Kev Nkag Siab Txog Kev Lag Luam Txog Kev Txhim Kho Kev Ua Haujlwm Nylon Hauv Cov Ntawv Thov Uas Siv Tau Ntev

Hauv kev hloov pauv tas li ntawm cov yas engineering, cov ntaub ntawv nylon uas tiv taus kev hnav tseem ua lub luag haujlwm tseem ceeb hauv ntau yam lag luam. Txij li cov khoom siv hauv tsheb mus rau cov tshuab kev lag luam, qhov kev thov rau cov nylon ruaj khov, kev sib txhuam tsawg tau tsav tsheb tsim kho tshiab hauv kev tshawb fawb txog cov ntaub ntawv.

Ib txwm muajCov Kev Daws Teeb Meemrau Nylon Hnav Tiv Thaiv

Cov zej zog engineering tau tsim ntau txoj hauv kev zoo los txhim kho kev tiv thaiv kev hnav ntawm PA6 thiab PA66, cov hom nylon feem ntau siv hauv kev siv hauv kev lag luam.

1. Kev Txhawb Nqa Iav Fiber:Cov iav fiber ntxiv dag zog nylon (GF/PA6, GF/PA66) yog tsim los ntawm kev sib xyaw cov iav fibers rau hauv cov nylon matrix, tsim cov khoom sib xyaw ua ke zoo uas txhim kho cov khoom siv kho tshuab zoo heev. Cov fibers tsim cov network 3D txhawb nqa, txhim kho lub zog tensile (txog li 4 ×), kev tawv (3-5 × siab dua flexural modulus), thiab kev tiv taus cua sov (50-100 ° C siab dua HDT) los ntawm kev hloov pauv khoom siv tau zoo. Raws li cov ntsiab lus fiber, cov composites no muaj los ntawm cov qib qis-fiber (10%-20%), nruab nrab-fiber (25%-35%), siab-fiber (40%-50%), thiab ultra-high-fiber (> 50%). Cov ntsiab lus fiber ntau dua 30% tshwj xeeb ua rau qhov zoo tshaj plaws kev tiv taus hnav. Kev sib xyaw ua ke no ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov kev lag luam uas xav tau.

2. Kev Txhawb Nqa Carbon Fiber:Ntxiv cov carbon fiber rau PA6/PA66 ua rau muaj zog thiab hnav tsis kam zoo dua. Tsis zoo li lwm cov ntaub ntawv txhawb nqa, carbon fiber yog mos mos nrog kev sib txhuam tsawg, tiv thaiv kev puas tsuaj rau cov hlau thaum sib txhuam. Cov nqi ntxiv feem ntau yog txij li 5% txog 20%, nrog rau kev siv ua haujlwm siab siv txog li 30%.

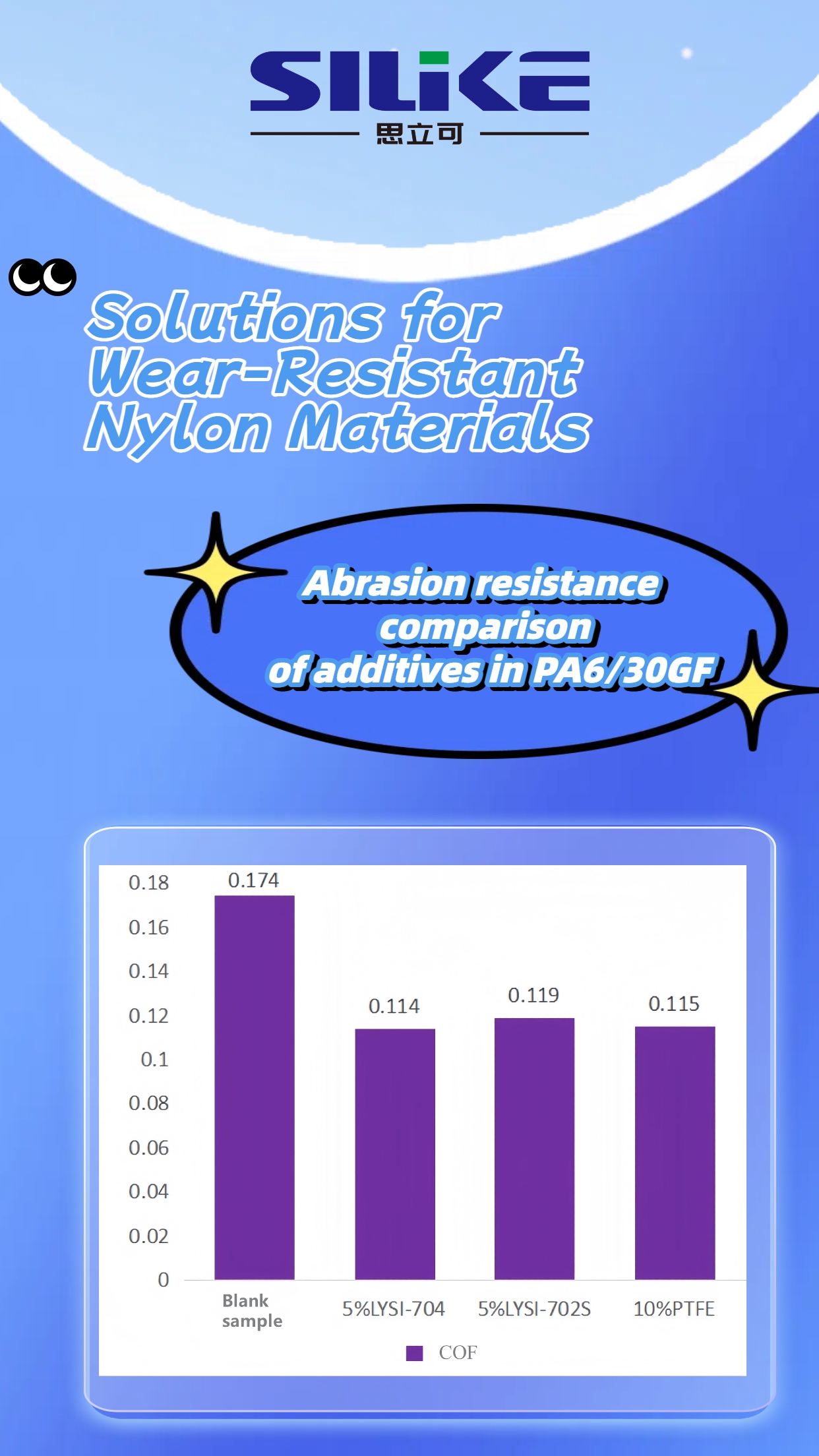

3. Cov Khoom Sib Xyaws PTFE/PA6:Nrog cov coefficients sib txhuam qis heev, PTFE tsim cov zaj duab xis lubricating thaum lub sijhawm sib txhuam, ua rau nws tsim nyog rau cov ntawv thov siab. Cov nqi ntxiv hauv PA6 feem ntau yog li ntawm 15% txog 20%.

4. Molybdenum Disulfide (MoS2) / PA66 Cov Khoom Sib Xyaws: Ua ib qho crystallization promoter, molybdenum disulfide ua rau nylon crystallinity ntau ntxiv, tsim cov nplaim tawv dua thiab tiv taus hnav dua. Nws qhov kev sib raug zoo siab rau cov hlau tso cai rau nws kom sau cov qhov me me ntawm cov nplaim hlau, tsim cov interfaces du dua. Qhov no ua rau nws zoo tagnrho rau cov ntawv thov nylon-hlau sib txhuam, nrog rau cov nqi ntxiv ib txwm muaj ntawm 3% txog 15%.

5. Graphite-Hloov PA66:Cov khoom ntxiv graphite ua rau cov coefficients sib txhuam txo qis thaum txhim kho cov yam ntxwv ntawm kev sib txhuam. Cov qauv graphite ua rau yooj yim txav thaum sib txhuam, txo qhov hnav. Qhov kev hloov kho no zoo heev rau hauv cov dej, nrog rau cov nqi ntxiv ib txwm muaj ntawm 3% thiab 15%.

Cov Teeb Meem Tshiab hauv Nylon Hnav Tiv Thaiv: Kev Sib Npaug ntawm Kev Ua Haujlwm, Tus Nqi, thiab Kev Ruaj Ntseg

Txawm hais tias muaj cov kev daws teeb meem no los xij, cov tuam txhab tsim khoom tau tawm tsam ntev los ntawm kev sib npaug ntawm cov kev xav tau kev ua tau zoo nrog rau kev xav txog tus nqi thiab kev thov kom ruaj khov. Cov khoom siv ntxiv ib txwm muaj feem ntau xav tau cov theem thauj khoom siab, uas tuaj yeem cuam tshuam rau cov yam ntxwv ntawm kev ua thiab ua rau cov nqi khoom siv nce ntxiv.

"Kev lag luam tau nrhiav kev daws teeb meem uas tuaj yeem ua rau muaj kev tiv thaiv kev hnav zoo tshaj plaws yam tsis muaj qhov tsis zoo uas cuam tshuam nrog cov khoom ntxiv ib txwm muaj," qee tus kws tshaj lij polymer engineering sau tseg. "Kev daws teeb meem zoo tshaj plaws yuav xav tau qhov ntxiv tsawg kawg nkaus thaum tswj hwm lossis txhim kho cov khoom siv kho tshuab ntawm cov khoom siv."

Kev tsim kho tshiabCov Kev Dais Teeb Meem Rau Cov Yas Engineering Nylon Uas Tiv Thaiv Tau Kev Hnav

Chengdu Silike Technology Co., Ltd. tau yog ib lub tuam txhab tsim khoom tshiab thiab tsim cov khoom siv silicone polymer ua tau zoo txij li xyoo 2004. Peb tshwj xeeb hauv kev siv tshuab silicone rau kev lag luam roj hmab thiab yas, peb muab cov khoom siv ua tiav tshiab uas daws cov teeb meem nyuaj hauv kev tsim khoom thiab txhim kho cov khoom siv rau kev siv thoob ntiaj teb. Txhawm rau teb rau cov teeb meem no, peb tau tsim ib qhocov khoom siv silicone ua haujlwm siab thiab tiv taus kev hnav LYSI-704,tsim los ua kom zoo dua qub rau kev hloov kho nylon thaum txhawb nqa kev tsim khoom ruaj khov.

Vim li cas SILIKE Tus Neeg Sawv Cev Uas Tiv Thaiv Tau Kev Hnav LYSI-704 Hloov Nylon Kev Ua Haujlwm? Dab Tsi Ua Rau LYSI-704 Txawv?

Cov tshuaj ntxiv tiv thaiv kev hnav LYSI-704 tshiab, raws li cov qauv polysiloxane tshwj xeeb, tsis zoo li cov tshuaj ntxiv tiv thaiv kev hnav ib txwm muaj, LYSI-704 ua tiav kev sib kis thoob plaws nylon matrices ntawm tus nqi ntxiv qis heev. Qhov no tsim cov txheej roj nplua nyeem uas ruaj khov uas txo cov coefficients sib txhuam thaum khaws cia cov khoom siv lub hauv paus kev ua haujlwm zoo.

"Dab tsi ua rau cov thev naus laus zis no zoo kawg nkaus yog nws qhov xwm txheej ntau yam," piav qhia txog tus kws tshawb fawb thiab kev txhim kho los ntawm SILIKE uas tsom mus rau kev siv silicone hauv cov yas engineering. "Thaum koom ua ke rau hauv PA6 + iav fiber systems los ntawm kev sib xyaw ua ke, LYSI-704 tsis yog tsuas yog xa cov khoom siv hnav zoo sib xws rau PTFE-raws li cov kev daws teeb meem tab sis kuj txhim kho lub zog cuam tshuam - kev sib xyaw ua ke uas yav dhau los xav tias tsis yooj yim sua.

Tej zaum qhov tseem ceeb tshaj plaws rau cov chaw tsim khoom uas txhawj xeeb txog kev zoo nkauj, cov khoom siv ntxiv rau cov yas /Modifier LYSI-704 kuj daws qhov teeb meem ntawm cov fiber floating uas tau ua rau cov iav-reinforced nylons, qhib cov cib fim tshiab rau cov ntawv thov uas qhov zoo ntawm qhov chaw tseem ceeb heev.

Ntxiv mus, vim muaj kev txhawj xeeb txog kev ruaj khov txuas ntxiv mus rau kev txiav txim siab xaiv cov khoom siv, LYSI-704 silicone-based chemistry muab lwm txoj hauv kev tsis muaj fluorine rau cov khoom siv PTFE ib txwm muaj, ua raws li cov kev pib thoob ntiaj teb los txo kev siv cov tshuaj fluorinated. Lub peev xwm ntawm cov thev naus laus zis los xa cov kev ua tau zoo tshaj plaws ntawm cov nqi ntxiv qis kuj txhais tau tias txo qis kev siv cov peev txheej thiab tej zaum yuav txo qis cov pa roj carbon footprints thoob plaws hauv cov txheej txheem tsim khoom.

Rau cov chaw tsim khoom siv yas engineering uas tab tom nrhiav kev sib tw zoo los ntawm kev tsim kho tshiab ntawm cov khoom siv, cov thev naus laus zis tshiab no uas siv silicone ua cov khoom siv ntxiv rau kev puas tsuaj muab cov cib fim zoo hauv kev ua lag luam uas xav tau ntau ntxiv, thaum qhib cov cib fim tshiab rau kev tsim kho daim ntawv thov.

Koj puas npaj txhij los txhim kho koj cov khoom nylon nrog cov thev naus laus zis tshiab uas tsis yooj yim hnav?

Yog koj tab tom nrhiavcov kev daws teeb meem zoo los txhim kho kev hnav tsis kam ntawm koj cov nyloncov khoom, kev tsim kho tshiab zoo li SILIKE LYSI-704 cov khoom siv tiv thaiv kev hnav qhia txog kev coj ua tshiab rau cov khoom siv tsim, thiab yog qhov kev tawg tshiab uas koj tau tos. Nws muab kev ruaj khovlwm txoj hauv kev rau cov tshuaj ntxiv PTFE ib txwm muajTiv tauj peb hnub no kom paub seb cov khoom siv ntxiv thiab cov khoom hloov kho tshiab no tuaj yeem hloov koj cov yas engineering li cas thaum ua raws li koj lub hom phiaj kev ruaj khov.

Tel: +86-28-83625089 or via Email: amy.wang@silike.cn. Website:www.siliketech.com

Lub sijhawm tshaj tawm: Tsib Hlis-22-2025