Si-TPV kua rau cov ntaub laminated mos mos lossis daim ntaub mesh clip uas tiv taus cov av

Si-TPV tshuaj rau cov ntaub mos mos lossis cov ntaub mesh uas tiv taus cov xim av,

daim ntaub mesh clip, cov ntaub sib xyaw ua ke, Si-TPV zaj duab xis, TPU, TPU zaj duab xis sib xyaw cov ntaub ntawv sib xyaw, TPU laminated ntaub,

PIAV TXOG

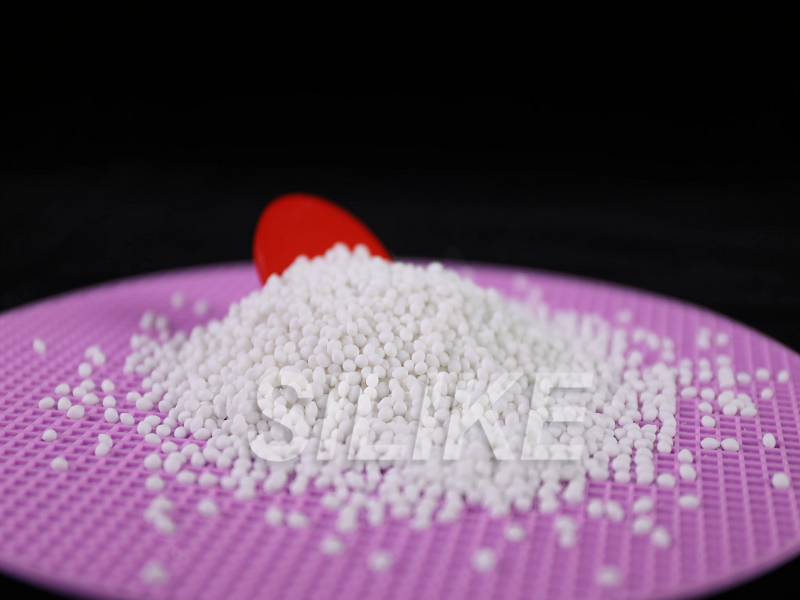

SILIKE Si-TPV® thermoplastic elastomer yog ib qho patented dynamic vulcanized thermoplastic silicone-based elastomer uas ua los ntawm cov thev naus laus zis tshwj xeeb los pab cov roj hmab silicone dispersed hauv TPU sib npaug li 2 ~ 3 micron particles hauv qab microscope. Cov ntaub ntawv tshwj xeeb no ua ke lub zog, toughness thiab abrasion tsis kam ntawm txhua yam thermoplastic elastomer nrog cov khoom zoo ntawm silicone: softness, silky xav, UV lub teeb thiab tshuaj lom neeg tsis kam uas tuaj yeem rov ua dua thiab rov siv dua hauv cov txheej txheem tsim khoom ib txwm muaj.

Si-TPV® 3520-70A thermoplastic elastomer yog ib yam khoom siv uas muaj kev sib txhuam zoo thiab mos mos uas tuaj yeem sib txuas zoo rau PC, ABS, TPU thiab cov khoom siv polar zoo sib xws. Nws yog ib yam khoom tsim los rau kev kov silky overmolding ntawm cov khoom siv hluav taws xob hnav tau, cov thawv khoom siv rau cov khoom siv hluav taws xob, cov hlua saib.

DAIM NTAWV THOV

Kev daws teeb meem rau kev kov mos mos hla molding ntawm cov xov tooj ntse, cov ntaub ntawv hluav taws xob portable, smartwatch wristband, straps, thiab lwm yam khoom siv hluav taws xob hnav tau.

