Ntsib High Torque, Die Drool, lossis Poor Flow hauv LSZH Cable Compounds?

Cov ntaub ntawv cable uas tsis muaj pa luam yeeb tsawg (LSZH) tseem ceeb heev rau kev nyab xeeb thiab kev ruaj khov ntawm cable niaj hnub no. Txawm li cas los xij, kev ua tiav cov txheej txheem zoo heev tseem yog qhov nyuaj. Kev siv ntau ntawm cov khoom siv tiv thaiv hluav taws - xws li txhuas hydroxide (ATH) thiab magnesium hydroxide (MDH) - feem ntau ua rau tsis muaj zog ntws, muaj zog siab, ua tiav qhov chaw tsis zoo, thiab pwm sib sau ua ke thaum lub sijhawm extrusion.

Vim li cas LSZH Cable Compounds thiaj nyuaj rau ua tiav?

Cov yam ntxwv ntawm cov hlau thiab cov cable uas tsis muaj pa luam yeeb tsawg yog tias txhua yam khoom siv tsis muaj halogen, thiab yuav muaj pa luam yeeb me me thaum lub sijhawm hlawv. Yuav kom ua tiav ob yam tseem ceeb no, ntau cov tshuaj tua hluav taws tau ntxiv rau hauv cov txheej txheem tsim khoom, uas ua rau muaj ntau yam teeb meem ua tiav.

Cov hauv qab no yog cov teeb meem uas feem ntau tshwm sim thaum siv cov khoom siv hluav taws xob uas tsis muaj pa luam yeeb tsawg:

1. Vim muaj ntau cov khoom siv tiv thaiv hluav taws xws li txhuas hydroxide thiab magnesium hydroxide ntxiv rau, uas ua rau tsis muaj peev xwm ntws, thiab kev sib txhuam cua sov thaum lub sijhawm ua haujlwm ua rau kub nce, uas ua rau txhuas hydroxide thiab magnesium hydroxide puas tsuaj.

2. Kev ua haujlwm extrusion qis, thiab txawm tias qhov ceev extrusion siab dua, lub peev xwm extrusion tseem tsis hloov pauv.

3. Vim yog qhov tsis sib xws ntawm cov polyolefins nrog cov nplaim taws retardants thiab lwm yam fillers, uas ua rau muaj kev tawg tsis zoo thaum lub sijhawm ua thiab txo cov khoom siv kho tshuab.

4. Qhov kev sib kis tsis sib xws ntawm cov tshuaj tua hluav taws inorganic hauv lub kaw lus ua rau muaj qhov chaw ntxhib thiab tsis muaj qhov ci ntsa iab thaum lub sijhawm extrusion.

5. Qhov polarity ntawm cov nplaim taws retardant thiab lwm yam fillers ua rau cov yaj lo rau lub taub hau tuag, ncua cov khoom demoulding, lossis cov nag ntawm cov molecules qis hauv cov formulation, uas ua rau cov khoom sib sau ua ke ntawm lub qhov ncauj tuag, yog li cuam tshuam rau qhov zoo ntawm lub cable.

Yuav ua li cas los daws cov teeb meem ntawm LSZH cable thiab qhov zoo ntawm qhov chaw?

Yuav kom kov yeej cov teeb meem no,Cov txheej txheem silicone masterbatchtau dhau los ua ib qho kev daws teeb meem ntseeg siab hauv LSZH cov qauv sib xyaw, txhim kho ob qho tib si kev ua haujlwm zoo thiab kev ua haujlwm ntawm qhov chaw yam tsis muaj kev cuam tshuam rau cov khoom siv kho tshuab lossis hluav taws xob.

Vim li cassilicone masterbatch yog ib qho kev daws teeb meem zoorau kev txhim kho cov txheej txheem ua thiab kev ua haujlwm ntawm qhov chaw ntawm LSZH cable compounds?

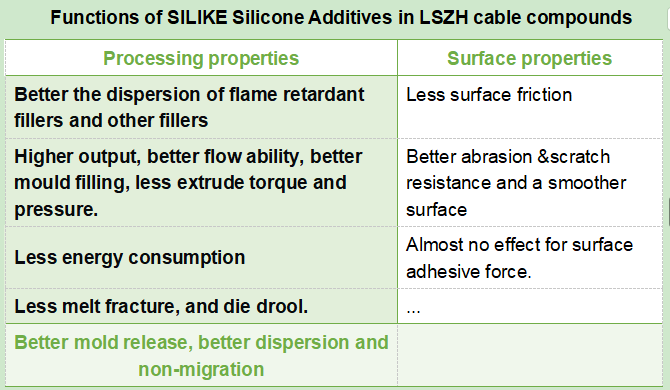

Silicone masterbatch yog ib hom ntawmcov khoom siv ua haujlwm ntxivnrog ntau yam thermoplastics ua tus nqa khoom thiab polysiloxane ua cov khoom ua haujlwm. Ntawm ib sab tes, silicone based masterbatch tuaj yeem txhim kho lub peev xwm ntws ntawm thermoplastic system thaum lub xeev molten, zoo dua qhov kev sib kis ntawm cov fillers, txo qhov kev siv zog ntawm extrusion thiab txhaj tshuaj molding, thiab txhim kho kev tsim khoom; Ntawm qhov tod tes, cov khoom pab ua tiav raws li Silicone no kuj tseem tuaj yeem txhim kho qhov du ntawm cov khoom yas kawg, txo qhov sib txhuam ntawm qhov chaw thiab txhim kho qhov hnav thiab khawb tsis kam. Tsis tas li ntawd, ua cov khoom pab ua tiav rau kev lag luam thermoplastic, silicone masterbatch tuaj yeem ua tiav qhov kev hloov pauv pom tseeb nrog me me (< 5%), tsis tas yuav xav txog nws cov tshuaj tiv thaiv nrog cov khoom siv matrix.

Chengdu Silike Technology Co., Ltd. yog ib lub tuam txhab ua lag luam hauv Suav teb tshwj xeeb hauvcov khoom siv ntxiv uas ua los ntawm siliconerau cov lag luam yas thiab roj hmab. Nrog ntau tshaj 20 xyoo ntawm kev tshawb fawb mob siab rau kev sib xyaw ua ke ntawm silicone thiab polymers, Silike tau tsim nws tus kheej ua tus khub tshiab thiab ntseeg siab rau cov kev daws teeb meem ntxiv kev ua tau zoo.

Txhawm rau pab cov chaw tsim khoom hauv kev daws cov teeb meem kev tsim khoom ntsig txog LSZH cables, Silike tau tsim cov khoom lag luam tiav ntawmcov khoom siv ntxiv rau cov yas siliconetsim tshwj xeeb los txhim kho kev ua cov khoom sib xyaw cable. Cov khoom tseem ceeb, xws li Silicone Masterbatch LYSI-401 thiab Silicone Masterbatch LYSI-502C, muab cov kev daws teeb meem zoo uas tsom mus rau kev txhim kho kev ua haujlwm thiab qhov zoo ntawm qhov chaw, yog li pab txhawb rau kev ua tau zoo dua hauv kev siv hlau thiab cable.

Cov txiaj ntsig ntawm kev ua tau zoo: Cov txiaj ntsig ntawm kev sim ib txwm muaj ntawm Silicone Masterbatch hauv LSZH Cable Compounds

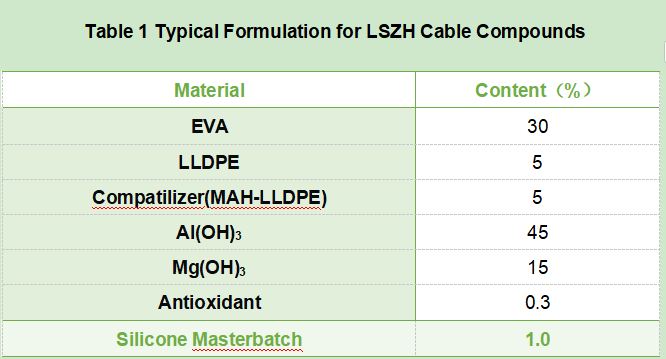

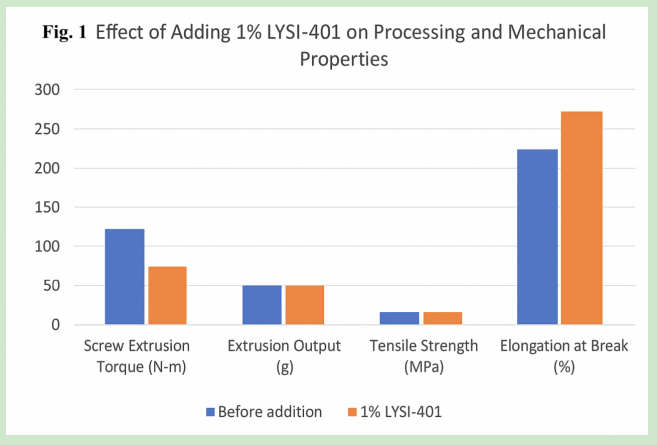

Ntxiv SILIKESilicone Masterbatch (Siloxane Masterbatch) LYSI seriesrau lub kaw lus puv hluav taws kub siab ntawm cov khoom siv cable uas tsis muaj pa luam yeeb halogen tsawg tuaj yeem txhim kho kev ua haujlwm fluidity, txo torque, thiab txhim kho kev ua haujlwm ntau lawm. Daim duab 1 qhia txog kev sib piv ntawm kev ua haujlwm cable tom qab ntxiv 1%LYSI-401 silicone masterbatchhauv peb lub tuam txhab cov qauv simulated dav dav uas tsis muaj pa luam yeeb halogen (Rooj 1). Nws tuaj yeem pom tias qhov kev ua tau zoo tau zoo dua qub.

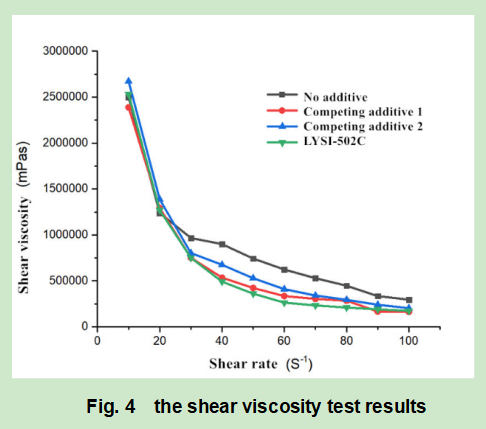

Daim Duab 2, Daim Duab 3, thiab Daim Duab 4 qhia qhov kev sim torque rheometer ntawm siloxane High ContentSilicone masterbatch LYSI-502Cntxiv rau cov mis tsis muaj pa luam yeeb tsawg thiab qhov sib piv nrog lub zog torque, siab, thiab shear viscosity ntawm cov khoom sib tw txawv teb chaws. Nws tuaj yeem pom tias LYSI-502C muaj kev ua haujlwm zoo heev.

Daim Duab 5 muab ib qho kev sim ua piv txwv muaj txiaj ntsig ntawm cov khoom siv sib sau ua ke hauv lub cable extrusion tuag tom qab ntxiv cov silicone masterbatch. Cov txiaj ntsig qhia tau hais tias kev suav nrog cov qauv silicone masterbatch txo qis kev tsim cov pwm. Ntxiv mus, SILIKE'ssilicone masterbatch hnyav molecular siabqhia txog qhov cuam tshuam ntau dua hauv kev txo qis kev sib sau ua ke ntawm cov pwm, qhia txog nws lub peev xwm rau kev ua haujlwm zoo dua.

Kev Txheeb Xyuas:Cov siloxane uas muaj nyob rau hauv tus qauvcov tshuaj silicone masterbatchesyog nonpolar, uas tuaj yeem tsim kev cov nyom vim muaj cov yam ntxwv sib txawv ntawm feem ntau cov pa roj carbon polymers. Thaum ntxiv ntau dhau, nws yuav ua rau muaj teeb meem xws li kev plam ntawm cov ntsia hlau, kev sib xyaw ntau dhau, kev tawg ntawm qhov chaw ntawm cov khoom, kev ua haujlwm sib txuas tsis zoo, thiab kev sib kis tsis sib xws hauv cov substrate.

Txhawm rau daws cov teeb meem no, SILIKE tau tsim ntau yamcov khoom siv silicone hnyav molecular siab heevuas tau hloov kho nrog cov pab pawg ua haujlwm tshwj xeeb. Cov nocov khoom siv ua cov polymer ua los ntawm siliconeCov khoom no yog tsim los ua kom tau raws li qhov xav tau ntawm ntau yam thermoplastic systems. Los ntawm kev ua haujlwm ua cov anchors hauv lub substrate, lawv txhim kho kev sib raug zoo, txhim kho kev sib kis, thiab txhawb kev sib txuas. Qhov no ua rau muaj kev ua tau zoo ntawm lub substrate. Hauv cov tshuab uas tsis muaj pa luam yeeb tsawg, tsis muaj halogen, cov khoom siv tshiab no tiv thaiv kev plam ntawm cov ntsia hlau thiab txo cov khoom siv tuag.

Koj puas tab tom nrhiav ib qhocov khoom siv ua polymertxhawm rau txhim kho koj cov txheej txheem tsim khoom LSZH cable?

Tshawb nrhiav seb SILIKE cov kev daws teeb meem masterbatch ua los ntawm silicone, suav nrog cov khoom siv silicone LYSI-401 thiab siloxane masterbatch LYSI-502C, tuaj yeem pab koj txhim kho kev tsim khoom, txo kev saib xyuas pwm, thiab ua tiav cov xov hlau zoo dua. Peb caw koj hu rau peb kom paub ntxiv thiab thov cov qauv.

Lub Vev Xaib: www.siliketech.com

Email: amy.wang@silike.cn

Lub sijhawm tshaj tawm: Lub Kaum Hli-10-2025