Hauv kev lag luam tsheb, qhov ruaj khov, kev zoo nkauj, thiab kev noj qab haus huv ntawm cov khoom yas sab hauv yog qhov tseem ceeb tshaj plaws.

Polypropylene (PP) tau dhau los ua ib qho ntawm cov ntaub ntawv siv dav tshaj plaws hauv kev kho tsheb sab hauv, ua tsaug rau nws cov khoom sib dua, kev siv nyiaj tsim nyog, thiab kev hloov pauv tau yooj yim. Txawm li cas los xij, nws qhov kev cuam tshuam rau kev khawb thiab kev hloov pauv tseem yog qhov mob loj - tshwj xeeb tshaj yog nyob rau hauv thaj chaw muaj neeg coob xws li dashboards, qhov rooj vaj huam sib luag, thiab cov consoles nruab nrab. Txhawm rau daws qhov teeb meem no, cov tshuaj tiv thaiv khawb ntxiv rau polypropylene thaum lub sijhawm tsim khoom. Tab sis nrog ntau txoj kev xaiv hauv khw, koj xaiv qhov zoo tshaj plaws li castshuaj ntxiv tiv thaiv khawbe? Cov tshuaj ntxiv tiv thaiv khawb twg yog qhov kev xaiv zoo tshaj plaws rau kev kho kom zoo nkauj sab hauv tsheb? Cia peb tshawb nrhiav cov kev xav tseem ceeb thiab cov neeg sib tw saum toj kawg nkaus.

Cov Khoom Siv Tiv Thaiv Kev Khawb Zoo Tshaj Plaws rau Polypropylene

Muaj ntau hom tshuaj ntxiv uas tiv thaiv kev khawb, txhua yam muaj nws cov txiaj ntsig tshwj xeeb. Nov yog cov kev xaiv uas feem ntau siv:

1. SILIKESilicone Masterbatch Anti-Scratch Series

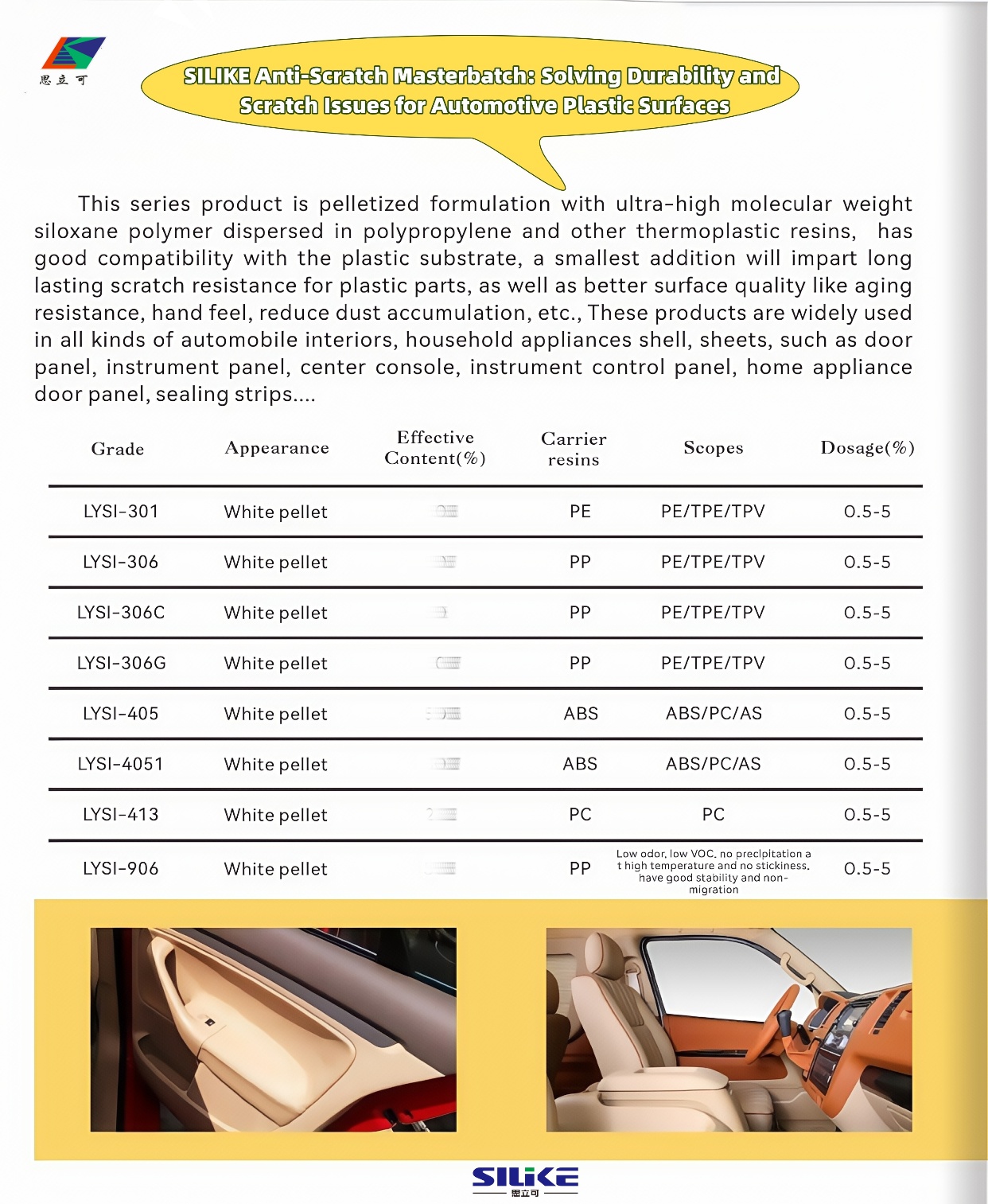

SILIKE'sCov Tshuaj Masterbatch Tiv Thaiv Kev Khawbyog ib qho pelletized formulation nrog ultra-high molecular weight siloxane polymers dispersed nyob rau hauv polypropylene thiab lwm yam thermoplastic resins. Qhov notshuaj ntxiv rau kev tiv thaiv khawbmuaj kev sib raug zoo heev nrog cov yas substrate. Cov nocov khoom siv tiv thaiv martxhim kho kev sib raug zoo nrog Polypropylene (CO-PP/HO-PP) matrix, ua rau muaj kev sib cais theem qis dua ntawm qhov chaw kawg. Qhov no txhais tau tias nws nyob ntawm qhov chaw ntawm cov yas kawg yam tsis muaj kev tsiv teb tsaws chaw lossis kev tawm mus, txo cov pos huab, VOCs, lossis ntxhiab tsw.

Ib qho ntxiv me me ua rau cov khoom yas tiv taus khawb tau ntev, nrog rau qhov zoo dua ntawm qhov chaw, suav nrog kev tiv taus kev laus, kev kov tes, thiab txo cov hmoov av. Cov khoom siv tiv taus khawb no siv dav hauv PP, TPO, TPE, TPV, PC, ABS, thiab PC/ABS cov ntaub ntawv hloov kho, hauv cov khoom siv hauv tsev, cov plhaub khoom siv hauv tsev, thiab cov ntawv, xws li cov vaj huam sib luag qhov rooj, dashboards, consoles nruab nrab, vaj huam sib luag ntsuas, vaj huam sib luag qhov rooj khoom siv hauv tsev, thiab cov ntaub nplaum.

Cov txiaj ntsig: Muab kev tiv thaiv khawb zoo tshaj plaws rau PP thiab TPO cov khoom siv hauv lub cev tsheb. Cov pelletized formulation nrog ultra-high molecular weight siloxane polymer ua kom muaj kev sib raug zoo thiab VOCs qis.

Siv Cov Ntaub Ntawv: Zoo tagnrho rau kev siv sab hauv tsheb, xws li kev txhim kho cov khoom tiv thaiv kev khawb ntawm TPE, TPV, PP, thiab PP/PPO talc-filling systems.

Hauv SILIKE qhov kev sim hauv chav kuaj, los ntawm kev ntxiv 1.5-3% anti-scratch silicone masterbatch LYSI-306C rau hauv PP / TPO system, qhov kev sim tiv thaiv khawb tuaj yeem dhau thiab ua tau raws li VW's PV3952 thiab GM's GMW14688 cov qauv. Nyob rau hauv lub siab ntawm 10 N, ΔL tuaj yeem ua tiav <1.5, tsis muaj kev nplaum thiab VOCs qis.

2. DuPont MULTIBASE™ HMB-0221, MB50-001, thiab MB50-0221/G2

Cov txiaj ntsig: Cov tshuaj ntxiv no ua rau nws tiv taus khawb tau zoo, ua tau raws li tus qauv VW PV3952. Lawv muaj cov polymers siloxane uas hnyav molecular heev thiab txhim kho kev tiv taus UV yam tsis muaj exudation.

Siv Cov Lus Qhia: Haum rau cov khoom siv PP copolymer zoo nrog talc, muab kev tiv thaiv khawb zoo dua thiab kev ruaj khov UV.

Lub Tswv Yim Zoo: Raws li cov lus tawm tswv yim ntawm cov neeg siv khoom, SILIKE's Anti-Scratch Masterbatch LYSI-306 yog kev lag luam tawm tsam rau MB50-001. Hauv kev sim ua haujlwm tau zoo, SILIKE Silicone Masterbatch Anti-Scratch LYSI-306C tau ua tiav qhov kev tiv thaiv khawb sib npaug rau MB50-0221 / G2.

(Ceeb Toom: Tsab xov xwm no yog rau kev qhia xov xwm xwb. Cov ntaub ntawv kev ua tau zoo raws li kev sim sab hauv ntawm SILIKE. Cov txiaj ntsig yuav txawv raws li cov xwm txheej ntawm cov khoom siv.)

3. TEGOMER® AntiScratch 100 los ntawm Evonik

Cov txiaj ntsig: TEGOMER® AntiScratch 100 muaj kev tiv thaiv kev tsiv teb tsaws chaw, kev tiv thaiv khawb mus tas li rau cov tshuaj PP. Nws tuaj yeem ua ke nrog cov khoom nqus ntxhiab yam tsis txo qhov kev ua haujlwm tiv thaiv khawb.

Kev Siv: Zoo rau kev daws teeb meem ntsig txog qib talc sib txawv lossis qib thauj khoom hauv cov khoom sib xyaw PP hauv tsheb.

Thaum xaiv cov tshuaj tiv thaiv khawb rau PP hauv kev siv tsheb, xav txog cov hauv qab no:

1.Kev Sib Xws: Xyuas kom tseeb tias cov khoom ntxiv sib xws nrog PP thiab txhua yam khoom siv.

2. Kev Tiv Thaiv Kev Khawb: Nrhiav cov khoom ntxiv uas ua tau raws li cov qauv kev lag luam, xws li VW PV3952.

3. Kev Ruaj Ntseg Ib Puag Ncig: Xaiv cov khoom ntxiv uas muab kev ruaj ntseg UV thiab tsis muaj cov kua tawm.

4. Kev Ua Raws Cai: Xyuas kom ua raws li cov cai ntawm kev lag luam tsheb txog kev tso pa phem thiab kev nyab xeeb.

Nrog cov tshuaj ntxiv tiv thaiv kev khawb kom raug, koj tuaj yeem tiv thaiv koj lub tsheb sab hauv kom tsis txhob muaj kev khawb tsis zoo, tswj lawv qhov zoo nkauj, thiab txhim kho kev ruaj khov tag nrho. Txawm tias koj ua haujlwm nrog polypropylene lossis TPO systems, muaj ib qho kev daws teeb meem uas ua tau raws li koj cov kev xav tau tshwj xeeb.

Xav kom koj lub tsheb tsis khawb los yog puas yooj yim khawb?

Tiv tauj peb hnub no kom paub ntau ntxiv txog SILIKE cov khoom siv siab heevcov tshuaj tiv thaiv khawbor cov kev daws teeb meem hloov kho qhov tsis kam ntawm mar.

Tel: +86-28-83625089, Email: amy.wang@silike.cn, Website: www.siliketech.com

Lub sijhawm tshaj tawm: Lub Peb Hlis-12-2025