Xim Masterbatch yog ib hom xim tshwj xeeb tshiab rau cov khoom siv polymer, tseem hu ua kev npaj xim. Nws muaj peb lub ntsiab lus tseem ceeb: xim lossis xim zas, tus nqa khoom thiab cov khoom ntxiv, thiab yog cov khoom sib xyaw ua ke tau los ntawm kev sib txuas ntau yam xim lossis xim zas rau cov resin. Cov khoom siv ua tiav yog qhov yuav tsum tau ua kom ntseeg tau tias ntau yam xim tuaj yeem tawg ua ke, kom tiv thaiv kev sib sau ua ke, thiab kom tsis txhob muaj teeb meem xws li kev tawg ntawm cov khoom yaj thiab txo cov pwm tsim thaum lub sijhawm ua tiav.

Muaj ntau yam khoom ntxiv rau hauv kev ua lag luam uas siv tau rau xim masterbatch, hom khoom ntxiv twg tuaj yeem daws cov teeb meem saum toj no tau zoo dua?

SILIMERcov koobsilicone hyperdispersant, Txhawb kom muaj kev sib kis zoo thiab sib xws ntawm cov hmoov xim

Teeb meem 1: Xim Masterbatch extrusion ntws cim, qhov chaw tsis zoo ntawm cov khoom hauv cov txheej txheem ntawm kev ua masterbatch.

Teeb Meem 2: Tus masterbatch spinning yog yooj yim tawg, tsis zoo extruding, thiab tus nqi lim dej tsis zoo.

Kev tshuaj xyuas qhov laj thawjQhov laj thawj tseem ceeb yog tias qhov loj me ntawm cov hmoov xim loj dhau lossis cov hmoov xim tsis sib npaug thiab sib sau ua ke hauv ib qho kev taw qhia thaum lub sijhawm ua tiav.

Kev daws teeb meem: SILIKE SILIMER series silicone hyperdispersantyog ib hom khoom siv hloov kho copolymer polysiloxane, uas tuaj yeem txhim kho qhov sib xws ntawm cov hmoov xim thiab cov khoom siv resin substrate, txhawb kev sib kis zoo thiab sib xws ntawm cov hmoov xim thiab ua kom nws ruaj khov, txawm tias chromaticity, txhim kho lub zog xim ntawm cov xim, txhim kho qhov fluidity ntawm lub kaw lus, txhim kho kev ua haujlwm, thiab lub sijhawm ntawd, nws tuaj yeem txo qhov coefficient sib txhuam ntawm qhov chaw los ntawm kev siv cov yam ntxwv ntawm cov saw hlau silicon lub zog tig qis, yog li nws tuaj yeem txhim kho qhov du ntawm cov khoom. Thiab nws tuaj yeem ua kom ntseeg tau tias muaj kev tsim khoom du ntawm extrusion spinning.

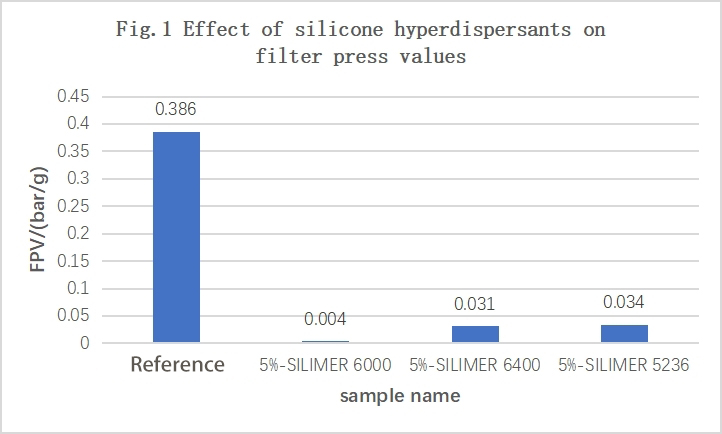

Raws li pom hauv daim duab 1, nyob rau hauv qhov kub thiab txias sim: 235 ℃; tag nrho cov qauv: 1000g; qhov hnyav ntawm cov xim: 80g; ntxiv masterbatch: 20%; substrate PP: 80%; lim specification: 1000 mesh xeem mob, nws tuaj yeem pom tias tom qab ntxiv SILIKE silicone hyperdispersantSILIMER6000, SILIMER6400, SILIMER5236rau tus masterbatch, qhov kev lim dej siab tau raug txo qis heev, uas qhia tau hais tiasSILIKE silicone hyperdispersantzoo txhim kho qhov agglomeration phenomenon ntawm cov hmoov, thiab ntxiv txhim kho qhov dispersibility ntawm cov hmoov. Cov dispersant siv tau los txhim kho qhov dispersibility ntawm cov hmoov.

SILIKE PFAS tsis muaj PPA Polymer Process Aid, Tshem tawm cov pob tawg uas yaj thiab txuas ntxiv cov voj voog ntxuav khoom siv

Teeb meem 3: Cov pwm xim masterbatch extrusion qhov hluav taws xob khaws cov khoom siv, thiab lub voj voog ntxuav khoom siv luv luv.

Kev tshuaj xyuas qhov laj thawj: Vim yog qhov tsis sib xws ntawm cov hmoov xim thiab cov khoom siv hauv paus, ib feem ntawm cov hmoov xim yooj yim kom sib xyaw tom qab sib tov, muaj qhov sib txawv ntawm qhov fluidity ntawm cov hmoov xim thiab cov resin thiab qhov viscosity ntawm cov yaj yog loj hauv cov txheej txheem ntawm extrusion, tib lub sijhawm, muaj qhov cuam tshuam viscous ntawm cov khoom siv hlau extrusion thiab cov txheej txheem resin, uas ua rau cov khoom tuag hauv lub cev chamber thiab extrusion ntawm lub qhov ncauj tuag, cov hmoov xim thiab cov thermoplastic resin raug stripped tawm thaum lub sijhawm ntawm extrusion ua rau lub qhov ncauj thiab tuag accumulation ntawm cov khoom siv, thiab lub luag haujlwm ntawm cov resin yaj thiab cov khoom siv hlau yuav tsum tau txo kom tsis txhob muaj qhov xwm txheej zoo li no. Nws yog qhov tsim nyog los ua kom tsis muaj zog ntawm kev sib cuam tshuam ntawm cov resin yaj thiab cov khoom siv hlau kom tsis txhob muaj qhov xwm txheej no.

Teeb Meem 4: Yaj tawg thaum lub sijhawm extrusion ceev, sib cais hmoov xim thiab nag lossis daus.

Kev tshuaj xyuas qhov laj thawj: Vim tias qhov nrawm ntawm cov khoom siv nws tus kheej me me thaum lub tshuab hmoov xim raug extruded ntawm qhov ceev ceev, yuav muaj teeb meem loj heev ntawm kev tawg thiab pwm tsim thaum extruded ntawm qhov ceev ceev, uas yuav ua rau muaj kev sib cais thiab nag ntawm cov hmoov xim. Fluoropolymer yog cov polymer viscosity siab hauv lub tshuab hmoov xim thaum lub sijhawm tsiv teb tsaws chaw sab nraud tsis zoo, qhov cuam tshuam kev txhim kho yog qhov dav dav.

