PVC yog ib qho ntawm cov yas dav dav tshaj plaws hauv ntiaj teb uas muaj ntau yam kev siv. Nws yog siv dav hauv cov ntaub ntawv tsim kho, cov khoom lag luam, cov khoom siv niaj hnub, tawv hauv pem teb, vuas hauv pem teb, tawv cuav, yeeb nkab, xov hlau thiab cables, zaj duab xis ntim khoom, cov ntaub ntawv ua npuas ncauj, cov ntaub ntawv kaw, fibers thiab lwm yam. Txawm li cas los xij, cov teeb meem zoo ntawm cov khoom uas ntsib hauv kev tsim cov ntaub ntawv PVC tau ua rau muaj kev cuam tshuam rau kev tsim khoom thiab tus nqi ntawm cov lag luam.

Cov ntaub ntawv PVC muaj feem yuav muaj cov teeb meem thiab cov khoom tsis zoo thaum lub sijhawm ua vim yog qhov tsis zoo ntawm cov viscosity yaj siab, cov kua dej tsis zoo thiab cov thermal stability tsis zoo:

Cov ntaub ntawv PVC muaj teeb meem hauv kev ua tiav:

1. Nyuaj rau kev tswj qhov kub thiab txias ua haujlwmVim yog qhov tsis ruaj khov thermal ntawm PVC, nws yooj yim rau thermal degradation ntawm qhov kub siab, thiab xav tau kev tswj hwm qhov kub ua tiav kom tsis txhob muaj kev puas tsuaj ntawm cov khoom siv.

2. Kev ua kom tsis sib npaug: Cov viscosity yaj siab ua rau PVC tsis sib npaug, uas cuam tshuam rau kev ua haujlwm ntawm cov khoom siv thiab qhov zoo ntawm cov khoom.

3. kev siv khoom siv: PVC viscosity siab hauv cov txheej txheem ntawm cov khoom siv ua los ntawm kev hnav thiab tsim kua muag ntau dua, ua rau lub neej ua haujlwm luv dua.

4. Kev nyuaj siab hauv kev rhuav tshemVim yog qhov viscosity ntawm PVC, kev demoulding yuav nyuaj, ua rau cov khoom deformation lossis pwm puas tsuaj.

5. Kev ua haujlwm tsawg tsawgVim yog qhov tsis zoo ntawm cov kua dej, qhov ceev ntawm cov khoom siv PVC pwm qeeb thiab lub voj voog ntau lawm ntev, uas cuam tshuam rau kev ua haujlwm zoo.

Cov khoom PVC muaj qhov tsis zoo ntawm cov khoom:

1. Qhov chaw tsis du:Qhov tsis muaj kua dej ua rau muaj cov dej ntws, tsis sib npaug lossis tawv txiv kab ntxwv ntawm qhov chaw ntawm cov khoom.

2. Cov npuas sab hauv:qhov viscosity siab ntawm cov yaj yuav ua rau cov pa roj sab hauv nyuaj rau tso tawm, tsim cov npuas.

3. Lub zog tsis txaus ntawm cov khoom:Kev ua kom tsis sib npaug lossis kev ruaj khov thermal tsis zoo yuav ua rau lub zog thiab kev tawv tsis txaus ntawm cov khoom.

4. Xim tsis sib xws:kev ruaj khov thermal tsis zoo yuav ua rau muaj kev hloov pauv ntawm cov xim ntawm cov khoom thaum lub sijhawm ua haujlwm, cuam tshuam rau qhov zoo ntawm cov khoom.

5. Qhov ntev ntawm cov khoom tsis ruaj khov:Vim yog qhov tsis sib xws ntawm kev nthuav dav thermal thiab kev cog lus txias, cov khoom yuav muaj qhov sib txawv ntawm qhov ntev.

6. Kev tiv thaiv kev laus tsis zoo:kev ruaj khov thermal tsis zoo yuav ua rau cov khoom laus tau yooj yim thiab tawg yooj yim thaum siv ntev.

7. Khawb thiab rhuav tshem:Qhov dej ntws tsis zoo thiab lub zog yaj tsis txaus yuav ua rau qhov chaw ntawm cov khoom yooj yim khawb thiab tawg.

Yuav kom daws tau cov teeb meem ua cov khoom siv PVC thiab txo cov qhov tsis zoo ntawm cov khoom PVC, feem ntau yuav tsum hloov cov khoom siv PVC los ntawm kev ntxivcov khoom siv ua haujlwm, ua kom cov txheej txheem ua haujlwm zoo tshaj plaws, txhim kho kev tsim cov khoom siv, thiab lwm yam, txhawm rau txhim kho nws cov kev ua haujlwm thiab cov khoom zoo.

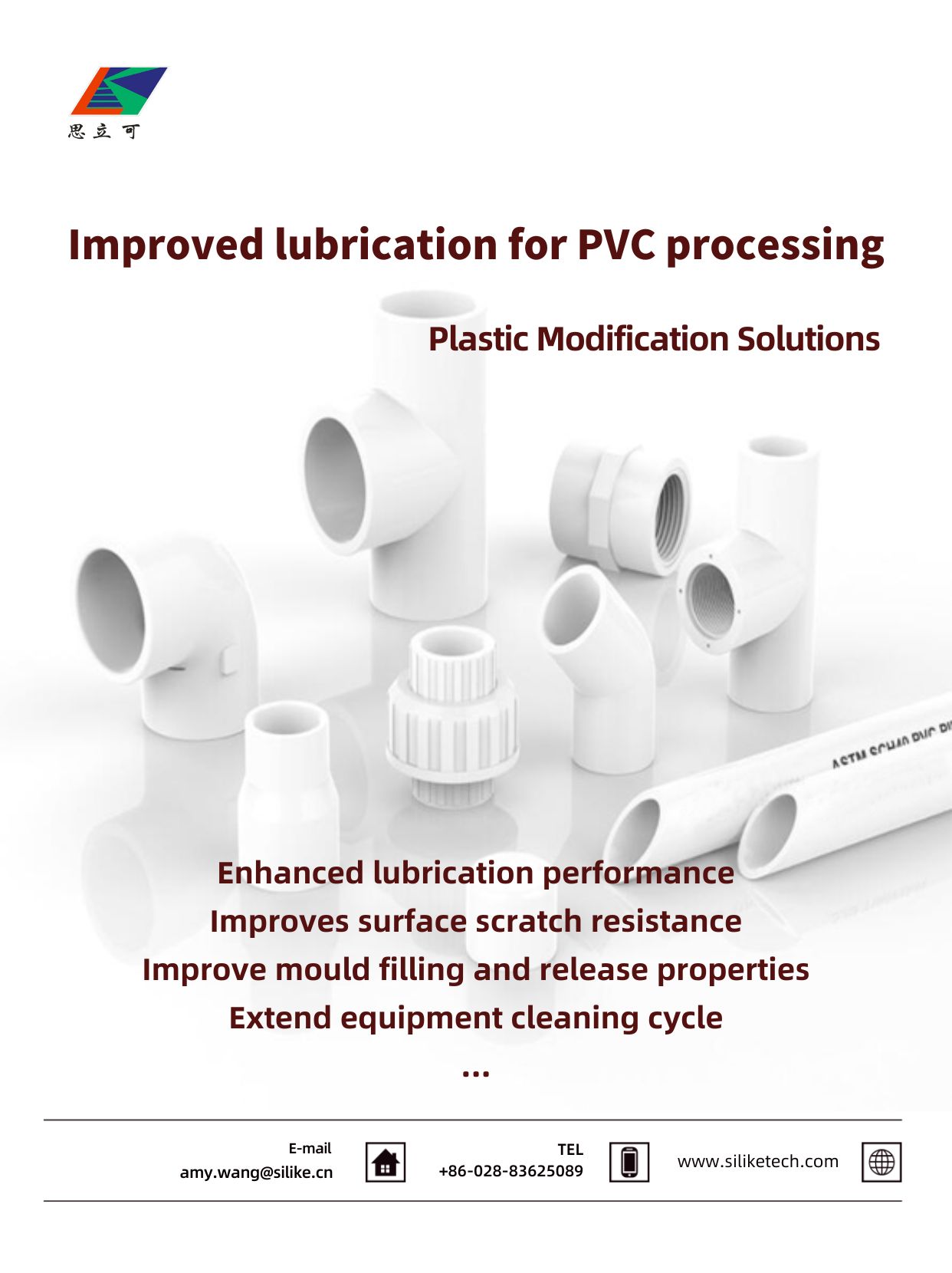

SILIKE SILIMER 5235,Cov kev daws teeb meem zoo los txhim kho kev ua haujlwm lubrication hauv PVC ua

SILIKE SILIMER 5235yog ib qho alkyl modified silicone additive. Nws yog siv rau hauv cov khoom yas super light xws li PVC, PC, PBT, PET, PC/ABS, thiab lwm yam. Tib lub sijhawm,SILIKE SILIMER 5235muaj cov qauv tshwj xeeb nrog kev sib raug zoo nrog cov matrix resin, tsis muaj nag lossis daus, tsis muaj kev cuam tshuam rau qhov tsos thiab kev kho qhov chaw ntawm cov khoom.

Cov txiaj ntsig ntawm daim ntawv thov ntawmSILIKE SILIMER 5235:

1. Kev ntxiv ntawmSILIKE SILIMER 5235nyob rau hauv qhov ntau thiab tsawg kom raug tuaj yeem txhim kho qhov khawb tsis kam thiab kev puas tsuaj ntawm cov khoom PVC.

2. Txo qhov coefficient ntawm kev sib txhuam ntawm qhov chaw, txhim kho qhov du ntawm qhov chaw;

3. Ua kom cov khoom muaj cov pwm zoo thiab lubricity, txhim kho kev ua haujlwm zoo.

4. NtxivSILIKE SILIMER 5235nyob rau hauv qhov ntau thiab tsawg kom raug tuaj yeem ua kom lub voj voog ntxuav ua haujlwm ntev dua thiab txhim kho kev ua haujlwm ntau lawm.

Koj puas muaj teeb meem los ntawm kev hloov kho yas, koj puas xav txhim kho qhov ua tiav thiab cov khoom nto ntawm cov ntaub ntawv PVC lossis lwm yam ntaub ntawv polyolefin, yog tias koj tab tom nrhiav cov khoom siv ua yas pheej yig, txais tos xaiv SILIKE.

Chengdu Silike Technology Co., Ltd, tus thawj coj hauv Suav teb Silicone Additive Supplier rau cov yas hloov kho, muab cov kev daws teeb meem tshiab los txhim kho kev ua tau zoo thiab kev ua haujlwm ntawm cov khoom siv yas. Txais tos tiv tauj peb, SILIKE yuav muab cov kev daws teeb meem ua cov yas zoo rau koj.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

lub vas sab:www.siliketech.comkom paub ntau ntxiv.

Lub sijhawm tshaj tawm: Lub Yim Hli-08-2024