Nkag Siab Txog Qhov Teeb Meem: Hmoov thiab Paj hauv PE Zaj Duab Xis

Yog tias koj tau ntsib teeb meem hmoov thiab tawg paj hauv koj cov yeeb yaj kiab polyethylene (PE), koj tsis yog tib tug xwb. Qhov muaj cov hmoov dawb lossis cov quav ciab ntawm qhov chaw ntawm zaj duab xis yuav tsis tsuas yog cuam tshuam rau qhov zoo nkauj xwb tab sis kuj tseem muaj cov haujlwm tseem ceeb xws li qhov zoo ntawm kev luam ntawv thiab kev ntim khoom. Zoo hmoo, qhov teeb meem no - feem ntau yog los ntawm cov khoom ntxiv uas tawm hauv zaj duab xis - tuaj yeem tswj tau zoo nrog cov tswv yim zoo.

Vim li cas cov khoom ntxiv thiaj "tsiv chaw"? Cia peb tshawb nrhiav cov laj thawj

Kev hloov pauv ntawm cov khoom siv ntxiv rau kev sib txhuam feem ntau yog cuam tshuam los ntawm cov yam ntxwv ntawm qee cov ntaub ntawv es tsis yog koj cov txheej txheem ua. Cov roj nplua nyeem thiab cov neeg sawv cev xws li stearamide lossis erucamide, uas feem ntau ntxiv rau kom ua kom cov yeeb yaj kiab PE du, yuav tsim cov kev sib txuas tsis muaj zog nrog cov resin. Raws sijhawm thiab nrog kev hloov pauv ntawm qhov kub thiab txias, cov molecule me me no tuaj yeem txav mus rau saum npoo, ua rau pom cov txheej hmoov lossis cov quav ciab. Qhov teeb meem no tuaj yeem ua rau muaj kev cuam tshuam ntau dua hauv cov yeeb yaj kiab tuab dua, tshwj xeeb tshaj yog cov uas tuab dua 60μm, thiab tuaj yeem ua rau hnyav dua los ntawm qhov kub thiab txias lossis cov khoom siv seem.

Cov txiaj ntsig ntawm kev tsiv teb tsaws chaw ntxiv: Yuav tsum ceev faj txog dab tsi

Kev nkag siab txog tej yam uas yuav tshwm sim los ntawm kev tsiv teb tsaws chaw ntxiv tuaj yeem pab koj txo tau cov kev pheej hmoo kom zoo:

1. Kev Cuam Tshuam Kev Tsim Khoom: Cov hmoov av sib sau ua ke tuaj yeem ua rau muaj kev sib tsoo lossis tawg hauv cov tshuab ntim khoom tsis siv neeg, ua rau lub sijhawm tsis ua haujlwm kim heev.

2. Tej Yam Uas Yuav Tsum Tau Ua Thaum Luam Ntawv Thiab Lamination: Qhov chaw uas nplaum yuav ua rau cov kua mem lo rau tsis zoo, ua rau luam ntawv tsis zoo thiab tsis sib txuas zoo thaum lamination.

3. Kev Pheej Hmoo Txog Kev Ua Phem: Cov tshuaj ntxiv uas tau hloov mus rau lwm qhov chaw yuav ua rau cov khoom ntim tsis raug, ua rau cov neeg siv khoom tsis txaus siab thiab muaj peev xwm raug hu rov qab.

Cov Kev Dais Teeb Meem Rau PE Zaj Duab Xis Ntxiv Blooming

1. Kev Tsim Qauv thiab Kev Kho Kom Zoo:

Siv Cov Khoom Ntxiv Zoo Tshaj Plaws: Xav txog kev txo cov khoom ntxiv uas muaj qhov hnyav molecular qis thiab xaiv cov roj nplua nyeem uas muaj qhov hnyav molecular siab dua, xws li cov roj polyethylene uas muaj qhov ntom ntom siab, los txhim kho kev ruaj khov.

Sib xyaw kom sib npaug: Kev sib xyaw cov roj nplua nyeem nrog ntau yam ntsiab lus yaj tuaj yeem tsim kom muaj kev sib koom tes uas txo qis qhov kev pheej hmoo ntawm kev tsiv teb tsaws chaw ntau dhau.

Txhim kho cov xwm txheej ua haujlwm: Kho kom zoo dua qhov kub thiab txias ntawm kev ua haujlwm thiab qhov ceev ntawm kev rho tawm kom txo qhov kev sib txhuam thiab kev kub dhau uas tuaj yeem ua rau muaj kev hloov pauv ntxiv.

2. Txhim Kho Kev Tswj Xyuas Khoom Siv Raw:

Xyuas kom tseeb tias koj tau txais cov ntaub ntawv masterbatch los ntawm cov neeg muag khoom muaj npe nrov, vim tias cov ntaub ntawv tsis zoo yuav muaj cov khoom tsis huv me me uas ua rau muaj teeb meem hmoov.