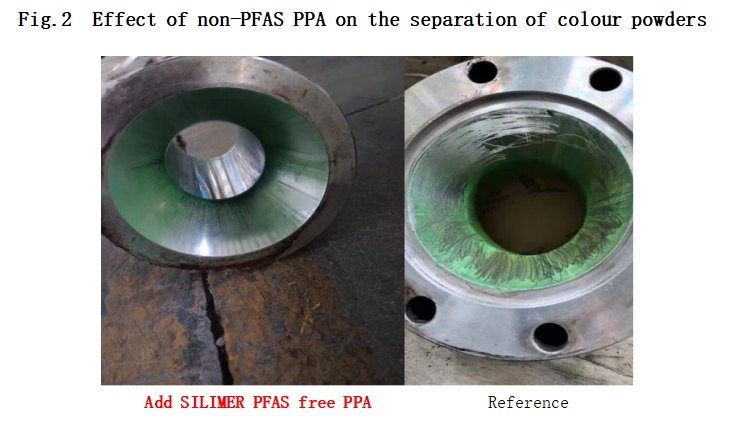

Kev daws teeb meem: Cov khoom siv ua PPA uas tsis muaj SILIKE PFASyog ib yam khoom siv polysiloxane masterbatch uas tau hloov kho los ntawm cov organic uas sib xyaw cov saw hlau polysiloxane nrog cov pab pawg polar, sib xyaw ua ke qhov kev ua tau zoo heev ntawm ob qho tib si, thiab txhim kho cov qauv tib lub sijhawm. Fluorine-free PPA txais yuav cov pab pawg hloov kho uas tuaj yeem sib xyaw ua ke nrog cov ntsia hlau hlau kom hloov lub luag haujlwm ntawm fluorine hauv fluorine-muaj PPA, thiab tom qab ntawd siv cov yam ntxwv qis zog ntawm silicone los tsim cov yeeb yaj kiab silicone ntawm qhov chaw ntawm cov khoom siv hlau kom ua tiav qhov cuam tshuam ntawm kev rho tawm, uas ua rau lub voj voog ntxuav ntawm cov khoom siv ntev dua kom luv lub sijhawm tsis ua haujlwm, tshem tawm cov pob tawg yaj, txo cov pwm tsim, thiab txhim kho lub luag haujlwm ntawm qhov zoo ntawm qhov chaw. Tsis tas li ntawd, nws kuj muaj cov yam ntxwv ntawm kev tiv thaiv ib puag ncig tsis yog PFAS, txo qhov extrusion torque, txhim kho kev ua haujlwm fluidity thiab lwm yam.

Raws li pom hauv Daim Duab 2, tom qab tus neeg siv khoom sivCov Khoom Siv Ua Polymer SILIKE PFAS uas tsis muaj, tib lub sijhawm ua tiav, cov hmoov xim lo rau ntawm phab ntsa sab hauv ntawm lub tshuab tau zoo dua qub.

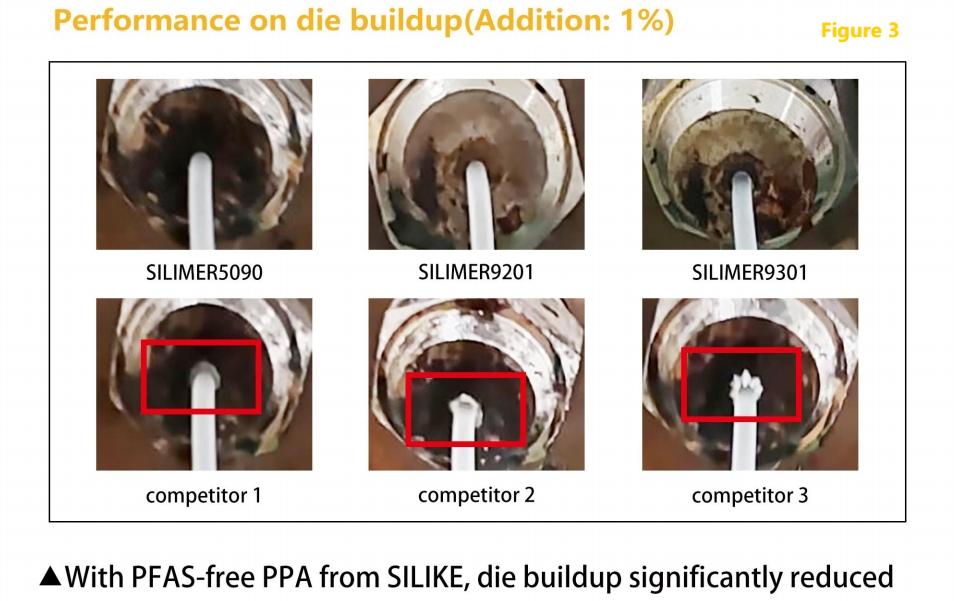

Raws li pom hauv daim duab 3, nyob rau hauv 30 feeb extrusion mob thiab tib qhov ntxiv, qhov kev txhim kho ntawm SILIKE tsis yog-PFAS PPA ntawm kev tsim cov pwm yog qhov zoo dua li ntawm fluorinated PPA.

Cov chaw tsim khoom xim Masterbatch, yog tias koj ntsib teeb meem lossis teeb meem thaum lub sijhawm ua masterbatch, thov hu rau peb, SILIKE tuaj yeem muab cov kev daws teeb meem rau koj.

Chengdu SILIKE Technology Co., Ltd, tus thawj coj hauv Suav tebCov Khoom Siv SiliconeTus neeg muab khoom rau cov yas hloov kho, muab cov kev daws teeb meem tshiab los txhim kho kev ua tau zoo thiab kev ua haujlwm ntawm cov khoom siv yas. Txais tos tiv tauj peb, SILIKE yuav muab cov kev daws teeb meem ua cov yas zoo rau koj.

Contact us Tel: +86-28-83625089 or via email: amy.wang@silike.cn.

lub vas sab:www.siliketech.comkom paub ntau ntxiv.

Lub sijhawm tshaj tawm: Lub Kaum Hli-16-2024