COV KHOOM SIV LI CAS

| Kev Ntsuas* | Vaj tse | Chav tsev | Qhov tshwm sim |

| ISO 868 | Qhov nyuaj (15 vib nas this) | Ntug dej A | 71 |

| ISO 1183 | Lub zog nqus tshwj xeeb | – | 1.11 |

| ISO 1133 | Cov Ntsuas Kev Ntws Yaj 10 kg & 190 ° C | g/10 feeb | 48 |

| ISO 37 | Modulus ntawm Elasticity (MOE) | MPa | 6.4 |

| ISO 37 | Lub zog tensile | MPa | 18 |

| ISO 37 | Kev Nyuaj Siab Tensile @ 100% Elongation | MPa | 2.9 |

| ISO 37 | Kev ntev thaum tawg | % | 821 |

| ISO 34 | Lub zog tsim kua muag | kN/m2 | 55 |

| ISO 815 | Kev Teeb Tsa Compression 22 teev @ 23°C | % | 29 |

*ISO: Lub Koom Haum Txheem Thoob Ntiaj Teb ASTM: Lub Koom Haum Asmeskas rau Kev Ntsuas thiab Cov Khoom Siv

COV NTAUB NTAWV & COV TXHOJ ZOO

(1) Kev xav mos mos

(2) Kev tiv thaiv khawb zoo

(3) Kev sib txuas zoo heev rau PC, ABS

(4) Hydrophobic heev

(5) Kev tiv thaiv xim av

(6) UV ruaj khov

YUAV SIV LI CAS

• Phau Ntawv Qhia Txog Kev Txhaj Tshuaj Molding

| Lub Sijhawm Qhuav | 2–6 teev |

| Kub Qhuav | 80–100°C |

| Qhov Kub ntawm Thaj Chaw Pub Noj | 150–180°C |

| Qhov Kub thiab Txias ntawm Cheeb Tsam Nruab Nrab | 170–190°C |

| Kub ntawm Thaj Chaw Pem Hauv Ntej | 180–200°C |

| Qhov Kub ntawm Nozzle | 180–200°C |

| Kub yaj | 200°C |

| Kub ntawm pwm | 20–40°C |

| Kev Ceev Txhaj Tshuaj | Nruab Nrab |

Cov txheej txheem no yuav txawv nrog cov khoom siv thiab cov txheej txheem ntawm tus kheej.

• Qib Thib ObKev Ua Haujlwm

Ua ib yam khoom siv thermoplastic, cov khoom Si-TPV® tuaj yeem ua tiav theem ob rau cov khoom ib txwm muaj

•Kev txhaj tshuajKev ua pwmSiab

Qhov siab tuav feem ntau nyob ntawm qhov geometry, tuab thiab qhov chaw ntawm lub qhov rooj ntawm cov khoom. Qhov siab tuav yuav tsum tau teeb tsa rau tus nqi qis thaum xub thawj, thiab tom qab ntawd maj mam nce mus txog thaum tsis pom qhov tsis zoo cuam tshuam hauv cov khoom txhaj tshuaj pwm. Vim yog cov khoom siv elastic ntawm cov khoom, qhov siab tuav ntau dhau yuav ua rau lub qhov rooj ntawm cov khoom puas tsuaj loj heev.

• Siab rov qab

Nws raug pom zoo tias lub zog rov qab thaum lub hau ntswj raug rub tawm yuav tsum yog 0.7-1.4Mpa, uas yuav tsis tsuas yog ua kom muaj kev sib npaug ntawm cov yaj yaj, tab sis kuj ua kom cov khoom tsis raug puas tsuaj los ntawm kev txiav. Qhov ceev ntsia hlau pom zoo ntawm Si-TPV® yog 100-150rpm kom ntseeg tau tias cov khoom yaj thiab yas tag nrho yam tsis muaj kev puas tsuaj los ntawm kev txiav cua sov.

COV LUS CEEV FAIB TXOG KEV TUAV KHOOM

Lub tshuab ziab khaub ncaws uas muaj desiccant dehumidifying raug pom zoo rau txhua qhov kev ziab.

Cov ntaub ntawv kev nyab xeeb ntawm cov khoom uas xav tau rau kev siv kom muaj kev nyab xeeb tsis suav nrog hauv daim ntawv no. Ua ntej siv, nyeem cov ntawv qhia txog cov khoom thiab kev nyab xeeb thiab cov ntawv lo rau lub thawv kom paub siv kom muaj kev nyab xeeb, cov ntaub ntawv txog kev phom sij rau lub cev thiab kev noj qab haus huv. Daim ntawv qhia txog kev nyab xeeb muaj nyob rau ntawm lub vev xaib ntawm lub tuam txhab silike ntawm siliketech.com, lossis los ntawm tus neeg faib khoom, lossis los ntawm kev hu rau Silike cov neeg pabcuam rau cov neeg siv khoom.

LUB NEEJ SIV TAU THIAB CIA KHOOM

Kev thauj mus los ua cov tshuaj tsis muaj kev phom sij. Khaws cia rau qhov chaw txias thiab muaj cua nkag tau zoo. Cov yam ntxwv qub tseem zoo li qub tau 24 lub hlis txij li hnub tsim khoom, yog tias khaws cia rau hauv qhov chaw cia khoom pom zoo.

COV NTAUB NTAWV TXOG NTIM KHOOM

25KG / hnab, hnab ntawv ua tes ua nrog PE sab hauv hnab.

TXWV

Cov khoom no tsis raug kuaj thiab tsis tau sawv cev tias tsim nyog rau kev siv tshuaj lossis tshuaj.

COV NTAUB NTAWV TXOG KEV POV THAWJ TXWV - THOV NYEM QHIA UA KOM ZOO

Cov ntaub ntawv muaj nyob hauv no yog muab los ntawm kev ntseeg siab zoo thiab ntseeg tau tias yog qhov tseeb. Txawm li cas los xij, vim tias cov xwm txheej thiab cov txheej txheem siv peb cov khoom tsis yog peb txoj kev tswj hwm, cov ntaub ntawv no yuav tsum tsis txhob siv los hloov cov neeg siv khoom qhov kev sim kom ntseeg tau tias peb cov khoom muaj kev nyab xeeb, ua haujlwm tau zoo, thiab txaus siab rau qhov kev siv kawg. Cov lus qhia ntawm kev siv yuav tsum tsis txhob raug coj los ua kev ntxias kom ua txhaum cai patent.

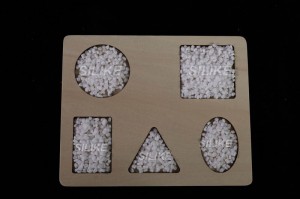

Cov ntaub TPU laminated yog siv TPU zaj duab xis los sib xyaw ntau yam ntaub los ua cov khoom sib xyaw, TPU laminated ntaub nto muaj cov haujlwm tshwj xeeb xws li dej tsis nkag thiab noo noo permeability, tiv taus hluav taws xob, tiv taus kev sib txhuam, ntxuav tau los ntawm lub tshuab ntxhua khaub ncaws, tiv taus kev sib txhuam, thiab tiv taus cua. Yog li, TPU raug suav hais tias yog qhov kev xaiv zoo tshaj plaws rau cov ntaub laminated lossis clip mesh daim ntaub.

Txawm li cas los xij, muaj teeb meem hauv cov txheej txheem tsim khoom ntawm TPU laminated ntaub, feem ntau ntawm lawv yuav TPU zaj duab xis los ntawm cov chaw tsim khoom zaj duab xis sab nraud thiab tsuas yog ua tiav cov txheej txheem ntawm kev nplaum thiab laminating. Hauv cov txheej txheem ntawm kev txuas tom qab, qhov kub siab thiab siab siab raug siv rau TPU zaj duab xis dua. Kev tswj cov txheej txheem tsis raug yuav ua rau puas tsuaj rau zaj duab xis thiab txawm tias qhov me me.

SILIKE Dynamic vulcanizate thermoplastic Silicone-based elastomers (Si-TPV) muab cov khoom siv tshiab zoo tagnrho rau cov ntaub laminated lossis daim ntaub clip-mesh.

COV KHOOM SIV SILICONE DAWB THIAB COV QAUV Si-TPV NTAU TSHAJ 100 QIB

Hom qauv

$0

- 50+ xyoo

Qib Silicone Masterbatch

- 10+ xyoo

qib Silicone Hmoov

- 10+ xyoo

qib Anti-scratch Masterbatch

- 10+ xyoo

Qib Anti-abrasion Masterbatch

- 10+ xyoo

Qib Si-TPV

- 8+

qib Silicone Wax

-

Xov tooj

-

Email

-

Whatsapp

Whatsapp

-

Sab saum toj

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-300x199.jpg)