Txoj kev los tsim stain-resistant thiab mos-kov hluav taws xob txhuam hniav tuav tuav

Txoj kev tsim stain-resistant thiabsoft-kov electric toothbrushes tuav tes,

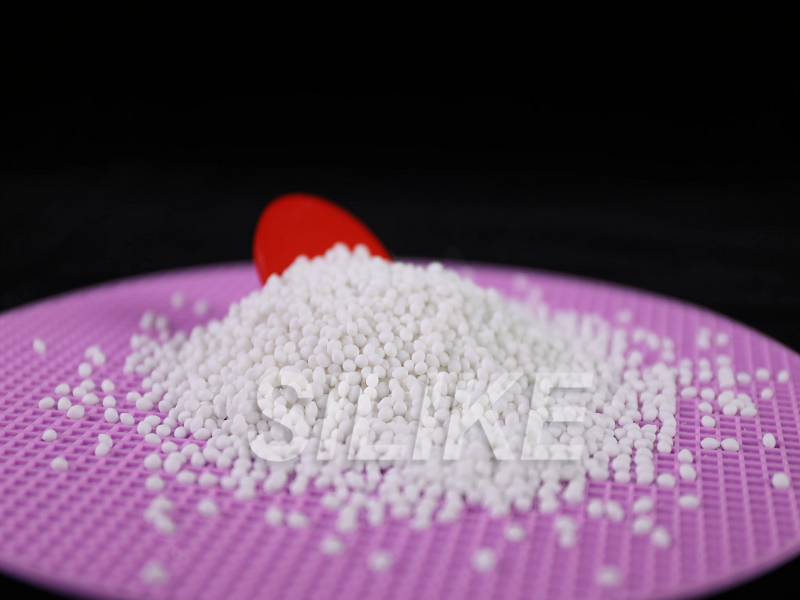

electric toothbrushes tuav tes, Silicone, SILIKE Si-TPV, soft-kov, Stain-resistant, TPE,

Kev piav qhia

SILIKE Si-TPV® thermoplastic elastomer yog patented dynamic vulcanized thermoplastic silicone-raws li elastomer uas ua los ntawm cov cuab yeej tshwj xeeb tshaj plaws los pab cov roj hmab silicone dispersed hauv TPU tusyees li 2 ~ 3 micron hais nyob rau hauv lub tshuab tsom. txhua yam thermoplastic elastomer nrog cov khoom tsim nyog ntawm silicone: softness, silky xav, UV teeb thiab tshuaj tiv thaiv uas tuaj yeem rov ua dua thiab rov siv dua hauv cov txheej txheem tsim khoom ib txwm muaj.

Si-TPV® 3520-70A thermoplastic elastomer yog cov khoom siv nrog zoo abrasion thiab soft silky xav uas tuaj yeem ua tau zoo heev rau PC, ABS, TPU thiab cov polar substrates zoo sib xws.Nws yog ib yam khoom tsim rau silky kov overmolding ntawm wearable electronics, accessory rooj rau electronics, saib bands.

APPLICATIONS

Kev daws teeb meem rau cov mos mos tshaj molding ntawm cov xov tooj ntse, portable electronic case, smartwatch wristband, straps, and other wearable electronic devices.

TSEEM CEEB

| Kuaj* | Khoom | Chav tsev | Kev tshwm sim |

| TS EN ISO 868 | Hardness (15 vib nas this) | Ntug A | 71 |

| TS EN ISO 1183 | Specific Gravity | - | 1.11 |

| TS EN ISO 1133 | Melt Flow Index 10 kg & 190 ° C | g/10 min | 48 |

| ISO 37 | MOE (Modulus ntawm elasticity) | MPa | 6.4 |

| ISO 37 | Tensile zog | MPa | 18 |

| ISO 37 | Tensile Stress @ 100% Elongation | MPa | 2.9 |

| ISO 37 | Elongation thaum so | % | 821 ib |

| ISO 34 | Tear Strength | kN / m | 55 |

| ISO 815 | Compression Teeb 22 teev @ 23 ° C | % | 29 |

* ISO: International Standardization Organization ASTM: American Society for Testing and Materials

NTA & KHOOM

(1) Mos silky xav

(2) Zoo khawb tsis kam

(3) Kev sib txuas zoo rau PC, ABS

(4) Super hydrophobic

(5) Stain resistance

(6) UV ruaj khov

YUAV UA LI CAS

• Phau Ntawv Qhia Kev Txhaj Tshuaj Molding

| Lub Sijhawm Qhuav | 2-6 teev |

| Qhuav kub | 80-100 ° C |

| Feed Zone Kub | 150-180 ° C |

| Center Zone Kub | 170-190 ° C |

| Front Zone Kub | 180-200 ° C |

| Nozzle kub | 180-200 ° C |

| Melt kub | 200 ° C |

| Pwm Kub | 20-40 ° C |

| Txhaj Ceev | Med |

Cov txheej txheem txheej txheem no yuav txawv nrog cov cuab yeej thiab cov txheej txheem.

• SecondaryKev ua haujlwm

Raws li cov khoom siv thermoplastic, Si-TPV® cov khoom siv tuaj yeem ua tiav rau cov khoom lag luam zoo tib yam

•Txhaj tshuajMouldingSiab

Kev tuav lub siab feem ntau nyob ntawm qhov geometry, thickness thiab qhov rooj qhov chaw ntawm cov khoom.Lub siab tuav yuav tsum tau teem rau tus nqi qis thaum xub thawj, thiab tom qab ntawd maj mam nce kom txog thaum tsis muaj qhov cuam tshuam txog kev pom ntawm cov khoom txhaj tshuaj molded.Vim yog cov khoom elastic ntawm cov khoom, ntau lub zog tuav yuav ua rau muaj kev deformation loj ntawm lub qhov rooj ntawm cov khoom.

• Rov qab siab

Nws raug pom zoo tias lub siab rov qab thaum lub ntsia hlau thim rov qab yuav tsum yog 0.7-1.4Mpa, uas yuav tsis tsuas yog ua kom muaj kev sib luag ntawm cov yaj yaj, tab sis kuj xyuas kom meej tias cov khoom tsis raug degraded los ntawm shear.Qhov pom zoo ntsia hlau ceev ntawm Si-TPV® yog 100-150rpm los xyuas kom meej qhov ua tiav melting thiab plasticization ntawm cov khoom tsis muaj cov khoom degradation los ntawm shear cua sov.

KEV KOM ZOO

Lub tshuab desiccant dehumidifying tshuab yog pom zoo rau txhua qhov ziab.

Cov ntaub ntawv kev nyab xeeb ntawm cov khoom xav tau rau kev siv nyab xeeb tsis suav nrog hauv daim ntawv no.Ua ntej tuav, nyeem cov khoom thiab cov ntaub ntawv kev nyab xeeb thiab cov ntawv ntim rau kev siv nyab xeeb, cov ntaub ntawv muaj kev phom sij rau lub cev thiab kev noj qab haus huv.cov ntaub ntawv kev nyab xeeb muaj nyob rau ntawm lub tuam txhab silike lub vev xaib ntawm siliketech.com, lossis los ntawm tus xa khoom, lossis hu rau Silike cov neeg siv khoom.

YUAV UA LI CAS YUAV TSUM TAU TXAIS LUB SIJ HAWM

Thauj raws li cov tshuaj tsis muaj teeb meem.Khaws rau hauv qhov chaw txias, zoo ventilated.Cov yam ntxwv tseem ceeb nyob twj ywm rau 24 lub hlis txij li hnub tsim khoom, yog tias khaws cia hauv kev pom zoo cia.

KEV PAB CUAM

25KG / hnab, khoom siv tes ua hnab nrog PE puab lub hnab.

TXOJ CAI

Cov khoom no tsis raug kuaj los yog sawv cev raws li tsim nyog rau kev kho mob lossis kev siv tshuaj.

LIMITED WARRANTY INFORMATION - Thov nyeem ua tib zoo nyeem

Cov ntaub ntawv muaj nyob ntawm no yog muab rau hauv kev ntseeg zoo thiab ntseeg tau tias muaj tseeb.Txawm li cas los xij, vim tias cov xwm txheej thiab cov txheej txheem ntawm kev siv peb cov khoom yog dhau ntawm peb txoj kev tswj hwm, cov ntaub ntawv no yuav tsum tsis txhob siv los hloov cov neeg siv khoom cov kev ntsuam xyuas kom ntseeg tau tias peb cov khoom muaj kev nyab xeeb, ua tau zoo, thiab txaus siab rau kev siv kawg.Cov lus qhia ntawm kev siv yuav tsum tsis txhob muab coj los ua induces ua txhaum ib qho patent.

Hluav taws xob txhuam hniav, tuav tuav yog feem ntau yog ua los ntawm engineering yas xws li ABS, PC / ABS, thiaj li yuav pab kom lub pob khawm thiab lwm qhov chaw kom ncaj qha mus cuag tes nrog zoo txhais tes, lub zog kov yog feem ntau encapsulated los ntawm cov roj hmab mos, lub common soft rubber yogTPE, TPU los yog silicone, uas cov attractiveness thiab tes zoo nkaus li ntawm cov khoom txhaj tshuaj tuaj yeem txhim kho.Tab sis, silicone los yog lwm yam nplaum nplaum yog siv thiab ua ke nrog engineering plastics nyob rau hauv ib tug kua nplaum daim ntawv cog lus hom, cov kauj ruam yog complex, lub uncontrollable kev ua tau zoo yog siab, nruam ntau lawm yog tsis yooj yim sua kom ua tau zoo, thiab thaum lub sij hawm lub tswv yim xeem, cov kua nplaum yuav hydrolyzed. nyob rau hauv cov teebmeem ntawm cov tshuaj txhuam hniav dej, tshuaj ntxuav qhov ncauj los yog lub ntsej muag ntxuav cov khoom, uas cov kua nplaum mos thiab tawv yog yooj yim degum.

Txawm li cas los xij,SILIKE Si-TPVyog siv rau kev txhaj tshuaj molding ntawm engineering yas rau hluav taws xob txhuam hniav tuav tuav.thiab cov khoom txhaj tshuaj tuaj yeem ua tsis tu ncua.

DAWB SILICONE ADDITIVES THIAB Si-TPV cov qauv ntau dua 100 qib

Hom qauv

$0

- 50+

Qib Silicone Masterbatch

- 10+

Qib Silicone Powder

- 10+

Qib Anti-scratch Masterbatch

- 10+

Qib Anti-abrasion Masterbatch

- 10+

Qib Si-TPV

- 8+

qib Silicone Wax

-

Xov tooj

-

E-mail

-

WeChat

-

Sab saum toj

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur