Cov tshuaj silicone ntxiv txhim kho PS ua haujlwm thiab du nto li cas?

Cov tshuaj silicone ntxiv txhim kho PS ua haujlwm thiab du nto li cas?

PS ua thiab du nto, Cov Khoom Siv Silicone, Silicone Masterbatch,

Kev piav qhia

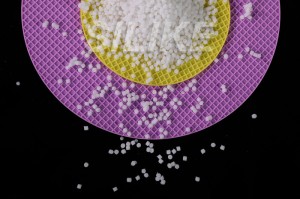

Silicone Masterbatch(Siloxane Masterbatch) LYSI-410 yog cov pelletized formulation nrog 50% ultra high molecular weight siloxane polymer dispersed hauv High impact polystyrene (HIPS). Nws yog dav siv ua cov khoom siv ua haujlwm zoo hauv PS compatible resin system los txhim kho cov khoom ua haujlwm thiab hloov kho qhov zoo ntawm qhov chaw.

Piv rau cov khoom siv silicone / Siloxane uas muaj qhov hnyav tsawg dua, xws li roj Silicone, kua silicone lossis lwm yam khoom siv ua tiav, SILIKESilicone MasterbatchLYSI series xav tias yuav muab cov txiaj ntsig zoo dua, piv txwv li,. Tsawg dua qhov ntsia hlau slippage, zoo dua pwm tso tawm, txo cov kua qaub ntawm pwm, qis dua coefficient ntawm kev sib txhuam, tsawg dua xim thiab luam ntawv teeb meem, thiab ntau yam kev ua tau zoo.

Cov Txheej Txheem Tseem Ceeb

| Qib | LYSI-410 |

| Qhov tsos | Cov pob zeb dawb |

| Cov ntsiab lus silicone % | 50 |

| Cov roj hmab puag | HIPS |

| Cov ntsuas yaj (230 ℃, 2.16KG) g / 10 feeb | 13.0 (tus nqi ib txwm muaj) |

| Cov Tshuaj Noj (w/w) | 0.5~5 |

Cov txiaj ntsig

(1) Txhim kho cov khoom ua tiav suav nrog kev muaj peev xwm ntws zoo dua, txo cov kua dej tawm ntawm extrusion, tsawg dua extruder torque, zoo dua molding filling & tso tawm

(2) Txhim kho qhov zoo ntawm qhov chaw xws li qhov chaw plam, txo qhov sib txhuam ntawm Coefficient

(3) Kev puas tsuaj ntau dua thiab kev khawb tsis kam

(4) Kev xa khoom sai dua, txo cov khoom puas tsuaj.

(5) Txhim kho kev ruaj khov piv nrog cov kev pabcuam ua haujlwm ib txwm muaj lossis cov roj nplua nyeem

Cov ntawv thov

(1) Khau TPR/TR

(2) Cov khoom siv thermoplastic elastomers

(3) Cov yas ua vaj tse

(4) Lwm cov tshuab PS uas siv tau

Yuav siv li cas

SILIKE LYSI series silicone masterbatch yuav raug ua tiav tib yam li cov resin carrier uas lawv ua raws. Nws tuaj yeem siv rau hauv cov txheej txheem sib xyaw ua ke zoo li Single / Twin ntsia hlau extruder, txhaj tshuaj molding. Kev sib xyaw ua ke nrog cov polymer pellets tshiab yog qhov pom zoo.

Pom zoo kom noj ntau npaum li cas

Thaum ntxiv rau polyethylene lossis cov thermoplastic zoo sib xws ntawm 0.2 txog 1%, kev ua tiav zoo dua thiab kev ntws ntawm cov resin yog qhov xav tau, suav nrog kev sau pwm zoo dua, tsawg dua extruder torque, cov roj nplua nyeem sab hauv, tso pwm thiab kev xa khoom sai dua; Ntawm qib ntxiv siab dua, 2 ~ 5%, cov khoom nto zoo dua xav tau, suav nrog lubricity, plam, qis dua coefficient ntawm kev sib txhuam thiab ntau dua mar / khawb thiab abrasion tsis kam.

Pob khoom

25Kg / hnab, hnab ntawv ua tes ua

Kev Khaws Cia

Kev thauj mus los ua cov tshuaj tsis muaj kev phom sij. Khaws cia rau qhov chaw txias thiab muaj cua nkag zoo.

Lub neej txee

Cov yam ntxwv qub tseem nyob ruaj khov rau 24 lub hlis txij li hnub tsim khoom, yog tias khaws cia rau hauv qhov chaw cia khoom pom zoo.

Chengdu Silike Technology Co., Ltd yog lub chaw tsim khoom thiab tus neeg muag khoom ntawm cov khoom siv silicone, uas tau mob siab rau R & D ntawm kev sib xyaw ua ke ntawm Silicone nrog thermoplastics rau 20+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnPS sheet is a material made of general-purpose polystyrene resin, some of our PS material clients told us when their downstream client produces 40 thread thickness polystyrene sheets if 50 sheets are cut at the same time, the surface of the products will have fuzz flash issues. when added SILIKE silicone additive to polystyrene at 2.0%, improved processing and flow of the resin are expected, in addition, the final PS sheet has good toughness, smooth surface that can cut PS sheet in a wanton shape, get good kerf and smooth edge.

COV KHOOM SIV SILICONE DAWB THIAB COV QAUV Si-TPV NTAU TSHAJ 100 QIB

Hom qauv

$0

- 50+ xyoo

Qib Silicone Masterbatch

- 10+ xyoo

qib Silicone Hmoov

- 10+ xyoo

qib Anti-scratch Masterbatch

- 10+ xyoo

Qib Anti-abrasion Masterbatch

- 10+ xyoo

Qib Si-TPV

- 8+

qib Silicone Wax

-

Xov tooj

-

Email

-

Whatsapp

Whatsapp

-

Sab saum toj

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur