Yuav ua li cas daws qhov teeb meem ntawm kev ua cov nplaim taws retardants?

Cov tshuaj tua hluav taws muaj kev lag luam loj heev thoob ntiaj teb thiab siv dav hauv kev lag luam xws li kev tsim kho, tsheb, khoom siv hluav taws xob, aerospace, thiab lwm yam. Raws li daim ntawv tshawb fawb kev lag luam, kev lag luam tshuaj tua hluav taws tau tswj hwm qhov kev loj hlob zoo hauv ob peb xyoos dhau los.

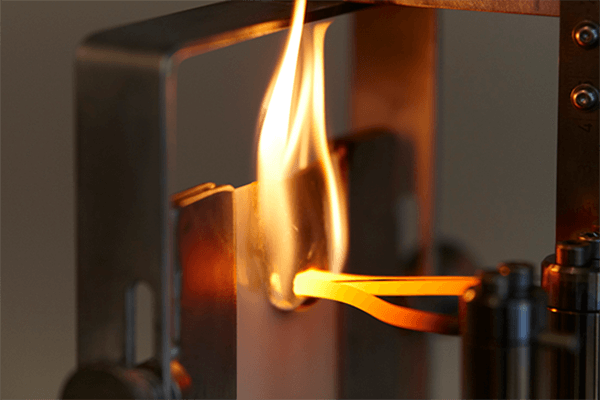

Txawm li cas los xij, nyob rau hauv cov txheej txheem tsim cov nplaim taws retardants, cov teeb meem ua tiav hauv qab no feem ntau ntsib:

Kev tawg tsis zoo: Cov tshuaj tua hluav taws feem ntau muaj nyob rau hauv daim ntawv ntawm cov khoom me me lossis hmoov thiab muaj qhov ceev thiab qhov hnyav tshwj xeeb, uas ua rau nws nyuaj rau kom tawg sib npaug hauv cov khoom siv thaum lub sijhawm ua tiav. Kev tawg tsis zoo yuav ua rau muaj kev faib tsis sib npaug ntawm cov tshuaj tua hluav taws hauv cov khoom siv, cuam tshuam rau cov nyhuv ntawm cov tshuaj tua hluav taws.

Kev ruaj khov thermal tsis zoo: Qee cov tshuaj tua hluav taws yuav lwj thaum kub siab lossis thaum raug rau qhov kub siab ntev, poob lawv cov nyhuv tua hluav taws thiab txawm tias tsim cov tshuaj lom. Yog li ntawd, nws yog qhov tsim nyog los tswj qhov kub thiab txias thiab lub sijhawm ua haujlwm thaum lub sijhawm ua haujlwm kom ntseeg tau tias qhov ruaj khov thermal ntawm cov tshuaj tua hluav taws.

Teeb meem sib xws: Tej zaum yuav muaj teeb meem sib xws ntawm cov nplaim taws retardant thiab cov khoom siv hauv paus, piv txwv li qhov sib raug zoo ntawm ob qho tsis muaj zog txaus los sib xyaw ua ke zoo. Qhov no yuav ua rau cov nplaim taws retardant tsis zoo thiab ua tsis tau zoo ntawm cov nplaim taws retardant.

Kev cuam tshuam rau cov khoom siv: Ntxiv ntau dhau ntawm cov tshuaj tua hluav taws yuav ua rau cov khoom siv kho tshuab thiab hluav taws xob ntawm cov khoom siv txo qis, thiab tseem ua rau cov khoom siv tawg thiab deformation. Yog li ntawd, nws yog qhov tsim nyog los tswj cov khoom ntxiv raws li cov khoom siv tshwj xeeb thiab cov yam ntxwv ntawm cov tshuaj tua hluav taws hauv cov txheej txheem.

Yuav kom kov yeej cov teeb meem machining no, cov kev ntsuas hauv qab no tuaj yeem ua tau:

Xaiv txoj kev ua haujlwm tsim nyog: Raws li cov khoom siv tshwj xeeb thiab cov khoom tiv thaiv hluav taws, xaiv txoj kev ua haujlwm tsim nyog, xws li extrusion, txhaj tshuaj molding, compression molding thiab lwm yam. Cov txheej txheem ua haujlwm sib txawv muaj cov teebmeem sib txawv rau kev tawg, kev sib raug zoo thiab kev ruaj khov thermal ntawm cov nplaim taws retardants.

Tswj tus nqi ntawm cov khoom ntxiv: Tswj tus nqi ntawm cov nplaim taws ntxiv kom tsim nyog, kom tsis txhob siv cov nplaim taws ntau dhau uas ua rau kev ua haujlwm ntawm cov khoom poob qis.

Ua kom zoo dua qhov kev sib kis ntawm cov nplaim taws retardants: Kev siv cov dispersants lossis cov hloov kho qhov chaw tuaj yeem txhim kho qhov kev sib kis ntawm cov nplaim taws retardants thiab ua rau lawv cov homogeneity hauv cov khoom siv.

Kev xaiv cov tshuaj tua hluav taws uas tsim nyog: Raws li cov kev cai thov tshwj xeeb, xaiv cov tshuaj tua hluav taws uas tsim nyog, xav txog cov yam ntxwv xws li lawv qhov kev ruaj khov thermal, kev sib raug zoo thiab kev sib kis.

SILIKE Hyperdispersants - Tsim tshwj xeeb rau kev tawg ntawm cov nplaim taws retardants. Cov khoom no yog tsim rau cov thermoplastic resins, TPE, TPU thiab lwm yam thermoplastic elastomers. Ntxiv rau cov nplaim taws retardants, cov khoom no kuj tsim rau masterbatches lossis cov ntaub ntawv pre-dispersed uas muaj concentrated heev.

- Kev ua haujlwm zoo lubricity

- Kev ua haujlwm zoo dua

- Kev sib raug zoo ntawm hmoov thiab substrate zoo dua

- Tsis muaj nag lossis daus, txhim kho qhov du ntawm qhov chaw

- Txhim kho kev sib kis ntawm cov hmoov hluav taws kub, kev ua kom tsis muaj hluav taws kub synergistic

Lub sijhawm tshaj tawm: Cuaj hlis-26-2023