub Neej Outsole

Cov txiaj ntsig tseem ceeb:

• Txhim kho kev tiv taus kev sib txhuam thiab txo qhov kev sib txhuam ntawm cov xim roj hmab khau hauv qab.

• Txhim kho kev ua haujlwm thiab qhov zoo nkauj ntawm qhov chaw, ua rau du thiab ci ntsa iab.

• Cov qauv tsim uas zoo rau ib puag ncig, ua raws li cov kev cai ntawm kev nyab xeeb khau.

• Tsis muaj kev cuam tshuam rau qhov tawv lossis xim, khaws cia cov khoom qub.

• Kuaj thiab ua raws li DIN, ASTM, NBS, AKRON, SATRA, GB kev ntsuam xyuas kev sib txhuam.

• Zoo rau SBS thiab SBS-compatible resin systems hauv cov roj hmab outsoles.

TPU Khau Tawv Uas Tiv Thaiv Kev Hnav Khaub Ncaws NM-6 — Anti-Abrasion Masterbatch rau Khau

Cov txiaj ntsig tseem ceeb:

• Txhim kho kev tiv thaiv kev sib txhuam thiab txo qhov kev hnav ntawm TPU outsole

• Ntawm 0.5% ntxiv rau hauv TPU (hardness 85A), NM-6 tuaj yeem txo qhov DIN abrasion value ntawm 100 mus rau 60.

• Ua kom cov dej yaj zoo dua, cov pwm tawm los, thiab qhov kawg zoo nkauj dua, ua kom cov txheej txheem ua haujlwm tau zoo dua.

• Cov tshuaj ntxiv uas zoo rau ib puag ncig uas tsim nyog rau kev tsim khau uas ruaj khov.

• Ua raws li DIN, ASTM, NBS, AKRON, SATRA, GB kev ntsuam xyuas kev sib txhuam.

Cov Txiaj Ntsig ntawm Kev Ntsuas Kev Sib Txhuam thiab Kev Ntsuam Xyuas Kev Ua Tau Zoo

Cov Kws Tsim Khau Hais Li Cas Txog Peb Cov Kev daws teeb meem tiv thaiv kev sib txhuam

★★★★★

NM-2T - EVA Khau Sab Nraud

"Hauv peb cov khau EVA sib xyaw ua ke, kev hnav thiab kev puas tsuaj ntawm cov khau sab nraud yog qhov teeb meem loj. Cov nqi puas tsuaj ntawm DIN feem ntau yog txij li 200–300, uas cuam tshuam tsis zoo rau lub neej khau thiab kev nplij siab ntawm tus neeg siv. Siv SILIKE NM-2T, txawm tias 1% koob tshuaj kuj txo DIN los ntawm 10–15%. Nrog 5% NM-2T, peb txo cov nqi DIN los ntawm 300 mus rau 120–130, ua rau lub neej kev pabcuam ntawm cov khau sab nraud ntev dua. Cov khoom siv tswj tau qhov nyuaj thiab kev nplij siab qub, thaum txhim kho qhov zoo li ntawm qhov chaw thiab kev ntseeg siab tag nrho."

— John Smith, Chaw Tsim Khoom Siv Khau EVA

★★★★★

NM-3C Tshuaj Tiv Thaiv Kev Hnav Rau Cov Roj Hmab EPDM — Txhim Kho Kev Tiv Thaiv Kev Sib Txhuam & Ntev Lub Neej Sab Nraud

Peb tab tom nrhiav ib yam khoom siv tiv thaiv kev hnav uas muaj kev tiv thaiv kev sib txhuam zoo heev rau cov khoom sib xyaw NBR nrog 90 Shore A hardness. Tom qab siv SILIKE NM-3C, tsim tshwj xeeb rau cov roj hmab resins, peb cov khoom sib xyaw tau ua pov thawj tias muaj kev tiv thaiv kev sib txhuam zoo dua hauv NBR systems. Cov hauv qab tiav lawm khaws cia lawv cov tawv thiab xim qub, thaum lub sijhawm ua haujlwm ntev thiab lub neej ntev tau txhim kho zoo heev. NM-3C kuj tau txhim kho kev ua haujlwm, ua kom ntseeg tau tias cov pwm du thiab zoo ib yam yam tsis cuam tshuam rau peb cov xwm txheej tsim khoom.

— Juan Pérez, Tus Thawj Saib Xyuas Kev Tshawb Fawb thiab Kev Txhim Kho Cov Roj Hmab, Chaw Tsim Khau

★★★★★

NM-3 - Tus Neeg Sawv Cev Tiv Thaiv Kev Hnav Rau Cov Roj Hmab Xim Sab Hauv

"Hauv peb cov EPDM outsole compounding, kev tswj hwm kev tiv thaiv kev sib txhuam thaum khaws cia qhov nyuaj Shore A yeej ib txwm yog qhov nyuaj. Cov khoom siv fillers ib txwm feem ntau ua rau qhov zoo ntawm qhov chaw puas tsuaj thiab txo qhov ruaj khov. Tom qab qhia SILIKE NM-3C, peb pom tias qhov kev sib txhuam txo qis, qhov ci ntsa iab ntawm qhov chaw zoo dua, thiab tsis muaj kev hloov pauv ntawm qhov nyuaj. Cov outsole tiav lawm tam sim no ua tau raws li DIN, ASTM, thiab SATRA cov qauv thaum tswj hwm kev ua haujlwm zoo heev, txo cov teeb meem tso pwm, thiab ua kom lub neej khoom ntev dua."

— Michael Tan, Chaw Tsim Khoom Siv Khau Roj Hmab

★★★★★

NM-1Y - Tus Neeg Sawv Cev Tiv Thaiv Kev Hnav Rau TPR/TR Outsoles

"Hauv peb cov khau ua si TPR/TR, kev ua tiav qhov kev tiv thaiv kev sib txhuam sib npaug yog qhov teeb meem rov tshwm sim, tshwj xeeb tshaj yog nyob rau hauv kev khoov thiab kev sib txhuam rov ua dua. Ntxiv 2–3% NM-1Y ua rau muaj kev txo qis ntawm cov nqi kev sib txhuam DIN, kev ntws zoo dua, thiab qhov chaw tiav du dua. Kev ua tiav tau ruaj khov dua, thiab cov khau khaws cia lawv qhov kev nplij siab thiab kev tsim qauv zoo thoob plaws lub sijhawm hnav ntev."

— Li Wei, Tus Tsim Kho Khau Ua Si

★★★★★

NM-6 - Tus Neeg Sawv Cev Tiv Thaiv Kev Hnav Rau TPU Outsoles

"Cov khau TPU sab nraud feem ntau yuav muaj COF ntau thiab ua rau puas sai, ua rau lub neej khoom luv dua. Tom qab siv NM-6 tsuas yog 1-2% xwb, peb pom tias COF thiab kev puas tsawg dua. Cov khoom siv kho tshuab thiab xim ntawm cov khoom sib xyaw tseem tsis hloov pauv, kev ua haujlwm du dua, thiab kev tso pwm tawm zoo dua. Cov neeg siv kawg tau tshaj tawm tias cov khau sab nraud siv tau ntev dua, xis nyob, thiab pom tseeb."

— Samantha Lee, Chaw Tsim Khau TPU

★★★★★

LYSI-10 - Kev Pab Tiv Thaiv Kev Sib Txhuam & Kev Ua Haujlwm rau TPR Cov Tshuaj Sib xyaw

"Cov khoom sib xyaw TPR/TR feem ntau raug kev txom nyem los ntawm kev tsis kam tiv taus kev sib txhuam thiab qhov zoo ntawm qhov chaw tsis sib xws thaum lub sijhawm extrusion ceev ceev. Kev koom ua ke 3% LYSI-10 rau hauv peb cov qauv TPR PS-compatible tau txhim kho kev tiv taus kev sib txhuam, txo qis qhov kev sib txhuam, thiab txhim kho qhov ci ntsa iab ntawm qhov chaw. Kev ruaj khov ntawm cov kab extrusion tau zoo dua, cov kua qaub ntawm cov tuag tau txo qis, thiab peb tau txais cov khau zoo sib xws, tsis cuam tshuam rau xim lossis qhov nyuaj."

— Rajesh Kumar, Kws Tshwj Xeeb Txog Khau

Txhim Kho Kev Ua Haujlwm Zoo, Ntev Lub Neej Khau, thiab Sib Npaug Kev Xis Nyob nrog Kev Ntseeg Tau