Nyob rau lub caij nyoog uas cov qauv kev nyab xeeb thiab kev cai lij choj yog qhov tseem ceeb, kev tsim cov ntaub ntawv uas tiv taus hluav taws tau dhau los ua ib qho tseem ceeb ntawm ntau yam kev lag luam. Ntawm cov kev tsim kho tshiab no, cov tshuaj masterbatch uas tiv taus hluav taws tau tshwm sim los ua ib qho kev daws teeb meem zoo los txhim kho kev tiv thaiv hluav taws ntawm cov polymers.

Nkag Siab Txog Cov Tshuaj Masterbatch Uas Tiv Thaiv Tau Hluav Taws Yog Dab Tsi?

Cov tshuaj masterbatch uas tiv taus hluav taws yog cov tshuaj tshwj xeeb uas tsim los muab cov khoom tiv taus hluav taws rau cov polymers. Cov tshuaj no muaj cov roj hmab carrier, uas feem ntau yog tib yam polymer li cov khoom siv hauv paus, thiab cov tshuaj ntxiv uas tiv taus hluav taws. Cov roj hmab carrier ua haujlwm ua ib qho chaw nruab nrab rau kev faib cov neeg sawv cev tiv taus hluav taws thoob plaws hauv cov polymer matrix.

Cov Cheebtsam ntawm Cov Tshuaj Tiv Thaiv Hluav Taws Kub Masterbatch:

1. Cov Khoom Siv Resin:

Cov roj hmab nqa khoom yog cov khoom siv tseem ceeb ntawm cov masterbatch thiab raug xaiv raws li kev sib haum xeeb nrog cov polymer hauv paus. Cov roj hmab nqa khoom feem ntau suav nrog polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), thiab lwm yam thermoplastics. Kev xaiv cov roj hmab nqa khoom yog qhov tseem ceeb kom ntseeg tau tias muaj kev sib kis zoo thiab sib haum xeeb nrog cov polymer lub hom phiaj.

2. Cov Khoom Siv Tiv Thaiv Hluav Taws:

Cov tshuaj ntxiv uas tiv thaiv hluav taws yog cov khoom xyaw nquag uas ua rau tiv thaiv lossis ncua kev sib kis ntawm cov nplaim taws. Yeej, cov tshuaj tiv thaiv hluav taws tuaj yeem yog cov tshuaj ua xua lossis cov khoom ntxiv. Cov tshuaj ntxiv no tuaj yeem muab faib ua ntau pawg, suav nrog cov tshuaj halogenated, cov tshuaj phosphorus-based, thiab cov mineral fillers. Txhua pawg muaj nws txoj kev ua haujlwm tshwj xeeb hauv kev tiv thaiv cov txheej txheem combustion.

2.1 Cov Tshuaj Halogenated: Cov tshuaj brominated thiab chlorinated tso tawm cov halogen radicals thaum lub sijhawm combustion, uas cuam tshuam rau cov tshuaj combustion chain reaction.

2.2 Cov Tshuaj Phosphorus: Cov tshuaj no tso tawm phosphoric acid lossis polyphosphoric acid thaum lub sijhawm hlawv, tsim ib txheej tiv thaiv uas tiv thaiv cov nplaim taws.

2.3 Cov Khoom Siv Ua Kom Huv: Cov khoom siv ua kom huv xws li txhuas hydroxide thiab magnesium hydroxide tso cov pa dej tawm thaum raug cua sov, ua rau cov khoom txias thiab ua rau cov pa roj uas yooj yim hlawv.

3. Cov Khoom Siv Thiab Cov Khoom Siv Txhawb Nqa:

Cov khoom siv ntxiv xws li talc lossis calcium carbonate feem ntau raug ntxiv rau kom txhim kho cov khoom siv kho tshuab ntawm cov tshuaj masterbatch. Cov khoom txhawb nqa ua rau muaj kev ruaj khov, lub zog, thiab kev ruaj khov ntawm qhov ntev, pab txhawb rau kev ua tau zoo ntawm cov khoom siv.

4. Cov Khoom Ruaj Kho:

Cov tshuaj stabilizers tau muab tso rau hauv kom tiv thaiv kev puas tsuaj ntawm cov polymer matrix thaum lub sijhawm ua thiab siv. Piv txwv li, cov tshuaj antioxidants thiab UV stabilizers pab tswj cov khoom kom ruaj khov thaum raug rau cov yam ntxwv ib puag ncig.

5. Cov xim thiab cov xim:

Nyob ntawm seb siv li cas, cov xim thiab cov pigments raug ntxiv rau kom muab cov xim tshwj xeeb rau cov masterbatch compound. Cov khoom no kuj tseem tuaj yeem cuam tshuam rau cov khoom zoo nkauj ntawm cov khoom.

6. Cov Khoom Sib Xws:

Yog tias cov nplaim taws thiab cov polymer matrix tsis sib haum, cov compatibilizers raug siv. Cov neeg sawv cev no txhim kho kev sib cuam tshuam ntawm cov khoom, txhawb kev sib kis zoo dua thiab kev ua tau zoo tag nrho.

7. Cov Tshuaj Tua Pa Luam Yeeb:

Cov tshuaj tua pa luam yeeb, xws li zinc borate lossis molybdenum compounds, qee zaum suav nrog los txo qhov kev tsim cov pa luam yeeb thaum lub sijhawm hlawv, uas yog qhov tseem ceeb hauv kev siv hluav taws.

8. Cov Khoom Siv Ntxiv Rau Kev Ua:

Cov khoom siv ua haujlwm xws li cov roj nplua nyeem thiabcov neeg sawv cev dispersingpab txhawb cov txheej txheem tsim khoom. Cov tshuaj ntxiv no ua kom muaj kev ua tiav zoo, tiv thaiv kev sib sau ua ke, thiab pab ua kom cov tshuaj tiv thaiv hluav taws sib xyaw ua ke.

Cov saum toj no yog cov khoom sib xyaw ntawm cov tshuaj masterbatch uas tiv taus hluav taws, thaum xyuas kom meej tias cov tshuaj tiv taus hluav taws sib npaug hauv cov polymer matrix yog qhov tseem ceeb ntawm lawv cov txiaj ntsig. Kev tsis sib xyaw txaus tuaj yeem ua rau kev tiv thaiv tsis sib npaug, cov khoom siv puas tsuaj, thiab txo qis kev nyab xeeb hluav taws.

Yog li, cov tshuaj masterbatch uas tiv taus hluav taws feem ntau xav taucov tshuaj dispersantslos daws cov teeb meem cuam tshuam nrog kev sib kis ntawm cov neeg sawv cev nplaim taws hauv cov polymer matrix.

Tshwj xeeb tshaj yog nyob rau hauv lub ntiaj teb dynamic ntawm polymer science, qhov kev thov rau cov ntaub ntawv Flame Retardant siab heev nrog cov khoom ua tau zoo tshaj plaws tau txhawb nqa kev tsim kho tshiab hauv cov khoom ntxiv thiab cov khoom hloov kho. Ntawm cov kev daws teeb meem tshiab,cov tshuaj hyperdispersantstau tshwm sim ua cov neeg ua si tseem ceeb, daws cov teeb meem ntawm kev ua tiav qhov kev sib kis zoo tshaj plaws hauv Flame Retardant Masterbatch compound formulations.

As cov tshuaj hyperdispersantsdaws qhov teeb meem no los ntawm kev txhawb kom muaj kev faib cov tshuaj tua hluav taws kom sib npaug thiab sib npaug thoob plaws hauv cov tshuaj masterbatch.

Nkag mus rau Hyperdispersant SILIKE SILIMER 6150—ib chav kawm ntawm cov khoom ntxiv uas tab tom hloov kho qhov xwm txheej ntawm cov qauv tiv thaiv hluav taws!

