Yuav ua li cas daws cov teeb meem ua haujlwm ntawm cov khoom siv cable uas tsis muaj pa luam yeeb tsawg?

LSZH sawv cev rau cov pa luam yeeb tsawg tsawg halogens, tsis muaj pa luam yeeb tsawg halogens, hom cable thiab hlau no tso tawm cov pa luam yeeb tsawg heev thiab tsis muaj cov tshuaj lom halogens thaum raug cua sov. Txawm li cas los xij, Txhawm rau kom ua tiav ob lub ntsiab lus tseem ceeb no, hauv kev tsim cov khoom siv cable tsis muaj pa luam yeeb tsawg halogens, Low-smoke zero halogens (LSZH) raug thauj khoom hnyav, uas kuj ua rau muaj cov khoom siv kho tshuab thiab ua haujlwm ncaj qha.

Qhov nyuaj hauv kev ua cov khoom siv uas tsis muaj pa luam yeeb tsawg halogen:

1. Cov mis mos ib txwm muaj, LLDPE/EVA/ATH cov ntsiab lus siab uas muaj LSZH polyolefin cable compounds muaj txog li 55-70% ATH/MDH, Raws li ntau tus txhuas hydroxide, magnesium hydroxide, thiab lwm yam nplaim taws retardants los koom nrog kev siv ntawm lub cev tsis zoo, kev sib txhuam cua sov thaum lub sijhawm ua haujlwm ua rau muaj kev nce ntxiv ntawm qhov kub uas ua rau kev puas tsuaj ntawm txhuas thiab magnesium hydroxide.

2. Kev ua haujlwm extrusion qis, txawm tias koj nce qhov ceev ntawm extrusion ntim tseem zoo li qub.

3. Kev sib raug zoo tsis zoo ntawm cov nplaim taws inorganic thiab cov khoom sau nrog polyolefins, kev tawg tsis zoo thaum lub sijhawm ua tiav, ua rau cov khoom siv kho tshuab txo qis.

4. Qhov chaw ntxhib thiab tsis ci ntsa iab thaum lub sijhawm extrusion vim yog qhov tsis sib xws ntawm cov tshuaj tua hluav taws inorganic hauv lub kaw lus.

5.Qhov polarity ntawm cov nplaim taws retardants thiab fillers ua rau cov yaj lo rau lub taub hau pwm, ncua qhov tso tawm ntawm cov khoom los ntawm pwm, lossis cov molecules me me hauv cov formulation precipitate tawm, ua rau muaj kev sib sau ua ke ntawm cov khoom ntawm qhov qhib pwm, yog li cuam tshuam rau qhov zoo ntawm cov cable.

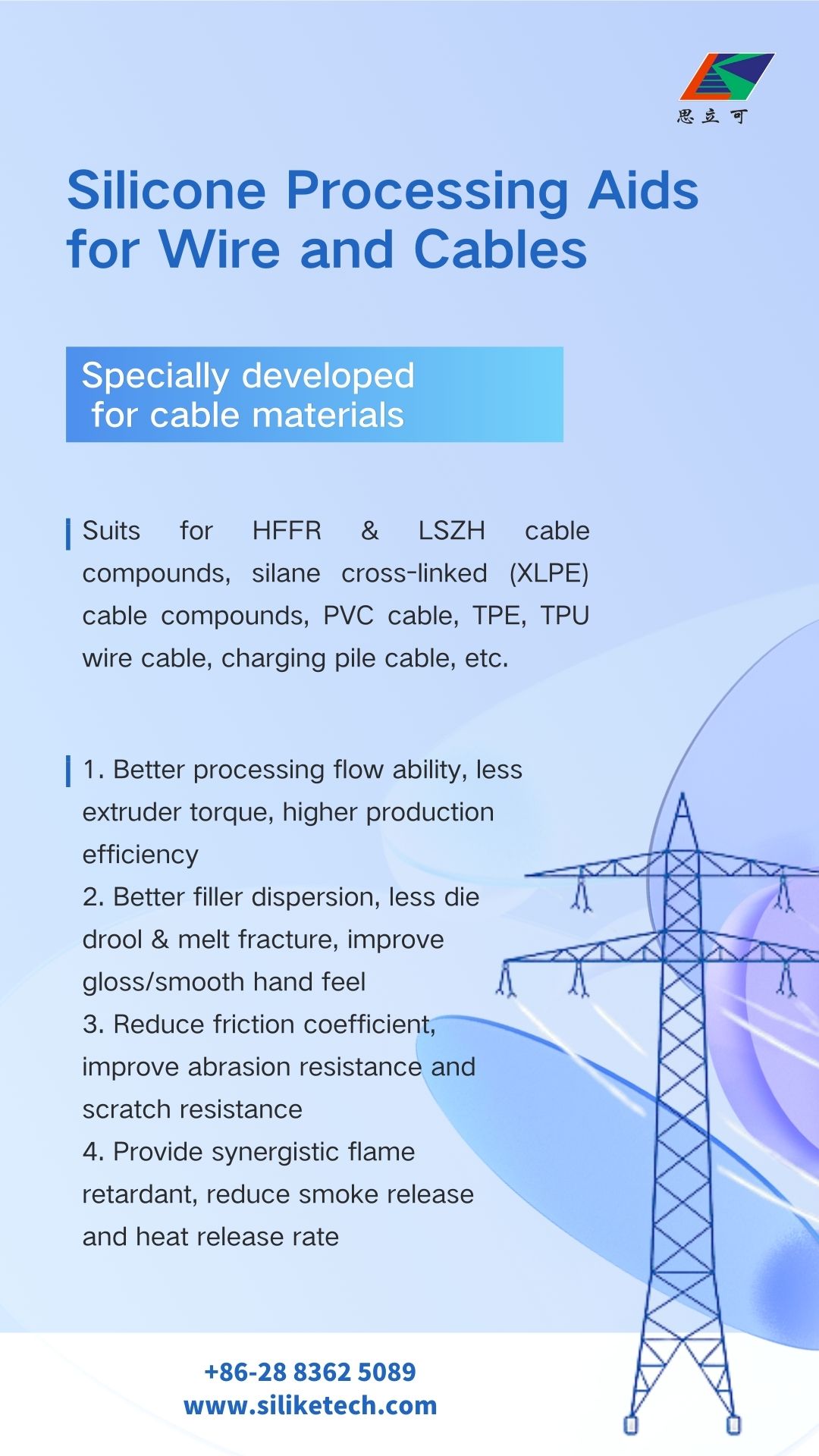

Raws li cov teeb meem saum toj no, SILIKE tau tsim ntau yamcov khoom siv siliconecov khoom lag luam tsim tshwj xeeb los daws cov teeb meem ntawm kev ua thiab qhov zoo ntawm cov khoom siv cable uas tsis muaj pa luam yeeb tsawg, cov hlau thiab cov khoom sib xyaw cable uas tsis muaj pa luam yeeb tsawg, lossis lwm cov khoom sib xyaw Polyolefin uas muaj cov zaub mov ntau rau cov hlau thiab cov ntawv thov cable, muab ntau yam kev daws teeb meem zoo rau cov teeb meem no.

Piv txwv li:Silicone Masterbatch (Siloxane Masterbatch) LYSI-401yog ib qho pelletized formulation nrog 50% ultra-high molecular weight siloxane polymer dispersed nyob rau hauv low-density polyethylene (LDPE). Nws yog dav siv ua ib qho kev ua haujlwm zoo hauv PE-compatible resin systems los txhim kho cov khoom ua haujlwm thiab hloov kho qhov zoo ntawm qhov chaw.

Ntxiv 0.5-2% ntawmSILIKE silicone masterbatch LYSI-401rau qhov hluav taws kub siab retardant filling system ntawm cov pa luam yeeb tsawg halogen dawb hlau & cable compounds lossis cov pa luam yeeb tsawg xoom halogens (LSZH) cable khoom ua rau cov hlau thiab cable ua kom muaj txiaj ntsig zoo tshaj plaws, tuaj yeem txhim kho cov txheej txheem ua haujlwm, txo qhov torque, ceev dua qhov chaw extrusion kab ceev yam tsis muaj kev tsiv teb tsaws chaw, txhim kho qhov zoo ntawm cov hlau thiab cable zoo li, (Cov coefficient qis dua ntawm kev sib txhuam, Txhim kho khawb thiab hnav tsis kam, zoo dua qhov chaw plam, thiab tes xis ...) yam tsis tau them tus nqi rau cov khoom siv tsis tsim nyog.

Feem ntau, rau Ordinarysilicone masterbatch, siloxane yog non-polar, thiab feem ntau ntawm cov pa roj carbon polymer solubility parameters ntawm qhov sib txawv yog loj heev, qhov ntxiv ntawm ntau tus neeg mob yuav ua rau cov txheej txheem ntawm cov ntsia hlau slippage, ntau lubrication, qhov chaw ntawm cov khoom delamination, cuam tshuam rau qhov chaw ntawm cov khoom ntawm cov khoom sib txuas ntawm cov khoom hauv lub substrate dispersed unevenly thiab lwm yam.

Thaum,SILIKE cov khoom siv silicone uas muaj cov molecular hnyav heevraug hloov kho los ntawm cov pab pawg tshwj xeeb, uas tuaj yeem xaiv thiab phim raws li qhov xav tau sib txawv ntawm cov khoom siv silicone hauv cov substrates sib txawv. Cov khoom no tuaj yeem ua lub luag haujlwm ntawm kev khi rau hauv cov substrate, yog li sib xws zoo dua nrog cov substrate, yooj yim dua dispersion, muaj zog dua kev sib txuas, thiab yog li muab cov substrate ua tau zoo dua. Thaum siv rau hauv LZSH thiab HFFR systems, nws tuaj yeem zam kev plam ntawm cov ntsia hlau thiab kuj tuaj yeem ua lub luag haujlwm tseem ceeb hauv kev txhim kho kev sib sau ua ke ntawm cov khoom hauv lub qhov ncauj pwm.

Lub sijhawm tshaj tawm: Cuaj hlis-07-2023