Yog dab tsiWPC roj nplua nyeem?

WPC ua cov khoom siv ntxiv(kuj hu uaCov roj nplua nyeem rau WPC, los yogtus neeg sawv cev rau WPC) yog cov roj nplua nyeem uas mob siab rau kev tsim thiab ua cov ntoo-yas composites (WPC): Txhim kho kev ua haujlwm ntawm cov txheej txheem, txhim kho qhov zoo ntawm cov khoom, xyuas kom meej cov khoom siv lub cev, txo qhov sib txhuam ntawm cov polymer sib xyaw thiab cov tshuab ua haujlwm, txo cov khoom siv hnav, thiab cov extrusion molding du. Qhov zoo ntawmCov roj nplua nyeem ntxiv rau WPCmuaj kev cuam tshuam loj heev rau lub neej ua haujlwm ntawm pwm, lub thoob thiab ntsia hlau hauv kev ua cov ntoo yas, lub peev xwm tsim khoom ntawm extruder, kev siv hluav taws xob hauv cov txheej txheem tsim khoom, qhov tiav ntawm cov khoom thiab qhov kub qis cuam tshuam kev ua tau zoo ntawm cov profiles. Thiab yog tias ntxiv stearate hauv kev pab ua ntoo nrog MAH yuav ua rau cov nyhuv crosslinking ntawm maleic anhydride tsis muaj zog, yog li ntawd, tus neeg sawv cev crosslinking thiab cov roj nplua nyeem yuav txo qis.

Kev xaiv ntawmCov tshuaj roj nplua nyeem rau WPCxav txog cov kev cai hauv qab no:

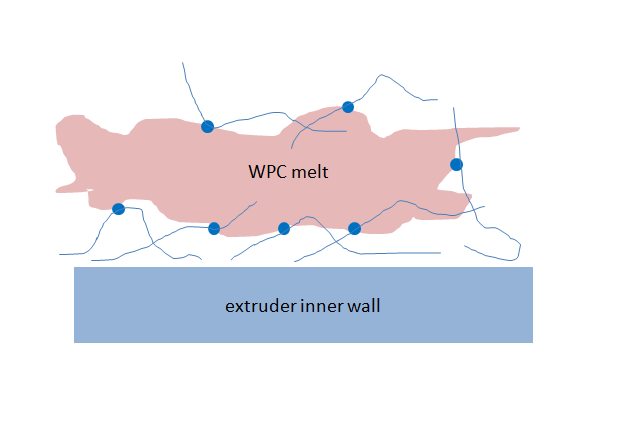

Nws muaj kev sib raug zoo nrog cov resin ntawm qhov kub siab, tuaj yeem tsim cov nyhuv yas, txo cov zog sib koom ua ke ntawm cov molecules hauv cov resin, ua rau cov molecules tsis muaj zog.

, qhov kev sib txhuam ntawm ib leeg, txo qhov viscosity ntawm cov resin yaj, txhim kho cov dej ntws yaj, txhawb kev swb ntawm cov khoom siv resin.

Cov khoom WPC muaj ntau daim ntawv thov, cov no txhua tus yuav siv cov roj nplua nyeem thaum lub sijhawm tsim khoom kom zoo dua ntawm qhov chaw decking, sidings, phab ntsa cladding daim ntawv thov kom txhim kho kev ua tiav thiab muab qhov zoo dua ntawm qhov chaw, thiab lwm yam.

Cov roj nplua nyeem WPC zoo tshaj plaws yuav tsum muaj ntau yam haujlwm, lub hom phiaj yog ua kom cov khoom siv ua si zoo tshaj plaws, ua kom ntau lawm, thiab txhim kho qhov zoo ntawm cov khoom:

1、 Kev sib cuam tshuam ntawm cov polymers/polymers hauv molecular

2, Ua kom cov nyhuv yas nrawm dua;

3, Txo cov viscosity yaj;

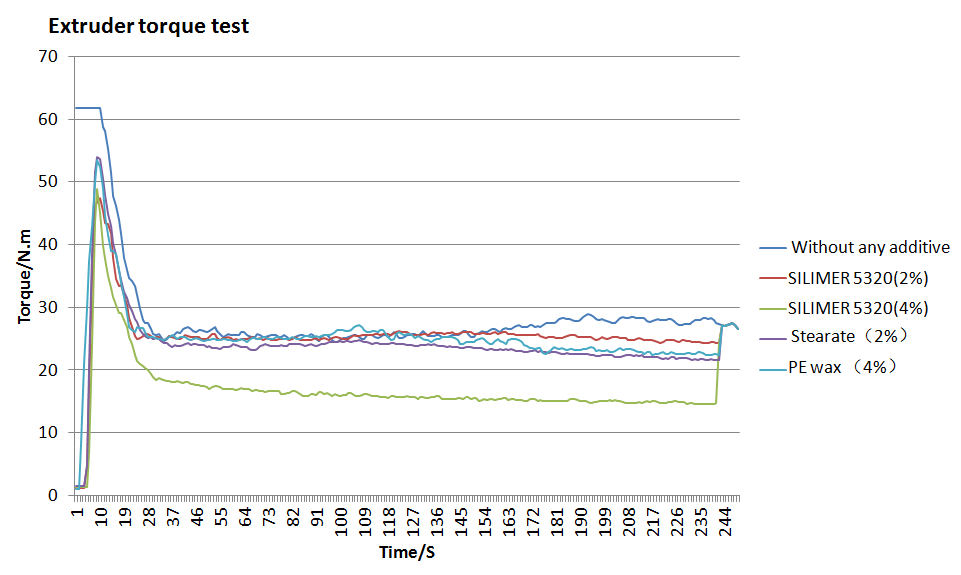

4, Txo qhov torque thiab kev siv hluav taws xob;

5, Kev sib cuam tshuam ntawm Polymer / filler interface

6, Txhawb kom muaj kev sib kis ntawm cov hmoov ntoo lossis cov khoom siv fiber ntuj;

7, Pab txhawb rau qhov ntub ntawm cov khoom sau;

8, Lubricated puv polymer thiab cua sov lossis txias hlau interface;

9, Txhim kho cov khoom siv demolding ntawm cov khoom siv hauv lub thoob extrusion thiab qhov chaw tuag;

10, Txo kev sib txhuam thiab kev hnav;

11, Muab cov roj nplua nyeem sab hauv & sab nraud rau cov khoom WPC

Muaj ntau yam sib txawvcov roj nplua nyeem ntoo yasxws liCov roj nplua nyeem ua los ntawm silicone SILIKE Silimer 5400, ethylene bis-stearamide (EBS), zinc stearate, paraffin waxes, thiab oxidized PE. Thiab dab tsi yog covQhov sib txawv ntawm cov roj nplua nyeem wpcQhov hnyav molecular, koob tshuaj, kev ua tau zoo yog cov yam ntxwv sib txawv nrog kev ua tau zoo sib txawv.Cov roj nplua nyeem uas ua los ntawm siliconeLawv tiv taus kev hnav thiab tsim kua muag, nrog rau cua sov thiab tshuaj lom neeg. Lawv kuj tsis muaj tshuaj lom thiab tsis kub hnyiab, ua rau lawv yog qhov kev xaiv zoo tshaj plaws rau ntau yam kev siv. Cov roj nplua nyeem ua los ntawm silicone kuj tseem tuaj yeem txo qhov kev sib txhuam ntawm cov khoom txav mus los, uas tuaj yeem pab txuas lub neej ntawm WPCs.

Yuav ua li cas txog qhov koob tshuaj ntawm cov roj nplua nyeem ntoo yas?

Feem ntau, cov yas ntoo sib xyaw (WPC) siv cov roj nplua nyeem ob npaug ntau dua li cov yas ib txwm. Rau cov yas sib xyaw ntoo uas muaj cov ntoo fiber ntau ntawm 50% ~ 60%, cov roj nplua nyeem ntawm cov khoom siv HDPE yog 4% ~ 5%, cov roj nplua nyeem ntawm cov khoom siv PP yog 1% ~ 2%, thiab cov roj nplua nyeem ntawm cov khoom siv PVC yog 5% ~ 10%. Txawm li cas los xij, qhov ntau npaum li cas tiag tiag tuaj yeem hloov kho raws li cov qauv sib txawv thiab cov txheej txheem ntawm cov tuam txhab.SILIKE silimer 5400yuav muab kev ua tau zoo dua nrog cov koob tshuaj me dua nrog 1.5% ~ 3%.

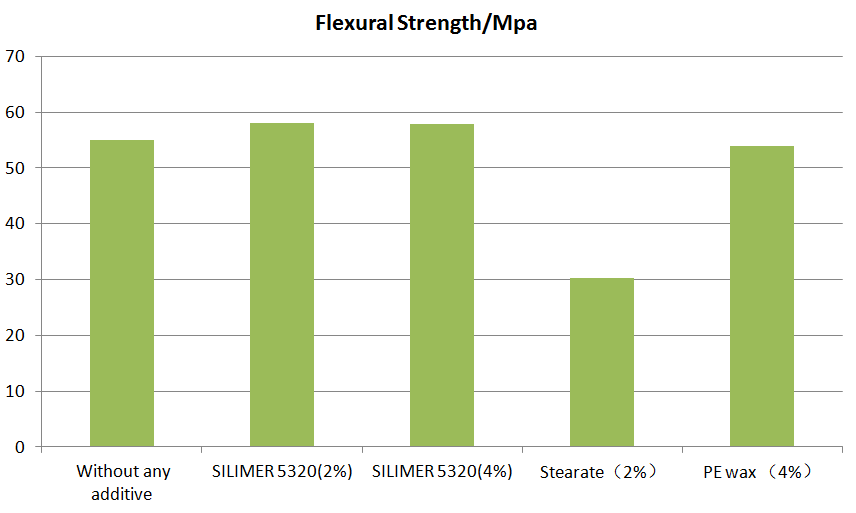

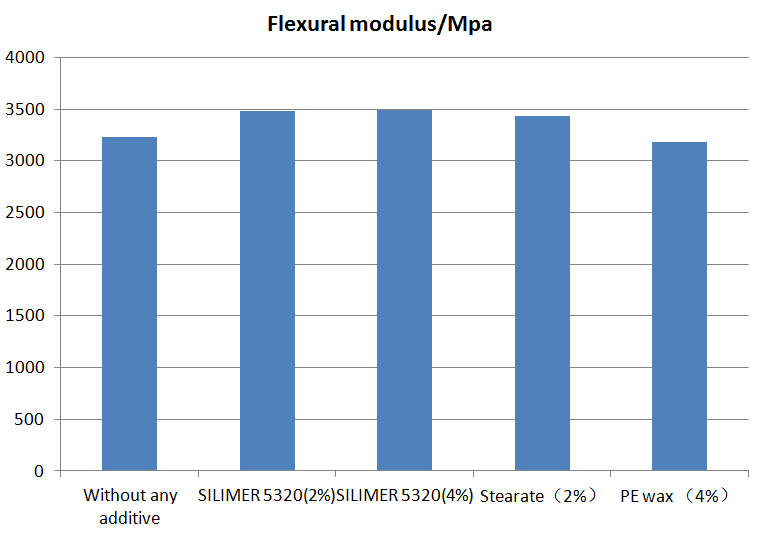

Chengdu Silike Technology Co., LtdTuam Tshoj WPC lubricant chaw tsim khoommuabCov roj nplua nyeem raws li silicone rau WPCCov tshuaj ntxiv no yog tsim tshwj xeeb rau kev ua thiab tsim cov PE WPC thiab PP WPC (cov khoom siv ntoo yas) xws li WPC decking, WPC laj kab, thiab lwm yam WPC composites, thiab lwm yam. Lub hauv paus ntawm cov tshuaj roj no rau WPC yog hloov kho polysiloxane, muaj cov pab pawg polar active, sib xws zoo heev nrog cov resin thiab hmoov ntoo, thaum ua thiab tsim khoom tuaj yeem txhim kho kev sib kis ntawm cov hmoov ntoo, tsis cuam tshuam rau qhov sib xws ntawm cov compatibilizers hauv lub kaw lus, tuaj yeem txhim kho cov khoom siv kho tshuab ntawm cov khoom. Tus neeg sawv cev tso tawm no rau WPC composites muab kev ua tau zoo dua li ethylene bis-stearamide (EBS), zinc stearate, paraffin waxes, thiab oxidized PE, thiab cov roj no pheej yig nrog lubrication zoo heev, tuaj yeem txhim kho cov khoom ua matrix resin, tab sis kuj ua rau cov khoom du, muab koj cov ntoo yas composites ib daim duab tshiab.

Qhov noCov roj nplua nyeem zoo tshaj plaws ntawm WPCSilimer 5400 muab ntau yam txiaj ntsig nrog rau hauv qab no:

1, Txhim kho kev ua tiav, txo qhov extruder torque, txhim kho kev faib tawm ntawm cov khoom sau;

2. MuabLubricant sab hauv thiab sab nraud rau WPC, txo kev siv hluav taws xob thiab ua kom muaj txiaj ntsig zoo dua;

3, Kev sib raug zoo nrog hmoov ntoo, tsis cuam tshuam rau cov zog ntawm cov molecules ntawm cov ntoo yas sib xyaw thiab tswj cov khoom siv kho tshuab ntawm lub substrate nws tus kheej;

4, Txo cov khoom sib xws, txo cov khoom tsis zoo, txhim kho cov tsos ntawm cov khoom yas ntoo;

5, Tsis muaj nag los tom qab sim ua kom npau, khaws ciakev du mus sij hawm ntev.

Tsim kho tshiab silicone, Txhawb kom muaj txiaj ntsig tshiab.

Lub sijhawm tshaj tawm: Lub Rau Hli-09-2023