Cov Tshuaj Ntxiv Polymer (PPA) yog ib lo lus dav dav rau ntau hom khoom siv los txhim kho cov khoom ua thiab kev tuav ntawm cov polymers, feem ntau yog nyob rau hauv lub xeev molten ntawm cov polymer matrix ua lub luag haujlwm. Fluoropolymers thiab silicone resin polymer processing aids feem ntau yog siv rau hauv polyolefin polymers.

PPA siv tau rau cov ntaub ntawv xws li LLDPE, LDPE, HDPE, MDPE, PP, thermoplastic elastomers, PS, nylon, acrylic resins, PVC thiab lwm yam. Cov teb ntawm daim ntawv thov tuaj yeem yog blown zaj duab xis, cam khwb cia extrusion, hlau thiab cable, yeeb nkab thiab daim ntawv extrusion, masterbatch ua, hollow blow molding, thiab lwm yam.

Lub luag haujlwm tseem ceeb ntawm Polymer Processing Aid (PPA) hauv kev tsim thiab ua cov hlau thiab cable yog los txhim kho kev ua haujlwm ntawm cov polymer thiab cov khoom zoo. Cov hauv qab no yog qee qhov laj thawj tseem ceeb rau kev ntxiv PPA:

1. Txo qhov yaj viscosityPPA tuaj yeem txo qhov viscosity ntawm cov polymers, ua rau lawv yooj yim dua thaum lub sijhawm ua thiab txhim kho qhov ceev thiab kev tsim khoom extrusion.

2. Kev Zoo Nkauj ntawm KhoomPPA tuaj yeem txhim kho qhov ci ntsa iab thiab qhov tiaj tus ntawm cov xov hlau thiab cov khoom siv cable, txo qhov tsis zoo thiab qhov tsis zoo ntawm cov tsos, thiab txhim kho qhov zoo nkauj thiab tus nqi ntawm cov khoom.

3. Txo kev siv hluav taws xobVim tias PPA txo qhov viscosity ntawm cov polymer yaj, qhov kub thiab txias qis dua, thiab kev ntxhov siab yuav tsum tau ua thaum lub sijhawm extrusion, yog li txo kev siv zog thiab cov nqi.

4. Kev ruaj khov ntawm extrusion zoo dua: Qhov ntxiv ntawm PPA ua rau cov polymer ntws thiab yaj ruaj khov dua, txo qhov sib txawv ntawm kev rho tawm thiab kev puas tsuaj thaum lub sijhawm rho tawm, ua rau cov khoom ruaj khov dua ntawm qhov loj me thiab zoo.

Feem ntau, kev ntxiv cov khoom siv polymer ua PPA tuaj yeem txhim kho kev tsim khoom thiab kev ua haujlwm ntawm cov hlau thiab cable, thiab txhim kho cov khoom zoo thiab kev ua haujlwm zoo. Tab sis nrog rau kev txwv tsis pub siv fluoride, kev nrhiav lwm txoj hauv kev rau fluorinated PPA tau dhau los ua qhov kev sib tw tshiab.

Txhawm rau daws qhov teeb meem no, SILIKE tau tsim ib qhoLwm txoj hauv kev uas tsis muaj PTFErau Fluorine-based PPA ——ib qho tshuaj ntxiv rau kev ua cov polymer uas tsis muaj PFAS (PPA)Qhov noPPA MB uas tsis muaj fluorine, Cov khoom ntxiv uas tsis muaj PTFEyog ib qho organically hloov kho polysiloxane masterbatch uas siv cov nyhuv zoo heev ntawm polysiloxanes thiab polarity ntawm cov pab pawg hloov kho kom migrate thiab ua haujlwm rau cov khoom siv ua haujlwm thaum lub sijhawm ua haujlwm.

Cov khoom siv ua cov polymer uas tsis muaj PFAS (PPA)——pab txhawb kev tsim cov hlau thiab cov cable kom ua haujlwm tau zoo dua >>

SILIKE tsim cov PPA uas tsis muaj fluorine ua qhov hloov pauv zoo meej rau cov khoom siv ua cov khoom siv PPA uas muaj fluorinated, ib qho ntxiv me me ntawmSILIKE SILIMER-5090 Cov tshuaj ntxiv uas tsis yog fluoropolymertxhim kho kev ua haujlwm ntawm cov xov hlau thiab cov xov hlau. Txo qhov siab ntawm lub taub hau tuag, txhim kho kev ruaj khov ntawm kev rho tawm, txo qhov kev co ntawm kev rho tawm, tshem tawm kev sib sau ua ke ntawm lub taub hau tuag, txhim kho kev ua haujlwm zoo heev, txo qhov torque thiab txhim kho kev tsim khoom. Txhim kho qhov zoo ntawm qhov chaw thiab kev du ntawm cov khoom.

Cov khoom siv ua cov polymer uas tsis muaj SILIKE PFAS (PPA)muaj ntau yam kev siv rau cov cables, zaj duab xis, raj, masterbatches, cov nyom dag, thiab lwm yam.

Kev ua tau zoo li qub:

Kev ua haujlwm tau zoo dua

Kev ua kom lubrication zoo thiab kev sib kis

Kev ua haujlwm zoo dua

Tshem tawm cov kev tawg ntawm cov yaj

Txo cov kua qaub ncaug thiab cov pwm tsim tawm

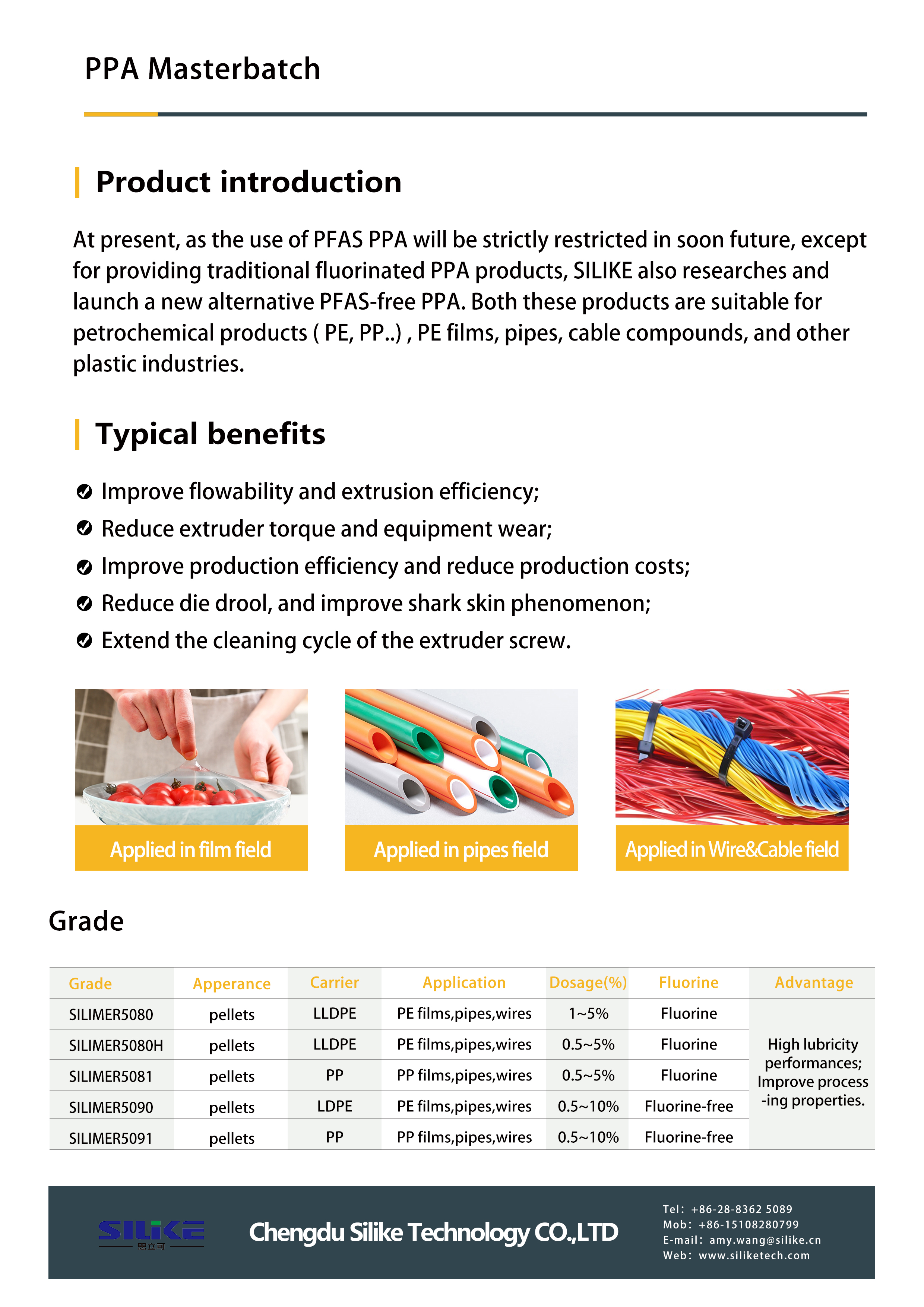

Hauv qab no yog cov qib pom zoo ntawmCov khoom siv ua cov khoom siv SILIKE PPA, koj tuaj yeem saib lawv. Yog tias koj muaj lus nug, thov tsis txhob yig tiv tauj kuv. SILIKE tos ntsoov yuav muab rau kojCov kev daws teeb meem rau fluorine-free PPA hauv cov ntawv thov hlau thiab cable.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-10-2023