Cov khoom siv niaj hnub xws li khoom noj thiab khoom siv hauv tsev yog qhov tseem ceeb hauv tib neeg lub neej txhua hnub. Raws li lub neej niaj hnub txuas ntxiv mus sai sai, ntau yam khoom noj ntim thiab cov khoom siv niaj hnub tau puv cov khw muag khoom loj thiab cov khw loj, ua rau nws yooj yim rau tib neeg yuav, khaws cia, thiab siv cov khoom no. Cov ntaub ntawv ntim khoom ua lub luag haujlwm tseem ceeb hauv qhov yooj yim no. Nrog rau kev txhim kho tas mus li ntawm kev lag luam ntim khoom, cov kab ntau lawm ntim khoom tsis siv neeg tau siv ntau dua hauv kev tsim khoom noj thiab cov khoom siv niaj hnub. Raws li qhov ceev thiab kev ua haujlwm tsis siv neeg ntawm cov tshuab ntim khoom txuas ntxiv mus, cov teeb meem zoo kuj tau dhau los ua qhov tseem ceeb. Cov teeb meem xws li zaj duab xis tawg, kev plam, kev cuam tshuam cov kab ntau lawm, thiab cov pob khoom xau tau dhau los ua ntau zaus, ua rau muaj kev poob loj rau ntau lub tuam txhab tsim khoom ntim khoom yooj ywm thiab cov tuam txhab luam ntawv. Qhov laj thawj tseem ceeb yog qhov tsis muaj peev xwm tswj tau qhov sib txhuam thiab cua sov ntawm cov zaj duab xis ntim khoom tsis siv neeg.

Tam sim no, cov yeeb yaj kiab ntim khoom tsis siv neeg hauv khw muaj cov qhov tsis zoo tseem ceeb hauv qab no:

- Cov txheej sab nraud ntawm cov zaj duab xis ntim khoom muaj qhov sib txhuam qis (COF), thaum cov txheej sab hauv muaj COF siab, ua rau muaj kev sib txhuam thaum lub sijhawm khiav zaj duab xis ntawm kab ntim khoom.

- Cov zaj duab xis ntim khoom ua tau zoo ntawm qhov kub qis tab sis ntsib teeb meem ntawm qhov kub siab dua thaum lub sijhawm ntim khoom tsis siv neeg.

- Qhov COF qis ntawm txheej sab hauv tiv thaiv qhov chaw zoo ntawm cov ntsiab lus hauv zaj duab xis ntim khoom, ua rau kev sib khi tsis ua haujlwm thaum daim kab xev kub nias rau ntawm cov ntsiab lus.

- Cov zaj duab xis ntim khoom ua haujlwm tau zoo ntawm qhov ceev qis tab sis muaj teeb meem tsis zoo ntawm kev kaw cua sov thiab kev xau thaum lub sijhawm ntim khoom nce ntxiv.

Koj puas nkag siab txog qhovCOFntawm cov yeeb yaj kiab ntim khoom tsis siv neegFeem ntaucov tshuaj tiv thaiv kev thaiv thiab kev plamthiab cov teeb meem

COF ntsuas cov yam ntxwv ntawm cov khoom ntim khoom uas swb. Qhov du ntawm zaj duab xis thiab COF tsim nyog yog qhov tseem ceeb rau cov txheej txheem ntim zaj duab xis, nrog rau cov khoom ntim khoom sib txawv muaj cov COF xav tau sib txawv. Hauv cov txheej txheem ntim khoom tiag tiag, kev sib txhuam tuaj yeem ua ob qho tib si tsav thiab lub zog tiv thaiv, uas yuav tsum tau tswj hwm COF kom zoo hauv qhov ntau thiab tsawg. Feem ntau, cov yeeb yaj kiab ntim khoom tsis siv neeg xav tau COF qis rau txheej sab hauv thiab COF nruab nrab rau txheej sab nraud. Yog tias txheej sab hauv COF qis dhau, nws yuav ua rau tsis ruaj khov thiab tsis sib xws thaum lub sijhawm tsim lub hnab. Ntawm qhov tod tes, yog tias txheej sab nraud COF siab dhau, nws tuaj yeem ua rau muaj kev tiv thaiv ntau dhau thaum lub sijhawm ntim khoom, ua rau cov khoom puas, thaum COF qis dhau tuaj yeem ua rau plam, ua rau taug qab thiab txiav tsis raug.