SILIKE SILIMER 6150, tau tsim los ua kom tau raws li kev lag luam polymer cov kev xav tau sib txawv, Nws yog ib qho silicone wax hloov kho. Raws li ib qhocov tshuaj hyperdispersant zoo, muab kev daws teeb meem rau cov teeb meem cuam tshuam nrog kev ua tiav qhov kev faib tawm zoo tshaj plaws thiab, yog li ntawd, kev nyab xeeb hluav taws zoo tshaj plaws.

SILIKE SILIMER 6150 raug pom zoo raukev sib cais ntawm cov organic thiab inorganic pigments thiab fillers, cov tshuaj tiv thaiv hluav taws hauv thermoplastic masterbatch, TPE, TPU, lwm yam thermoplastic elastomers, thiab cov ntawv thov sib xyaw. Nws tuaj yeem siv rau hauv ntau yam thermoplastic polymers suav nrog polyethylene, polypropylene, polystyrene, ABS, thiab PVC.

SILIKE SILIMER 6150, Cov txiaj ntsig tseem ceeb ntawm cov tshuaj tua hluav taws

1. Txhim kho cov nplaim taws retardant dispersion

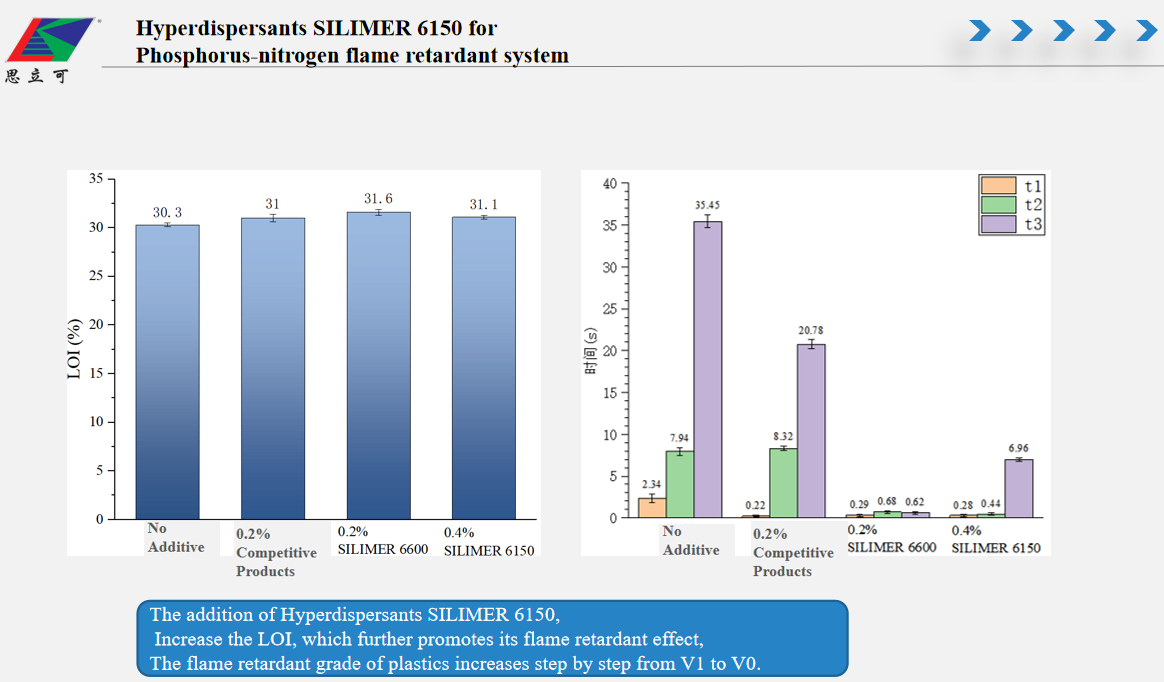

1) SILIKE SILIMER 6150 siv tau ua ke nrog cov phosphorus-nitrogen flame-retardant masterbatch, ua kom zoo dua qhov cuam tshuam ntawm cov nplaim taws retardant, Ua kom LOI nce ntxiv, cov nplaim taws retardant g.rade ntawm cov yas nce ntxiv los ntawm V1 txog V0.

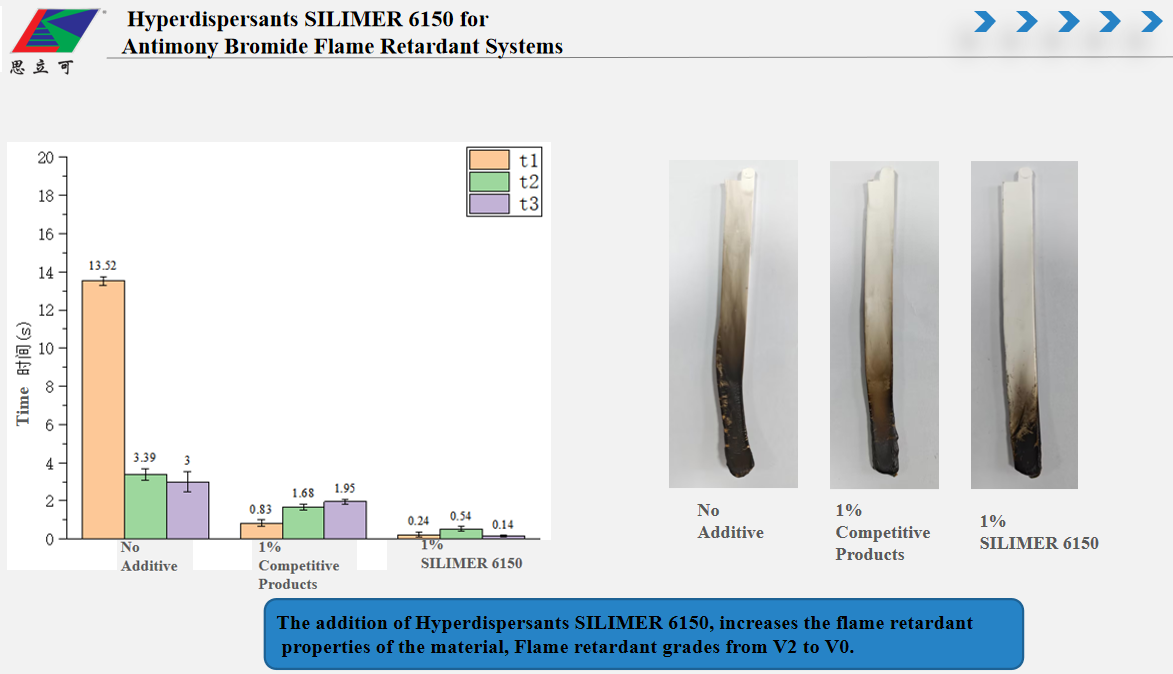

2) SILIKE SILIMER 6150 nrog rau muaj kev sib txuas zoo ntawm cov nplaim taws nrog Antimony Bromide Flame Retardant Systems, Flame retardant qib los ntawm V2 txog V0.

2. Txhim kho qhov ci ntsa iab thiab qhov du ntawm cov khoom (qis dua COF)

3. Txhim kho cov nqi ntws thiab kev sib kis ntawm cov khoom sau, kev tso tawm pwm zoo dua thiab kev ua haujlwm zoo dua

4. Xim zoo dua qub, tsis muaj kev cuam tshuam tsis zoo rau cov khoom siv kho tshuab.

Tiv tauj SILIKE kom pom tias SILIMER 6150 Hyperdispersant tuaj yeem pab cov neeg tsim cov tshuaj tiv thaiv hluav taws xob thiab cov thermoplastics li cas!

Lub sijhawm tshaj tawm: Lub Kaum Hli-23-2023