3. Tshawb Nrhiav Cov Tshuaj Pleev Uas Muaj Kev Ua Haujlwm Zoo:

Yog tias yog ib txwm muajcov neeg sawv cev plamua rau muaj teeb meem uas tseem niaj hnub tshwm sim, tej zaum nws yog lub sijhawm los siv cov kev daws teeb meem siab dua.Cov neeg sawv cev ua los ntawm SILIKE's copolymer siloxanetau tsim los rau kev ruaj khov zoo tshaj plaws thiab sib xws nrog PE resins.

Vim Li Cas Thiaj XaivSILIKE's copolymer siloxane-based s super slip thiab anti-blocking Additives?

1. Kev nplua zoo tshaj plaws thiab tiv thaiv kev thaiv: Cov yas zaj duab xis no ua rau cov yas nplaum tsis lo thaum lub sijhawm ua haujlwm thaum tseem tswj tau qhov meej meej zoo heev.

2. Kev Ruaj Ntseg Kub: Nws cov qauv copolymer tshwj xeeb ua kom muaj kev ua tau zoo txawm tias nyob rau hauv qhov chaw kub siab.

3. Txo Qhov Kev Pheej Hmoo ntawm Hmoov: Kev sib raug zoo nrog PE pab txo qhov kev pheej hmoo ntawm kev tsiv teb tsaws chaw thiab hmoov av tau zoo.

4. Kev Ua Haujlwm Yooj Yim: Tus Neeg Sawv Cev Uas Tsis Yog Nag Los Ua Si Masterbatch txhawb nqa kev luam ntawv du, lamination, thiab cov txheej txheem kaw.

5. Kev Ua Haujlwm Zoo Dua: Cov khoom siv lubricating ua rau kev ua haujlwm zoo dua, txo cov khoom siv hnav, thiab txhawb nqa tag nrho cov khoom siv.

Ib Lus Cim Txog Kev Siv: Ua ntej hloov mus rau cov khoom ntxiv tshiab, nws yog ib qho zoo rau kev sim ua raws li koj cov xwm txheej ua haujlwm tshwj xeeb. Tiv tauj SILIKE kom tau txais cov qauv dawb ntawm SILIKE. super slip thiab anti-blocking SILIMER5064MBkom paub txog cov txiaj ntsig ntawm tes.

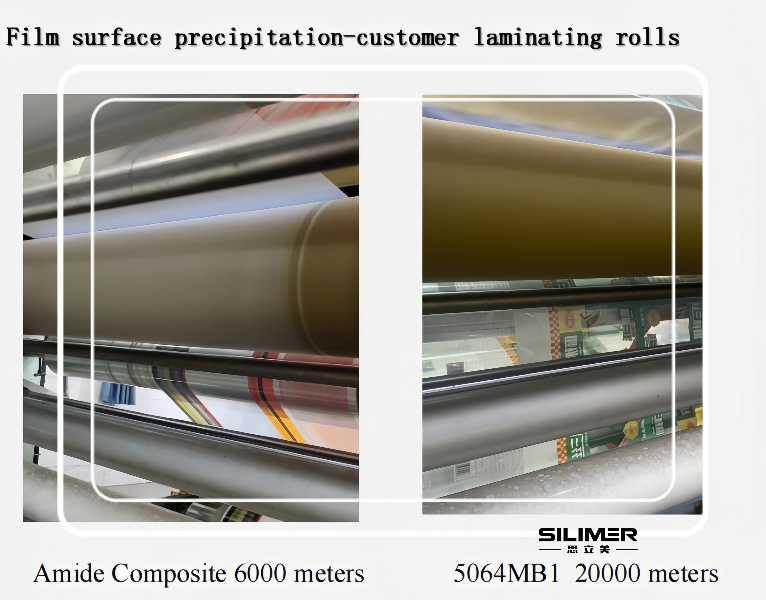

Los ntawm kev daws teeb meem hmoov ua ntej los ntawm kev hloov kho cov qauv tsim, kev tswj xyuas cov khoom siv raw kom zoo dua, thiab kev siv cov kev ua tau zoo,cov tshuaj ntxiv uas tsis txav mus los uas ua rau cov khoom plam zoo dua—xws li SILIKE Silicone Slip Masterbatch SILIMER 5064MB1 rau cov yeeb yaj kiab PE lossis tus neeg sawv cev tsis tawg paj SILIMER 5064MB4 rau cov yeeb yaj kiab polyethylene—koj tuaj yeem txhim kho qhov zoo thiab kev ua haujlwm ntawm koj cov txheej txheem PE zaj duab xis.

Txais yuav cov kev daws teeb meem no kom ua tiav kev tsim khoom du thiab tshawb nrhiav SILIKE txoj kev tsim kho tshiabcov khoom siv polyethylene zoo tshaj plawso hloov pauv koj cov txheej txheem. Ua ib lub chaw tsim khoom ntawm cov masterbatches uas tiv thaiv kev plam thiab thaiv kev thaiv, SILIKE muab kev ua tau zoo tshaj plaws.

Lub sijhawm tshaj tawm: Plaub Hlis-03-2025