Yuav ua li cas los txhim kho qhov khawb tsis kam ntawm polypropylene

Yuav ua li cas los txhim kho qhov khawb tsis kam ntawm polypropylene,

Cov tshuaj ntxiv tiv thaiv khawb, silicone masterbatch tiv thaiv khawb, txhim kho qhov khawb tsis kam,

Kev piav qhia

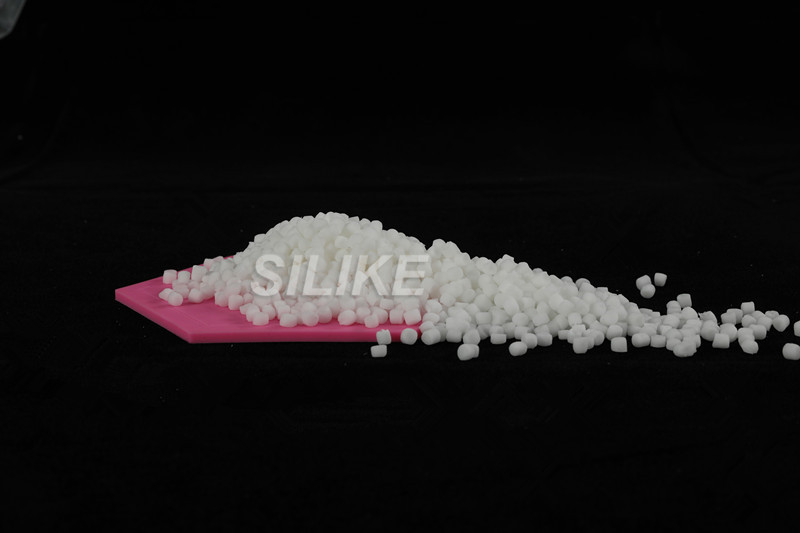

Silicone masterbatch LYSI-306C yog qhov hloov kho dua tshiab ntawm LYSI-306, muaj kev sib raug zoo nrog Polypropylene (CO-PP) matrix - Ua rau muaj kev sib cais qis dua ntawm qhov chaw kawg, qhov no txhais tau tias nws nyob ntawm qhov chaw ntawm cov yas kawg yam tsis muaj kev tsiv teb tsaws chaw lossis exudation, txo cov pos huab, VOCS lossis Odors. LYSI-306C pab txhim kho cov khoom tiv thaiv kev khawb ntawm cov tsheb sab hauv, los ntawm kev muab kev txhim kho hauv ntau yam xws li Zoo, Kev Laus, Kev Xav Tes, Txo cov hmoov av ... thiab lwm yam. Haum rau ntau yam ntawm Automotive sab hauv nto, xws li: Cov qhov rooj vaj huam sib luag, Dashboards, Center Consoles, cov cuab yeej vaj huam sib luag.

Cov Txheej Txheem Tseem Ceeb

| Qib | LYSI-306C |

| Qhov tsos | Cov pob zeb dawb |

| Cov ntsiab lus silicone % | 50 |

| Cov roj hmab puag | PP |

| Cov ntsuas yaj (230 ℃, 2.16KG) g / 10 feeb | 2 (tus nqi ib txwm muaj) |

| Cov Tshuaj Noj (w/w) | 1.5~5 |

Cov txiaj ntsig

Silicone masterbatch LYSI-306C ua haujlwm ua tus neeg sawv cev tiv thaiv kev khawb thiab kev pab ua haujlwm. Qhov no muab cov khoom tswj tau thiab sib xws nrog rau cov qauv tsim tshwj xeeb.

(1) Txhim kho cov khoom tiv thaiv khawb ntawm TPE, TPV PP, PP/PPO Talc puv cov kab ke.

(2) Ua haujlwm ua tus txhim kho kev sib txhuam mus tas li

(3) Tsis muaj kev tsiv teb tsaws chaw

(4) Kev tso pa tawm VOC tsawg

Yuav siv li cas

Cov theem ntxiv ntawm 0.5 ~ 5.0% yog qhov pom zoo. Nws tuaj yeem siv rau hauv cov txheej txheem sib xyaw ua ke zoo li Single / Twin ntsia hlau extruders, txhaj tshuaj molding. Ib qho kev sib xyaw ua ke nrog cov polymer pellets tshiab yog qhov pom zoo.

Pob khoom

25Kg / hnab, hnab ntawv ua tes ua

Kev Khaws Cia

Kev thauj mus los ua cov tshuaj tsis muaj kev phom sij. Khaws cia rau qhov chaw txias thiab muaj cua nkag zoo.

Lub neej txee

Cov yam ntxwv qub tseem nyob ruaj khov rau 24 lub hlis txij li hnub tsim khoom, yog tias khaws cia rau hauv qhov chaw khaws cia pom zoo. Kev txhim kho qhov tsis kam khawb ntawm polypropylene (PP) yog qhov tseem ceeb rau ntau yam lag luam, los ntawm kev tsim tsheb mus rau kev tsim khoom siv kho mob. PP yog cov thermoplastic polymer uas tsis hnyav, muaj zog, thiab tiv taus ntau yam tshuaj lom neeg. Txawm li cas los xij, nws tuaj yeem yooj yim khawb thiab puas. Hmoov zoo, muaj ntau txoj hauv kev los txhim kho qhov tsis kam khawb ntawm PP.

1. Ntxiv Cov Khoom Siv Sau: Ntxiv cov khoom siv sau xws li cov iav fibers lossis talc tuaj yeem pab txhim kho qhov tsis kam khawb ntawm PP. Cov khoom siv sau ua lub buffer ntawm qhov chaw ntawm cov khoom thiab txhua yam kev sib txhuam uas yuav kov nws. Qhov no pab txo qhov kev puas tsuaj los ntawm kev khawb thiab kev sib txhuam.

2. Ntxiv cov tshuaj tiv thaiv khawb, xws li cov tshuaj silicone masterbatch tiv thaiv khawb,

Kev siv cov tshuaj silicone masterbatch tiv thaiv kev khawb hauv cov ntaub ntawv PP, Ua ntej, tuaj yeem txo cov lej ntawm cov khawb uas tshwm sim ntawm qhov chaw ntawm cov ntaub ntawv. Qhov no yog vim tias cov khoom me me silicone hauv masterbatch ua haujlwm ua cov roj nplua nyeem, uas pab txo kev sib txhuam ntawm cov chaw thiab yog li txo qhov khawb. Tsis tas li ntawd, nws kuj tseem tuaj yeem pab ua kom muaj zog thiab ruaj khov ntawm cov ntaub ntawv PP, nrog rau txhim kho lawv cov cua sov tiv taus thiab UV ruaj khov.

3. Siv Cov Khoom Sib Xyaws: Kev sib xyaw PP nrog lwm cov ntaub ntawv xws li polyethylene (PE) lossis polycarbonate (PC) kuj tseem tuaj yeem pab txhim kho nws qhov kev tiv thaiv khawb. Kev ntxiv cov ntaub ntawv no pab tsim cov khoom siv ruaj khov dua uas muaj peev xwm tiv taus cov zog abrasive yam tsis raug puas tsuaj lossis khawb.

4. Siv Cov Txheej Txheem: Kev siv cov txheej txheem xws li xim lossis cov xim pleev xim kuj tseem tuaj yeem pab txhim kho qhov tsis kam khawb ntawm PP. Cov txheej txheem no muab ib txheej ntxiv ntawm kev tiv thaiv tiv thaiv kev khawb thiab kev hloov pauv, pab kom cov khoom zoo li tshiab rau lub sijhawm ntev dua.

COV KHOOM SIV SILICONE DAWB THIAB COV QAUV Si-TPV NTAU TSHAJ 100 QIB

Hom qauv

$0

- 50+ xyoo

Qib Silicone Masterbatch

- 10+ xyoo

qib Silicone Hmoov

- 10+ xyoo

qib Anti-scratch Masterbatch

- 10+ xyoo

Qib Anti-abrasion Masterbatch

- 10+ xyoo

Qib Si-TPV

- 8+

qib Silicone Wax

-

Xov tooj

-

Email

-

Whatsapp

Whatsapp

-

Sab saum toj

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur