Kev Taw Qhia Txog Polyolefins thiab Zaj Duab Xis Extrusion

Polyolefins, ib hom khoom siv macromolecular uas ua los ntawm olefin monomers xws li ethylene thiab propylene, yog cov yas uas tsim thiab siv ntau tshaj plaws thoob ntiaj teb. Lawv qhov kev nthuav dav yog los ntawm kev sib xyaw ua ke ntawm cov khoom zoo, suav nrog tus nqi qis, kev ua haujlwm zoo heev, kev ruaj khov tshuaj zoo heev, thiab cov yam ntxwv lub cev uas hloov kho tau. Ntawm ntau yam kev siv polyolefins, cov khoom siv zaj duab xis tuav lub luag haujlwm tseem ceeb, ua haujlwm tseem ceeb hauv kev ntim khoom noj, kev ua liaj ua teb, kev ntim khoom lag luam, kev kho mob thiab cov khoom siv tu cev, thiab cov khoom siv niaj hnub. Cov polyolefin resins feem ntau siv rau kev tsim zaj duab xis suav nrog polyethylene (PE) - suav nrog Linear Low-Density Polyethylene (LLDPE), Low-Density Polyethylene (LDPE), thiab High-Density Polyethylene (HDPE) - thiab polypropylene (PP).

Kev tsim cov yeeb yaj kiab polyolefin feem ntau vam khom cov thev naus laus zis extrusion, nrog rau Blown Film Extrusion thiab Cast Film Extrusion yog ob qho txheej txheem tseem ceeb.

1. Cov txheej txheem cua tshuab zaj duab xis extrusion

Kev siv tshuab cua tshuab los ua cov zaj duab xis yog ib txoj kev siv ntau tshaj plaws los tsim cov zaj duab xis polyolefin. Lub hauv paus ntsiab lus tseem ceeb yog kev siv tshuab cua tshuab cov polymer uas yaj mus rau saum toj los ntawm lub pwm annular, tsim cov parison nyias-walled. Tom qab ntawd, cua compressed raug coj mus rau hauv sab hauv ntawm lub parison no, ua rau nws ua npuas nrog lub cheeb tsam loj dua li ntawm lub pwm. Thaum lub npuas nce mus, nws raug yuam kom txias thiab khov los ntawm lub nplhaib cua sab nraud. Lub npuas txias ces raug tsoo los ntawm ib pawg ntawm cov menyuam dov (feem ntau los ntawm lub thav duab uas tawg lossis A-frame) thiab tom qab ntawd rub los ntawm cov menyuam rub ua ntej raug qhwv rau ntawm lub yob. Cov txheej txheem cua tshuab feem ntau ua rau cov zaj duab xis nrog kev taw qhia biaxial, txhais tau tias lawv muaj kev sib npaug zoo ntawm cov khoom siv kho tshuab hauv ob qho tib si kev taw qhia tshuab (MD) thiab kev taw qhia transverse (TD), xws li lub zog tensile, kev tiv thaiv kua muag, thiab lub zog cuam tshuam. Cov tuab zaj duab xis thiab cov khoom siv kho tshuab tuaj yeem tswj tau los ntawm kev kho qhov piv ntawm lub npuas (BUR - piv ntawm lub cheeb tsam npuas rau lub cheeb tsam pwm) thiab qhov piv ntawm kev rub tawm (DDR - piv ntawm qhov ceev coj mus rau qhov ceev extrusion).

2. Txheej Txheem Extrusion Film Cast

Kev rho tawm zaj duab xis yog lwm txoj hauv kev tseem ceeb rau cov zaj duab xis polyolefin, tshwj xeeb tshaj yog rau kev tsim cov zaj duab xis uas xav tau cov khoom siv kho qhov muag zoo dua (piv txwv li, qhov meej siab, ci ntsa iab siab) thiab qhov tuab zoo sib xws. Hauv cov txheej txheem no, cov polymer molten raug rho tawm kab rov tav los ntawm lub tiaj tus, hom T-die, tsim cov ntaub ntawv molten sib xws. Cov ntaub ntawv no ces raug rub sai sai rau ntawm qhov chaw ntawm ib lossis ntau qhov ceev ceev, txias sab hauv. Cov yaj khov sai sai thaum kov qhov chaw txias. Cov zaj duab xis feem ntau muaj cov khoom siv kho qhov muag zoo heev, qhov xav mos, thiab kev kaw cua sov zoo. Kev tswj hwm qhov sib txawv ntawm daim di ncauj tuag, qhov kub ntawm cov ntaub ntawv txias, thiab qhov ceev ntawm kev sib hloov ua rau muaj kev tswj hwm qhov tuab ntawm zaj duab xis thiab qhov zoo ntawm qhov chaw.

Sab saum toj 6 Polyolefin zaj duab xis Extrusion kev sib tw

Txawm hais tias cov thev naus laus zis extrusion tau loj hlob tuaj lawm, cov tuam txhab tsim khoom feem ntau ntsib ntau yam teeb meem hauv kev tsim cov yeeb yaj kiab polyolefin, tshwj xeeb tshaj yog thaum siv zog rau cov zis siab, kev ua haujlwm zoo, cov ntsuas nyias dua, thiab thaum siv cov resins ua haujlwm siab tshiab. Cov teeb meem no tsis tsuas yog cuam tshuam rau kev ruaj khov ntawm kev tsim khoom xwb tab sis kuj cuam tshuam ncaj qha rau qhov zoo thiab tus nqi ntawm cov khoom kawg. Cov teeb meem tseem ceeb suav nrog:

1. Qhov tawg ntawm cov yas yaj (Sharkskin): Qhov no yog ib qho ntawm cov teeb meem feem ntau hauv kev rho tawm zaj duab xis polyolefin. Macroscopically, nws qhia tau tias yog cov ripples transverse lossis qhov chaw tsis sib xws ntawm zaj duab xis, lossis hauv cov xwm txheej hnyav, muaj kev cuam tshuam ntau dua. Qhov tawg ntawm cov yas yaj feem ntau tshwm sim thaum tus nqi shear ntawm cov polymer yaj tawm ntawm lub pwm tshaj qhov tseem ceeb, ua rau muaj kev sib txhuam ntawm cov phab ntsa pwm thiab cov yaj loj, lossis thaum qhov kev ntxhov siab ntawm qhov tawm ntawm lub pwm tshaj qhov muaj zog yaj. Qhov teeb meem no ua rau cov khoom siv kho qhov muag ntawm zaj duab xis (qhov tseeb, ci ntsa iab), qhov du ntawm qhov chaw, thiab tseem tuaj yeem ua rau nws cov khoom siv kho tshuab thiab cov khoom thaiv puas tsuaj.

2. Cov kua qaub ncaug / Cov Khoom Siv Ua Rau Tuag: Qhov no hais txog kev sib sau ua ke ntawm cov khoom polymer degradation, cov khoom me me uas muaj qhov hnyav molecular qis, cov khoom ntxiv uas tsis zoo (piv txwv li, cov xim, cov tshuaj tiv thaiv static, cov tshuaj slip), lossis cov gels los ntawm cov resin ntawm ntug ntawm cov pwm lossis hauv qhov pwm. Cov deposits no tuaj yeem detached thaum lub sijhawm tsim khoom, ua rau cov zaj duab xis ntawm qhov chaw thiab ua rau muaj qhov tsis zoo xws li gels, streaks, lossis khawb, yog li cuam tshuam rau cov khoom zoo li thiab zoo. Hauv cov xwm txheej hnyav, cov pwm sib sau ua ke tuaj yeem thaiv qhov tawm ntawm pwm, ua rau muaj kev hloov pauv ntawm qhov ntsuas, zaj duab xis rhuav tshem, thiab thaum kawg yuam kom cov kab ntau lawm kaw rau kev ntxuav pwm, ua rau muaj kev poob loj hauv kev ua haujlwm ntau lawm thiab cov khoom siv raw pov tseg.

3. Kev Siab Siab thiab Kev Hloov Pauv Siab ntawm Extrusion: Nyob rau hauv qee qhov xwm txheej, tshwj xeeb tshaj yog thaum ua cov resins uas muaj viscosity siab lossis siv cov qhov me me ntawm lub pwm, qhov siab hauv lub kaw lus extrusion (tshwj xeeb tshaj yog ntawm lub taub hau extruder thiab lub pwm) tuaj yeem siab dhau. Qhov siab siab tsis yog tsuas yog ua rau kev siv hluav taws xob ntau ntxiv xwb tab sis kuj ua rau muaj kev pheej hmoo rau lub neej ntev ntawm cov khoom siv (piv txwv li, ntsia hlau, lub thoob, lub pwm) thiab kev nyab xeeb. Ntxiv mus, qhov kev hloov pauv tsis ruaj khov ntawm qhov siab extrusion ncaj qha ua rau muaj kev hloov pauv ntawm cov zis yaj, ua rau cov zaj duab xis tuab tsis sib xws.

4. Kev Siv Tau Tsawg: Txhawm rau tiv thaiv lossis txo cov teeb meem xws li kev tawg ntawm cov yas thiab kev sib sau ua ke ntawm cov pwm, cov chaw tsim khoom feem ntau raug yuam kom txo qhov ceev ntawm lub extruder ntsia hlau, yog li txwv cov kab ntau lawm. Qhov no cuam tshuam ncaj qha rau kev ua haujlwm zoo ntawm kev tsim khoom thiab tus nqi tsim khoom ib chav ntawm cov khoom, ua rau nws nyuaj rau ua kom tau raws li kev xav tau ntawm kev ua lag luam rau cov yeeb yaj kiab loj, pheej yig.

5. Qhov nyuaj hauv kev tswj qhov ntsuas: Kev tsis ruaj khov ntawm cov dej ntws yaj, kev faib tawm qhov kub tsis sib xws thoob plaws lub pwm, thiab kev tsim cov pwm tuaj yeem ua rau muaj kev hloov pauv ntawm cov tuab zaj duab xis, ob qho tib si transversely thiab longitudinal. Qhov no cuam tshuam rau kev ua haujlwm tom qab ntawm zaj duab xis thiab cov yam ntxwv siv kawg.

6. Kev Hloov Resin Nyuaj: Thaum hloov ntawm ntau hom lossis qib ntawm polyolefin resins, lossis thaum hloov xim masterbatches, cov khoom seem los ntawm qhov kev khiav dhau los feem ntau nyuaj rau tshem tawm tag nrho ntawm extruder thiab pwm. Qhov no ua rau kev sib xyaw ua ke ntawm cov khoom qub thiab tshiab, tsim cov khoom hloov pauv, ntev lub sijhawm hloov pauv, thiab nce cov nqi pov tseg.

Cov teeb meem ua cov khoom no ua rau cov tuam txhab tsim cov yeeb yaj kiab polyolefin tsis muaj zog los txhim kho cov khoom zoo thiab kev ua haujlwm zoo, thiab tseem ua rau muaj kev cuam tshuam rau kev siv cov ntaub ntawv tshiab thiab cov txheej txheem ua haujlwm siab heev. Yog li ntawd, kev nrhiav cov kev daws teeb meem zoo los kov yeej cov teeb meem no yog qhov tseem ceeb rau kev txhim kho kev lag luam polyolefin tag nrho.

Cov Kev Dais Teeb Meem Rau Polyolefin Film Extrusion Process: Polymer Processing Aids (PPAs)

Cov Khoom Siv Pab Ua Polymer (PPAs) yog cov khoom siv ntxiv uas lawv lub ntsiab lus tseem ceeb yog txhim kho tus cwj pwm rheological ntawm cov polymer melts thaum lub sijhawm extrusion thiab hloov kho lawv cov kev sib cuam tshuam nrog cov khoom siv, yog li kov yeej ntau yam teeb meem ua tiav thiab txhim kho kev ua haujlwm zoo thiab cov khoom zoo.

1. Cov PPAs uas ua los ntawm Fluoropolymer

Cov Qauv Tshuaj thiab Cov Yam Ntxwv: Cov no yog cov chav kawm PPAs uas siv dav tshaj plaws, paub tab hauv kev siv tshuab, thiab pom tseeb tias muaj txiaj ntsig zoo. Lawv feem ntau yog homopolymers lossis copolymers raws li fluoroolefin monomers xws li vinylidene fluoride (VDF), hexafluoropropylene (HFP), thiab tetrafluoroethylene (TFE), nrog rau fluoroelastomers yog tus sawv cev tshaj plaws. Cov saw hlau molecular ntawm cov PPAs no muaj ntau cov zog sib txuas siab, cov polarity qis CF, uas muab cov khoom tshwj xeeb physicochemical: lub zog nto qis heev (zoo ib yam li polytetrafluoroethylene / Teflon®), kev ruaj khov thermal zoo heev, thiab kev tsis muaj tshuaj lom neeg. Qhov tseem ceeb, fluoropolymer PPAs feem ntau qhia txog kev sib raug zoo tsis zoo nrog cov matrices polyolefin uas tsis yog polar (xws li PE, PP). Qhov tsis sib xws no yog qhov tseem ceeb rau lawv txoj kev tsiv teb tsaws chaw mus rau qhov chaw hlau ntawm lub pwm, qhov twg lawv tsim cov txheej txheem lubricating dynamic.

Cov Khoom Sawv Cev: Cov hom lag luam ua lag luam thoob ntiaj teb rau fluoropolymer PPAs suav nrog Chemours 'Viton ™ FreeFlow ™ series thiab 3M's Dynamar ™ series, uas tswj hwm feem ntau ntawm kev ua lag luam. Tsis tas li ntawd, qee qib fluoropolymer los ntawm Arkema (Kynar® series) thiab Solvay (Tecnoflon®) kuj tseem siv ua, lossis yog cov khoom tseem ceeb hauv, PPA formulations.

2. Cov Khoom Siv Ua Haujlwm Raws Li Silicone (PPAs)

Cov Qauv Tshuaj thiab Cov Yam Ntxwv: Cov khoom tseem ceeb hauv chav kawm no ntawm PPAs yog polysiloxanes, feem ntau hu ua silicones. Lub pob txha caj qaum polysiloxane muaj cov silicon thiab cov pa oxygen atoms (-Si-O-), nrog rau cov pab pawg organic (feem ntau yog methyl) txuas rau cov silicon atoms. Cov qauv molecular tshwj xeeb no muab cov ntaub ntawv silicone nrog qhov tsis tshua muaj zog ntawm qhov chaw, kev ruaj khov thermal zoo heev, kev ywj pheej zoo, thiab cov khoom tsis nplaum rau ntau yam tshuaj. Zoo ib yam li fluoropolymer PPAs, silicone-based PPAs ua haujlwm los ntawm kev tsiv mus rau cov hlau ntawm cov khoom siv ua haujlwm los tsim cov txheej txheem lubricating.

Cov Nta ntawm Daim Ntawv Thov: Txawm hais tias fluoropolymer PPAs tswj hwm polyolefin zaj duab xis extrusion sector, silicone-based PPAs yuav ua rau pom cov txiaj ntsig tshwj xeeb lossis tsim cov teebmeem synergistic thaum siv rau hauv cov xwm txheej thov tshwj xeeb lossis ua ke nrog cov txheej txheem resin tshwj xeeb. Piv txwv li, lawv yuav raug txiav txim siab rau cov ntawv thov uas xav tau cov coefficients qis heev ntawm kev sib txhuam lossis qhov twg cov yam ntxwv tshwj xeeb ntawm qhov chaw xav tau rau cov khoom kawg.

Ntsib Kev Txwv Fluoropolymer lossis PTFE Cov Teeb Meem?

Kev daws teeb meem Polyolefin Film Extrusion nrog PFAS-Free PPA Solutions-SILIKE cov tshuaj ntxiv Fluorine Free Polymer

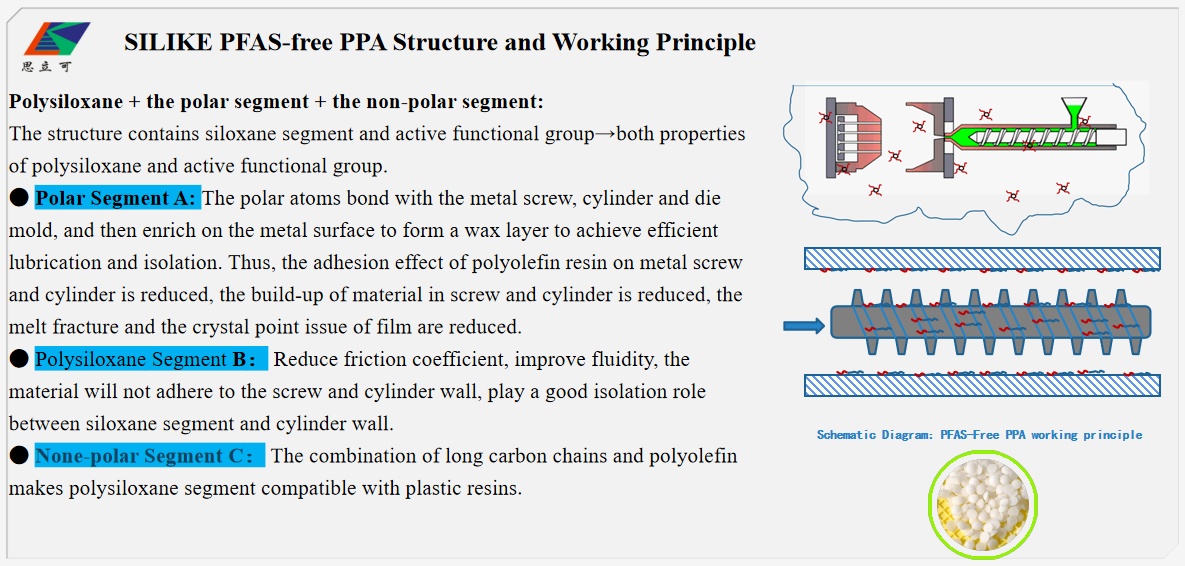

SILIKE siv txoj hauv kev ua ntej nrog nws cov khoom SILIMER series, muab cov khoom tshiabCov khoom siv ua cov polymer uas tsis muaj PFAS (PPAs)). Cov khoom lag luam no muaj 100% PFAS-dawb PPAs,Cov tshuaj ntxiv PPA Polymer uas tsis muaj fluorine, thiabCov PPA masterbatches uas tsis muaj PFAS thiab tsis muaj fluorineLos ntawmtshem tawm qhov xav tau cov tshuaj fluorine ntxiv, cov kev pab ua cov txheej txheem no ua rau cov txheej txheem tsim khoom zoo dua rau LLDPE, LDPE, HDPE, mLLDPE, PP, thiab ntau yam txheej txheem polyolefin zaj duab xis extrusion. Lawv ua raws li cov cai ib puag ncig tshiab thaum tseem ua kom muaj txiaj ntsig zoo dua, txo qis lub sijhawm tsis ua haujlwm, thiab txhim kho cov khoom zoo tag nrho. SILIKE's PFAS-free PPAs coj cov txiaj ntsig rau cov khoom kawg, suav nrog kev tshem tawm ntawm kev tawg ntawm cov tawv nqaij (sharkskin), txhim kho kev du, thiab qhov zoo ntawm qhov chaw.

Yog tias koj tab tom tawm tsam nrog qhov cuam tshuam ntawm fluoropolymer bans lossis tsis txaus ntawm PTFE hauv koj cov txheej txheem polymer extrusion, SILIKE muajlwm txoj hauv kev rau fluoropolymer PPAs / PTFE, Cov tshuaj ntxiv uas tsis muaj PFAS rau kev tsim zaj duab xisuas tau tsim los kom tau raws li koj xav tau, tsis tas yuav hloov cov txheej txheem.

Lub sijhawm tshaj tawm: Tsib Hlis-15-2025