Cov yeeb yaj kiab Thermoplastic Polyurethane (TPU) muaj npe nrov rau lawv qhov kev ywj pheej tshwj xeeb, kev ruaj khov, thiab cov yam ntxwv ua tau zoo, ua rau lawv yog qhov kev xaiv zoo tshaj plaws hauv kev lag luam xws li tsheb, kev kho mob, zam, thiab cov khoom siv hluav taws xob. Thaum cov yeeb yaj kiab TPU txheem tau txais txiaj ntsig rau lawv qhov kev tiv thaiv kev sib txhuam thiab kev ruaj khov tshuaj lom neeg, cov yeeb yaj kiab TPU matte tau txais kev rub tawm tseem ceeb vim lawv qhov kev zoo nkauj, txo qhov ci ntsa iab, thiab cov nplaim tiv taus ntiv tes.

Txawm li cas los xij, kev ua tiav qhov tiav matte zoo thiab zoo ntawm TPU zaj duab xis tuaj yeem nyuaj. Cov teeb meem xws li cov qauv tsis sib xws, lub teeb tsis sib kis, thiab qhov tsis zoo ntawm qhov chaw feem ntau ua rau cov chaw tsim khoom ntxhov siab. Tsab xov xwm no tshawb nrhiav cov txheej txheem npaj tau ua pov thawj rau cov yeeb yaj kiab TPU matte, daws cov teeb meem tseem ceeb thiab muab cov kev daws teeb meem uas ua tau los pab koj tsim cov khoom zoo meej.

Cov Txheej Txheem Npaj Rau Matte TPU Zaj Duab Xis

1. Kev Xaiv Cov Resin thiab Cov Khoom Ntxiv: Lub Hauv Paus ntawm Matte TPU Films

Txoj kev mus rau kev tsim cov yeeb yaj kiab TPU zoo pib nrog kev xaiv cov ntaub ntawv zoo.

1.1 TPU Resin

Kev xaiv cov TPU resin uas tsim nyog yog qhov tseem ceeb heev. Cov kev xav tseem ceeb suav nrog:

Kev Nyuaj: Cov resins nruab nrab-nyuaj rau tawv yog qhov zoo tagnrho rau kev tswj hwm qhov chaw kom ruaj khov thaum ua kom muaj kev ywj pheej.

Kev ywj pheej: Kev ywj pheej ntau dua yog qhov tseem ceeb rau cov ntawv thov uas xav tau kev khoov lossis ncab, xws li cov khoom siv hauv tsheb lossis khau.

Kev Sib Xws Ua Haujlwm: Xyuas kom tseeb tias cov roj hmab sib xws nrog koj txoj kev ua haujlwm xaiv (extrusion, calendering, thiab lwm yam).

1.2Cov Neeg Sawv Cev Rau Matting

Txoj kev ua tau zoo tshaj plaws thiab siv dav tshaj plaws rau kev tsim cov zaj duab xis TPU matte yog kev sib xyaw TPU nrog cov khoom ntxiv tshwj xeeb uas txo qhov ci ntsa iab thiab muab nws ua tiav matte. Cov khoom ntxiv no, feem ntau hu uacov neeg sawv cev rau matting ,cov tshuaj pleev xim, los yogTPU tsis ci ntsa iab ntxiv,tau koom ua ke rau hauv TPU thaum lub sijhawm ua cov txheej txheem sib xyaw.cov khoom siv ntxiv rau matteua haujlwm los ntawm kev cuam tshuam qhov du ntawm zaj duab xis, ua rau lub teeb tawg thiab ua rau pom matte. Cov hom matting agents feem ntau suav nrog:

Cov Neeg Sawv Cev Matting Uas Muaj Silica: Cov khoom me me silica no cuam tshuam qhov du ntawm qhov chaw, tsim kom muaj cov qauv ntxhib uas ua rau lub teeb tawg.

Cov Neeg Sawv Cev Polymeric Matting: Cov neeg sawv cev no feem ntau yog cov sib xws ntau dua thiab muab kev sib kis zoo dua hauv TPU matrix.

Calcium Carbonate: Txawm hais tias tsis tshua siv ntau npaum li silica lossis polymeric agents, nws tuaj yeem siv rau hauv qee cov formulations rau qhov tiav matte.

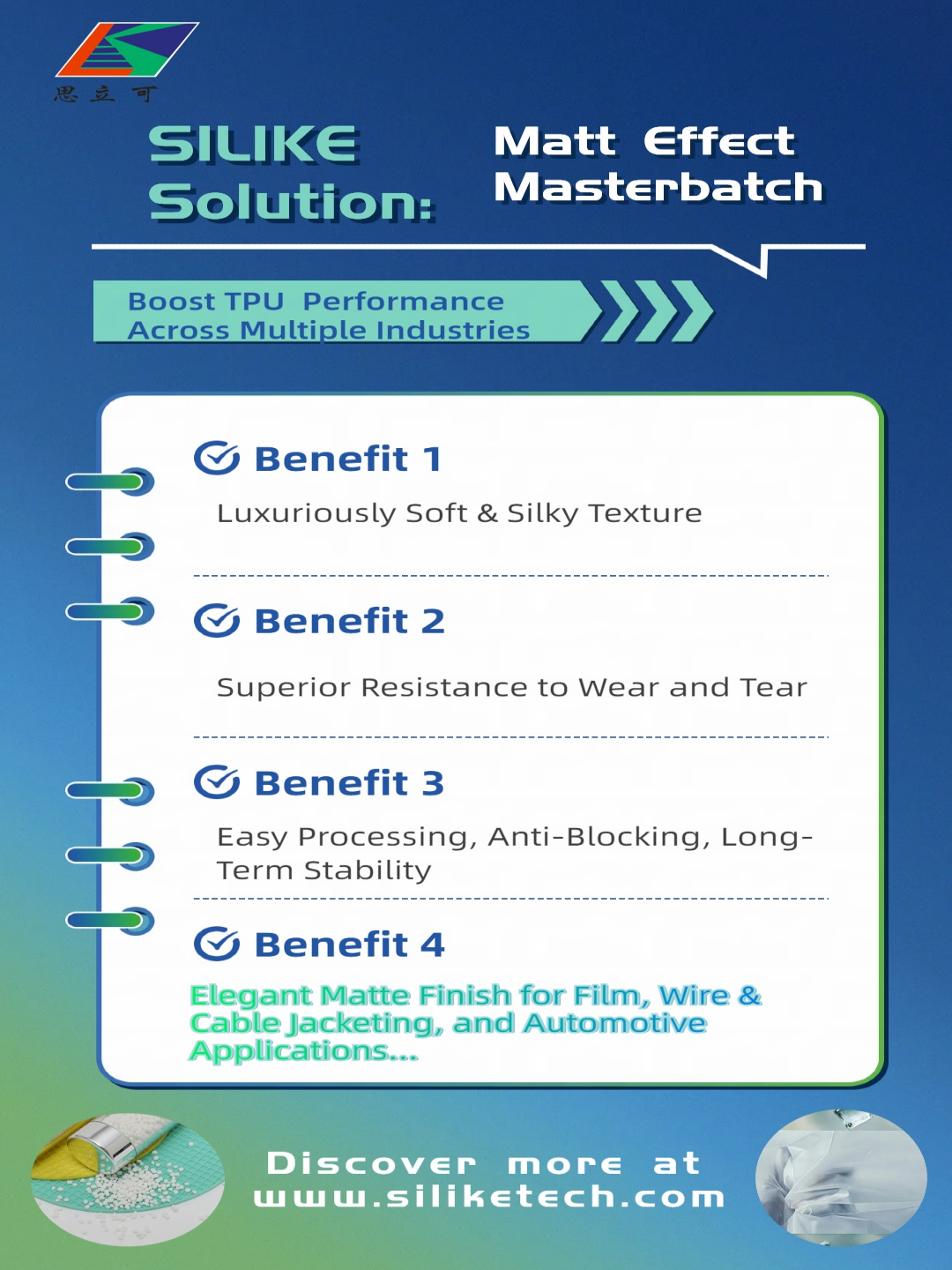

Cov Lus Qhia Zoo: Txhim Kho Kev Ruaj Khov thiab Kev Thov Matte: SILIKE's TPU raws li Masterbatch Solutions

Matt Effect Masterbatchyog ib qho Matting Agent tshiab tsim los ntawm SILIKE, siv thermoplastic polyurethane (TPU) ua nws tus cab kuj. Sib xws nrog ob qho tib si polyester-based thiab polyether-based TPU, tus neeg sawv cev matting no yog tsim los txhim kho qhov tsos matte, kov nto, ruaj khov, thiab tiv thaiv kev thaiv ntawm TPU zaj duab xis thiab lawv cov khoom kawg.

Qhov tseem ceeb ntawmSILIKE's Polyester TPU-based thiab Polyether TPU-based Matt Effect Masterbatch lnws yooj yim heev—nws tuaj yeem muab tso ncaj qha thaum lub sijhawm ua haujlwm, tshem tawm qhov xav tau granulation, thiab ua kom tsis muaj kev pheej hmoo ntawm nag txawm tias siv ntev.

Nws zoo meej rau cov ntawv thov uas xav tau cov khoom tiav zoo tshaj plaws, xws li TPU zaj duab xis siv hauv kev ntim khoom, tsheb, khau, khoom siv kho mob, thiab cov khoom siv hluav taws xob rau cov neeg siv khoom.

Tshwj xeeb tshaj yog,Matt Effect Masterbatch 3235yog qhov zoo tagnrho rau kev tsim cov polyester TPU matte tiav zoo tshaj plaws rau cov ntawv thov ntim khoom.

1.3 Cov Khoom Ntxiv

Yuav kom txhim kho kev ua tau zoo ntxiv, xav txog kev suav nrog:

Cov Tshuaj Tiv Thaiv Kev Thaiv Tiv thaiv cov yeeb yaj kiab kom tsis txhob lo ua ke thaum lub sijhawm khaws cia.

UV Stabilizers: Tiv thaiv kev puas tsuaj ntawm UV, zoo tagnrho rau kev siv sab nraum zoov.

Cov Tshuaj Pleev: Txhim kho cov yam ntxwv ntawm qhov chaw pleev kom yooj yim dua rau kev tuav.

2. Txheej Txheem Extrusion: Kev Ntsuas Yog Qhov Tseem Ceeb

Kev rho tawm yog txoj hauv kev siv ntau tshaj plaws rau kev tsim cov yeeb yaj kiab TPU. Yuav kom ua tiav qhov tiav matte zoo meej:

2.1 Lub Tshuab Extruder Twin-Screw

Lub tshuab extruder twin-screw ua kom muaj kev sib xyaw zoo dua thiab kev sib kis ntawm cov neeg sawv cev matting, ua rau muaj qhov tsos matte zoo ib yam.

2.2 Kev Tswj Kub

Tswj qhov kub kom raug kom tsis txhob muaj qhov tsis zoo ntawm qhov chaw xws li npuas, kab txaij, lossis qhov ci tsis sib xws.

2.3 Tsim Qauv Tuag

Siv lub pwm tiaj tiaj nrog qhov chaw tiav matte lossis muab cov ntawv txias txias los qhia cov qauv nto xav tau.

3. Cov Txuj Ci Kho Qhov Nto: Txhim Kho Qhov Matte Effect

Kev kho kom zoo nkauj ntawm qhov chaw tuaj yeem ua kom zoo dua qhov tiav matte thiab txhim kho kev ua haujlwm:

3.1 Txheej

Siv cov txheej txheej matte siv cov txheej txheem dov lossis tshuaj tsuag kom txhim kho cov qauv ntawm qhov chaw yam tsis hloov pauv cov khoom sib xyaw TPU.

3.2 Kev kos duab

Dhau cov zaj duab xis los ntawm cov menyuam embossing nrog cov qauv matte los tsim cov qauv tsa rau qhov tiav tas li.

3.3 Kev Siv Tshuaj Etching

Siv cov tshuaj kho mob me me los hloov kho qhov roughness ntawm qhov chaw, ua tiav cov qauv matte zoo ib yam rau cov ntawv thov siab.

4. Cov Txheej Txheem Ua Yeeb Yaj Kiab Los Ntawm Cua Thiab Cov Txheej Txheem Ua Yeeb Yaj Kiab Uas Siv Cua: Xaiv Txoj Kev Zoo

Qhov kev xaiv ntawm cov txheej txheem zaj duab xis blown thiab cast nyob ntawm seb koj xav tau cov yam ntxwv zaj duab xis li cas:

4.1 Cov Txheej Txheem Ua Yeeb Yam Cuav

Zoo tagnrho rau cov yeeb yaj kiab tuab dua, cov txheej txheem cua txias siv cua txias kom ua tiav qhov tiav matte ntuj.

4.2 Cov Txheej Txheem Ua Yeeb Yam

Qhov zoo tshaj plaws rau cov yeeb yaj kiab nyias dua, cov txheej txheem zaj duab xis siv cov ntawv txias dov los tsim kom muaj qhov tiav matte zoo ib yam thiab zoo.

5. Cov Txuj Ci Tom Qab Ua Haujlwm: Ua kom tiav qhov tiav

Kev ua tiav tom qab tuaj yeem ua kom cov nyhuv matte zoo dua thiab txhim kho kev ua tau zoo ntawm zaj duab xis:

5.1 Kev Siv Calender

Dhau cov zaj duab xis los ntawm cov menyuam calendering los kho qhov zoo nkauj thiab tuab ntawm qhov chaw, kom ntseeg tau tias muaj qhov tiav matte zoo ib yam.

5.2 Kev Laminating

Siv cov zaj duab xis TPU matte los txuas nrog lwm cov ntaub ntawv kom txhim kho lub zog, kev ruaj khov, lossis cov khoom thaiv thaum khaws cov tsos matte.

5.3 Kev Xuab Zeb Nto

Siv cov khoom siv kho tshuab los txhim kho cov qauv matte, tsim kom muaj qhov chaw tiav rau cov ntawv thov siab.

Ib Daim Ntawv Qhia Txog Matte TPU Films: SILIKE's Matt Effect Masterbatch Muab Kev Pabcuam

SILIKE'sMatt Effect Masterbatchmuab kev daws teeb meem txhim khu kev qha thiab ua haujlwm tau zoo rautsim cov yeeb yaj kiab TPU zoo matteNrog kev yooj yim koom ua ke thaum lub sijhawm ua tiav thiab kev ruaj khov mus sij hawm ntev, nws yog qhov kev xaiv zoo meej rau cov chaw tsim khoom uas tab tom nrhiav kev txhim kho lawv cov khoom.

Koj puas muaj teeb meem nrog TPU Film Gloss? Los yog, npaj txhij los ua tiav Premium Matte Finishes rau koj qhov kev tsim TPU Film?

Tiv tauj SILIKE—tusKev tsim khoom Matte Effect Masterbatch- kom paub ntau ntxiv txog kev tsim kho tshiabTPU Matt Effect Masterbatch kev daws teeb meemthiab thov kom muaj cov qauv ntawm peb cov Anti-blocking Matte Effect Additives!

Xov tooj: +86-28-83625089,Email: amy.wang@silike.cn, Lub Vev Xaib: www.siliketech.com

Lub sijhawm tshaj tawm: Lub Peb Hlis-05-2025