Cov Khoom Siv Ntxiv Rau Lubricant (Cov Khoom Pab Ua Haujlwm) Rau WPC SILIMER 5400

Kev piav qhia

Cov tshuaj ntxiv no yog tsim tshwj xeeb rau kev ua thiab tsim cov PE thiab PP WPC (cov khoom siv ntoo yas) xws li WPC decking, WPC laj kab, thiab lwm yam WPC composites, thiab lwm yam. Lub hauv paus ntawm cov tshuaj ntxiv no rau WPC yog hloov kho polysiloxane, muaj cov pab pawg polar active, sib raug zoo heev nrog cov resin thiab hmoov ntoo, thaum ua thiab tsim khoom tuaj yeem txhim kho kev sib kis ntawm cov hmoov ntoo, tsis cuam tshuam rau qhov sib xws ntawm cov compatibilizers hauv lub kaw lus, tuaj yeem txhim kho cov khoom siv kho tshuab ntawm cov khoom. Tus neeg sawv cev tso tawm no rau WPC composites zoo dua li WPC wax lossis WPC stearate additives thiab pheej yig, lubrication zoo heev, tuaj yeem txhim kho cov khoom ua matrix resin, tab sis kuj tuaj yeem ua rau cov khoom du, muab koj cov ntoo yas composites ib daim duab tshiab.

