To taub Fiber thiab Monofilament:

Fiber thiab Monofilament yog ib txoj hlua lossis cov filaments ntawm ib yam khoom, feem ntau yog cov polymer hluavtaws xws li nylon, polyester, lossis polypropylene. Cov filaments no yog tus cwj pwm los ntawm lawv cov qauv ib-component, piv rau cov xov paj multifilament uas muaj ntau txoj hlua twisted lossis pawg ua ke.

Cov fiber thiab Monofilament pom cov ntawv thov hauv ntau yam lag luam, suav nrog cov ntaub, nuv ntses, thiab cov txheej txheem kev lag luam. Hauv cov ntaub, cov xov monofilament tuaj yeem siv rau cov ntawv thov xws li cov ntaub sheer, nets, thiab mesh. Hauv kev nuv ntses, cov kab monofilament feem ntau siv rau kev nuv ntses thiab kev nuv ntses lag luam vim lawv lub zog, kev ywj pheej, thiab kev tiv thaiv kev puas tsuaj. monofilament kuj tseem siv rau hauv cov ntsiab lus ntawm kev kho mob sutures, qhov twg ib txoj hlua ntawm cov khoom siv biocompatible siv rau kev xaws cov qhov txhab lossis phais mob.

Feem ntau, Hauv lub ntiaj teb dynamic ntawm polymer ua, qhov kev tshawb nrhiav rau kev ua haujlwm zoo thiab zoo hauv fiber lossis monofilament extrusion yog relentless. Cov chaw tsim khoom siv zog rau cov kev daws teeb meem tshiab los txhawb kev ua haujlwm ntau lawm, txiav downtime, thiab txo cov khib nyiab. cov txheej txheem tsim khoom tseem ceeb no hloov cov polymer resins mus rau hauv cov xov txuas ntxiv uas tau hloov kho rau ntau yam kev siv, xws li textiles thiab kev kho mob sutures rau cov khoom lag luam.

Cov teeb meem hauv FiberthiabKev rho tawm monofilament:

Kev sib sau ua ke ntawm cov pwm, kev ua qias tuaj ntawm cov ntaub thaiv, thiab kev tawg ntawm cov xov hlau ua rau muaj teeb meem rau cov chaw tsim khoom, cuam tshuam rau qhov zoo ntawm cov khoom kawg thiab ua rau lub sijhawm tsis ua haujlwm thiab cov nqi nce ntxiv. Cov tshuaj fluoropolymers ib txwm muaj thiab cov tshuaj PFAS uas muaj tau siv los uaCov khoom siv ua cov polymer zoo (PPAs), Tab sis, raws li cov cai tshiab hauv Tebchaws Europe thiab Tebchaws Meskas tsim cov kev txwv thiab txwv tsis pub siv cov fluoropolymers, thiab cov tshuaj PFAS, cov chaw tsim khoom nrhiav lwm txoj hauv kev uas ua raws li cov cai no yam tsis muaj kev cuam tshuam rau kev ua tau zoo.

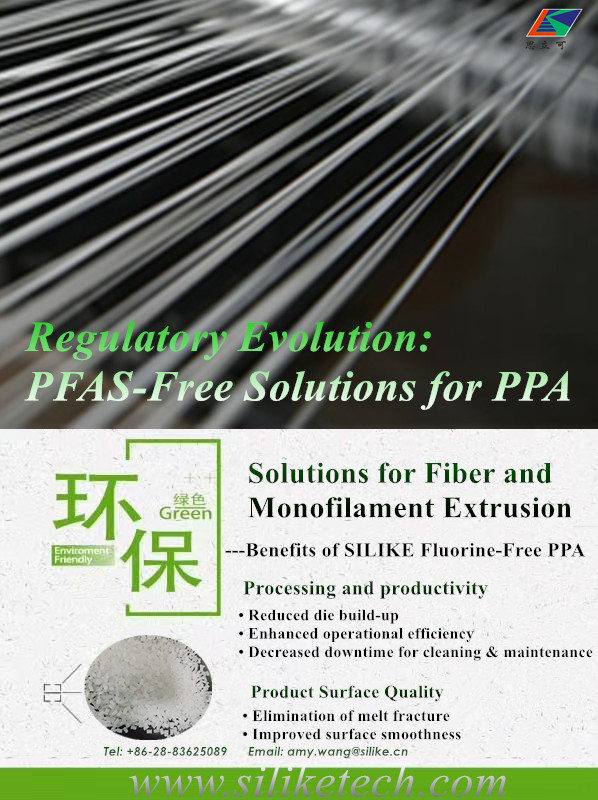

SILIKE's PFAS-Free PPAKev daws teeb meem:

SILIKE cov khoom siv ua cov khoom siv polymer uas tsis muaj PFAStshwm sim los ua ib qho kev daws teeb meem tshiab rau cov teeb meem uas ntsib.Cov Khoom Siv Ua Polymer Tsis Muaj Fluorine (PPA) SILIMER 5090ua raws li cov cai ntawm EU uas yuav los txog, tshem tawm cov kev txwv thiab kev txwv tsis pub siv cov tshuaj fluoropolymers thiab cov tshuaj PFAS uas muaj.

peb txoj kev daws teeb meem tshiab ua kom muaj kev tsim khoom polymer uas muaj lub luag haujlwm, muab qhov tseem ceeb rau kev ruaj khov yam tsis muaj kev cuam tshuam rau qhov zoo lossis kev ua haujlwm zoo.

Cov ntawv thov ib txwm muaj uas tau txais txiaj ntsig los ntawm kev siv suav nrog:

• Zaj duab xis uas cua thiab pov tseg

• Kev rho tawm zaj duab xis ntau txheej

• Kev rho tawm Cable & Yeeb Nkab

• Kev rho tawm fiber ntau thiab monofilament

• Kev ua cov roj av

• Daim ntawv extrusion

• Kev sib xyaw ua ke

Qhib Txoj Kev Mus Rau Qhov Zoo Tshaj Plaws Fiber thiab Monofilament Extrusion!

Hauv thaj chaw ntawm cov pwm nqaim thiab cov ntim ntau uas tsim cov fibers ultra-thin, cov pwm thiab cov ntxaij vab tshaus sib sau ua ke, cov pwm txuas, thiab cov xov tawg ua rau muaj kev cov nyom ua rau muaj kev pov tseg thiab lub sijhawm tsis ua haujlwm. Yuav daws cov teeb meem Fiber thiab Monofilament Extrusion li cas?

Qhib Kev Ua Haujlwm Zoo hauv Kev Tsim Khoom Fiber thiab Monofilament nrog SILIKE's PFAS-Free PPA!

1. Kev Txo Qhov Kev Sib Sau Ua Ke ntawm Cov Tuag thiab Cov Npoo Npog:Cov qauv tshiab ntawmSILIKE Cov Khoom Siv Ua Polymer Tsis Muaj Fluorine (PPA) SILIMER 5090ua kom txo tau qhov kev sib sau ua ke ntawm cov khoom tsis huv thiab cov polymer residues hauv cov pwm nqaim thiab cov pob screen. Qhov kev txo qis no ua kom cov txheej txheem extrusion du thiab tiv thaiv qhov xav tau kev ntxuav thiab kev saib xyuas ntau zaus.

2. Kev Tiv Thaiv Kev Txuas Tuag: Cov qauv tshwj xeeb ntawm SILIKE Cov Khoom Siv Ua Polymer Tsis Muaj Fluorine (PPA) SILIMER 5090pab tiv thaiv kom tsis txhob muaj lub pwm txhaws, uas yog ib qho teeb meem uas cuam tshuam kev ntws ntawm cov polymer los ntawm lub pwm. Qhov no ua rau muaj kev rho tawm zoo dua thiab cov khoom kawg zoo dua.

3. Kev Txo Qhov Kev Tawg Ntawm StrandLos ntawm kev txhim kho cov khoom siv polymer ntws,SILIKE Cov Khoom Siv Ua Polymer Tsis Muaj Fluorine (PPA) SILIMER 5090pab txo cov xov tawg thaum lub sijhawm extrusion. Qhov no tsis yog tsuas yog txhim kho kev ua haujlwm ntau lawm xwb tab sis kuj txo cov khib nyiab, ua rau cov chaw tsim khoom txuag tau nyiaj.

4. Kev Siv Nyiaj Tau Zoo thiab Kev Txo Lub Sijhawm Tsis Ua HaujlwmKev sib xyaw ua ke ntawm kev txo cov pwm thiab cov ntxaij vab tshaus, kev tiv thaiv kev txhaws ntawm cov pwm, thiab kev txo qis kev tawg ntawm cov xov hlau ua ke pab txhawb rau kev txuag nqi ntau thiab txo lub sijhawm tsis ua haujlwm. Cov chaw tsim khoom tuaj yeem ua tiav cov ntim ntau dua nrog kev ua haujlwm zoo dua.

Npaj txhij los txhim kho koj cov txheej txheem extrusion? Tshawb nrhiav lub peev xwm ntawmSILIKE cov khoom siv ua cov khoom siv polymer uas tsis muaj PFAS SILIMER 5090rau kev ua tau zoo tshaj plaws hauv kev tsim cov fiber thiab monofilament.

Tab sis qhov ntawd tsis yog txhua yam - Tshawb nrhiav cov ntawv thov tsis muaj ciam teb ntawmSILIKE Cov Khoom Siv Ua Polymer Tsis Muaj Fluorine (PPA) SILIMER 5090dhau ntawm Fiber thiab Monofilament Extrusion, Los ntawm Blown zaj duab xis, cast zaj duab xis, Cable, kav dej, Fiber, thiab Monofilament Extrusion, Sheet extrusion, Compounding rau petrochemicals, metallocene polypropylene, lossis metallocene PE.SILIKE cov khoom siv ua cov khoom siv polymer uas tsis muaj PFASyog koj tus yuam sij rau kev ua tau zoo tshaj plaws Kev Ua Raws Cai Sib Tw Nrog Kev Tsim Kho Tshiab, ua raws li cov cai ntawm EU uas yuav los txog, zam kev txwv thiab kev txwv tsis pub siv cov tshuaj fluoropolymers thiab cov tshuaj PFAS. Qhov kev daws teeb meem tshiab no ua kom muaj kev tsim cov polymer uas muaj lub luag haujlwm yam tsis muaj kev cuam tshuam rau qhov zoo lossis kev ua haujlwm, cog lus tias yuav muaj ntau yam txiaj ntsig zoo rau kev tsim khoom.

Txuas nrog SILIKE hnub no los txhim kho koj cov txheej txheem polymer, txhawb kev tsim khoom, thiab tsa cov khoom zoo!

Tel: +86-28-83625089 Email: amy.wang@silike.cn

Lub Vas Sab:www.siliketech.com

Lub sijhawm tshaj tawm: Lub Ib Hlis-10-2024