COF ntawm cov yeeb yaj kiab sib xyaw yog cuam tshuam los ntawm cov ntsiab lus ntawm cov tshuaj tiv thaiv kev thaiv thiab cov neeg sawv cev hauv txheej sab hauv, nrog rau zaj duab xis qhov tawv thiab du. Tam sim no, cov neeg sawv cev siv hauv cov txheej sab hauv feem ntau yog cov tshuaj fatty acid amide (xws li cov amide thawj, cov amide thib ob, thiab bisamides). Cov ntaub ntawv no tsis yaj tag nrho hauv cov polymers thiab feem ntau mus rau qhov chaw ntawm zaj duab xis, txo qhov kev sib txhuam ntawm qhov chaw. Txawm li cas los xij, kev tsiv teb tsaws chaw ntawm cov neeg sawv cev amide hauv cov yeeb yaj kiab polymer yog cuam tshuam los ntawm ntau yam, suav nrog kev sib sau ua ke ntawm cov neeg sawv cev, cov tuab ntawm zaj duab xis, hom resin, kev nruj ntawm winding, qhov chaw cia khoom, kev ua tiav, cov xwm txheej siv, thiab lwm yam khoom ntxiv, ua rau nws nyuaj rau kom ntseeg tau tias COF ruaj khov. Ntxiv mus, thaum muaj ntau cov polymers raug ua tiav ntawm qhov kub siab dua, qhov kev ruaj khov thermal oxidative ntawm cov neeg sawv cev ua rau muaj kev tseem ceeb ntxiv. Kev puas tsuaj ntawm oxidative tuaj yeem ua rau poob ntawm kev ua haujlwm ntawm cov neeg sawv cev, kev hloov pauv, thiab tsw.

Cov neeg sawv cev uas siv ntau tshaj plaws hauv polyolefins yog cov roj fatty acid amides ntev, los ntawm oleamide mus rau erucamide. Qhov ua tau zoo ntawm cov neeg sawv cev yog vim lawv muaj peev xwm los nag rau ntawm qhov chaw ntawm zaj duab xis tom qab extrusion. Cov neeg sawv cev sib txawv qhia txog qhov sib txawv ntawm cov nag thiab COF txo qis. Raws li cov neeg sawv cev amide yog cov neeg sawv cev qis-molecular-weight migratory slip, lawv txoj kev tsiv teb tsaws chaw hauv zaj duab xis yog cuam tshuam los ntawm ntau yam, ua rau COF tsis ruaj khov. Hauv cov txheej txheem lamination tsis muaj kuab paug, cov neeg sawv cev amide ntau dhau hauv zaj duab xis tuaj yeem ua rau muaj teeb meem kev ua haujlwm sealing kub, feem ntau hu ua "blocking." Lub tshuab cuam tshuam nrog kev tsiv teb tsaws chaw ntawm cov monomers isocyanate dawb hauv cov nplaum rau ntawm qhov chaw ntawm zaj duab xis, cuam tshuam nrog amide los tsim urea. Vim yog qhov siab melting ntawm urea, qhov no ua rau txo qis kev ua haujlwm sealing kub ntawm zaj duab xis laminated.

Nlub qe kev swb super uas tsis tsiv teb tsaws chaw&Tiv thaiv kev thaivtus neeg sawv cev

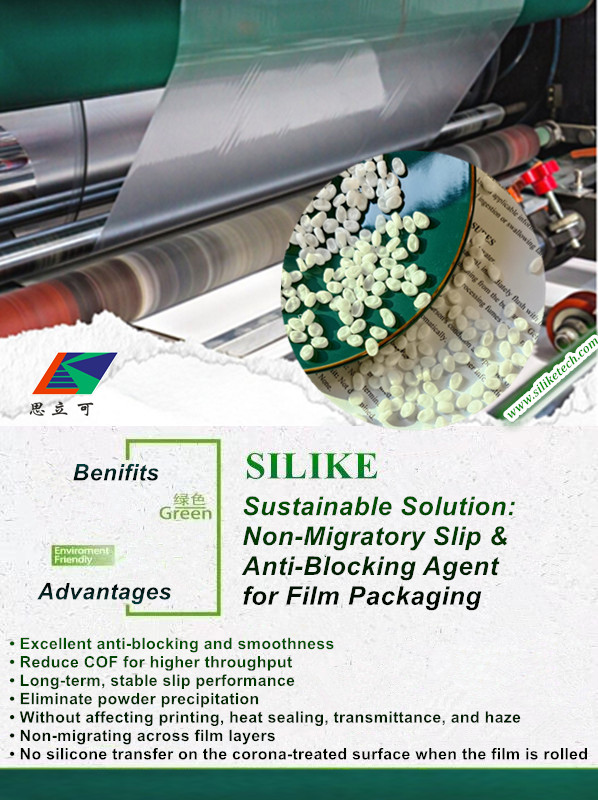

Txhawm rau daws cov teeb meem no, SILIKE tau tsim tawm Cov Khoom Siv Masterbatch Uas Tsis Ua Rau Nchuav Thiab Tiv Thaiv Kev Thaiv– ib feem ntawm SILIMER series. Cov khoom polysiloxane hloov kho no muaj cov pab pawg ua haujlwm organic. Lawv cov molecule suav nrog ob qho tib si polysiloxane saw ntu thiab cov saw carbon ntev nrog cov pab pawg nquag. Cov saw carbon ntev ntawm cov pab pawg ua haujlwm nquag tuaj yeem sib txuas nrog lub cev lossis tshuaj lom neeg nrog cov resin hauv paus, khi cov molecule thiab ua tiav kev tsiv teb tsaws chaw yooj yim yam tsis muaj nag. Cov saw polysiloxane saw ntu ntawm qhov chaw muab cov nyhuv du.

Tshwj xeeb,SILIMER 5065HByog tsim los rau cov yeeb yaj kiab CPP, thiabSILIMER 5064MB1Haum rau cov yeeb yaj kiab PE-blown thiab cov hnab ntim khoom sib xyaw. Cov txiaj ntsig ntawm cov khoom no suav nrog:

- SILIMER 5065HBthiabSILIMER 5064MB1muab kev tiv thaiv zoo heev thiab kev du, ua rau COF qis dua.

- SILIMER 5065HBthiabSILIMER 5064MB1muab kev ua tau zoo ruaj khov thiab mus tas li dhau sijhawm thiab nyob rau hauv qhov kub siab, tsis cuam tshuam rau kev luam ntawv, kev kaw cua sov, kev xa hluav taws xob, lossis pos huab.

- SILIMER 5065HBthiabSILIMER 5064MB1tshem tawm cov hmoov dawb uas poob rau hauv, kom ntseeg tau tias qhov kev ncaj ncees thiab kev zoo nkauj ntawm lub ntim khoom.

SILIKE's SILIMER cov tshuaj pleev xim tsis tawg pajmuab ib qho kev daws teeb meem zoo heev rau kev tswj COF ntawm cov yeeb yaj kiab ntim khoom tsis siv neeg, los ntawm Cast Polypropylene Films, PE-blown films mus rau ntau yam sib xyaw ua ke cov yeeb yaj kiab ua haujlwm. Los ntawm kev daws teeb meem kev tsiv teb tsaws chaw ntawm cov neeg sawv cev ib txwm muaj thiab txhim kho qhov kev ua tau zoo thiab tsos ntawm cov yeeb yaj kiab ntim khoom, SILIKE muab kev xaiv txhim khu kev qha rau cov chaw tsim khoom ntim khoom yooj ywm thiab cov tuam txhab luam ntawv.

Tiv tauj peb Xov tooj: +86-28-83625089 los yog xa email rau peb:amy.wang@silike.cn.

lub vas sab:www.siliketech.comkom paub ntau ntxiv.

Lub sijhawm tshaj tawm: Lub Xya Hli-09-2024