Cov Lus Qhia Txog Khoom

| Qib | SILIMER 5400 |

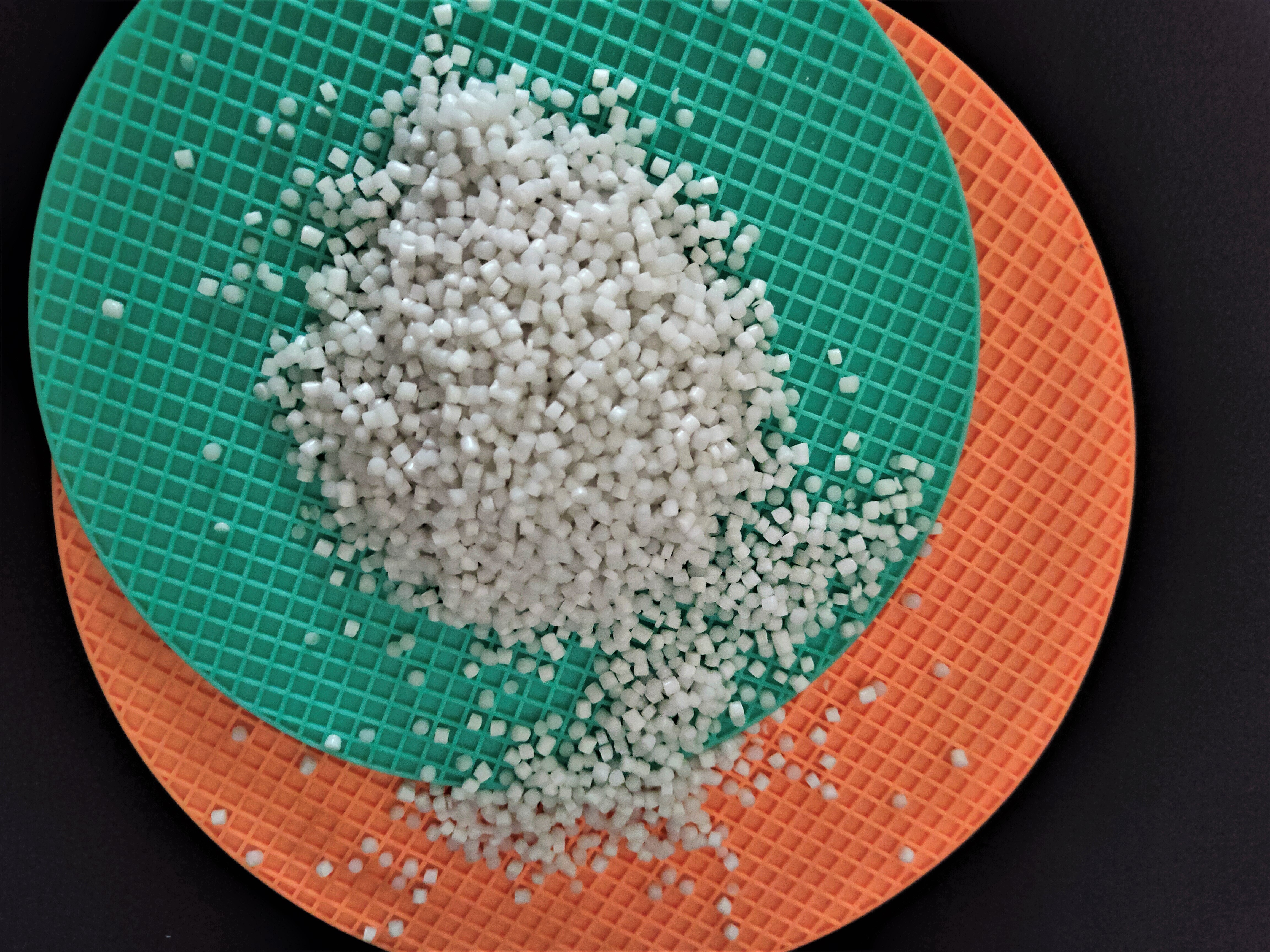

| Qhov tsos | pellet dawb los yog dawb tawm |

| Melting point (°C) | 45~65 |

| Viscosity (mPa.S) | 190 (100°C) |

| Kev Siv Tshuaj%(W/W) | 1 ~ 2.5% |

| Muaj peev xwm tiv taus nag los nag | Kub ntawm 100 ℃ rau 48 teev |

| Kub ntawm kev lwj (°C) | ≥300 |

Cov txiaj ntsig ntawm WPC lubricant additives

1. Txhim kho kev ua tiav, txo cov extruder torque, txhim kho cov khoom sib cais;

2. Cov roj nplua nyeem sab hauv thiab sab nraud rau WPC, txo kev siv hluav taws xob thiab ua kom muaj txiaj ntsig zoo dua;

3. Zoo sib xws nrog hmoov ntoo, tsis cuam tshuam rau cov zog ntawm cov molecules ntawm cov yas ntoo sib xyaw thiab tswj cov khoom siv kho tshuab ntawm lub substrate nws tus kheej;

4. Txo cov khoom sib xws, txo cov khoom tsis zoo, txhim kho cov tsos ntawm cov khoom yas ntoo;

5. Tsis muaj nag lossis daus tom qab sim ua kom npau, ua kom du thiab ntev.

Yuav siv li cas

Cov qib ntxiv ntawm 1 ~ 2.5% yog qhov pom zoo. Nws tuaj yeem siv rau hauv cov txheej txheem sib xyaw ua ke xws li Single / Twin ntsia hlau extruders, txhaj tshuaj molding thiab sab pub. Kev sib xyaw ua ke nrog cov polymer pellets tshiab yog qhov pom zoo.

Kev Thauj Mus Los & Kev Khaws Cia

Cov masterbatch no rau WPC ua tau tuaj yeem thauj mus los ua cov tshuaj tsis muaj kev phom sij. Nws raug pom zoo kom khaws cia rau hauv qhov chaw qhuav thiab txias nrog qhov kub cia hauv qab 40 ° C kom tsis txhob sib sau ua ke. Lub pob yuav tsum kaw zoo tom qab txhua zaus siv kom tiv thaiv cov khoom kom tsis txhob raug cuam tshuam los ntawm cov dej noo.

Pob & Lub neej txee

Lub ntim txheem yog lub hnab ntawv ua tes ua nrog PE sab hauv lub hnab nrog qhov hnyav tag nrho ntawm 25kg.Cov yam ntxwv qub tseem zoo li qub24lub hlis txij li hnub tsim khoom yog tias khaws cia rau hauv qhov chaw cia khoom pom zoo.

COV KHOOM SIV SILICONE DAWB THIAB COV QAUV Si-TPV NTAU TSHAJ 100 QIB

Hom qauv

$0

- 50+ xyoo

Qib Silicone Masterbatch

- 10+ xyoo

qib Silicone Hmoov

- 10+ xyoo

qib Anti-scratch Masterbatch

- 10+ xyoo

Qib Anti-abrasion Masterbatch

- 10+ xyoo

Qib Si-TPV

- 8+

qib Silicone Wax

-

Xov tooj

-

Email

-

Whatsapp

Whatsapp

-

Sab saum toj

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur